Wind turbine blade made from shape memory fiber hybrid composite material and manufacturing method of wind turbine blade

A technology of wind turbines and memory fibers, applied in wind turbines, engines, engine components, etc., can solve the problems of blade flutter, wind turbine blade flutter, reduce wind turbine blade vibration, etc., to solve the problems of flutter, cost, etc. Inexpensive, vibration-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

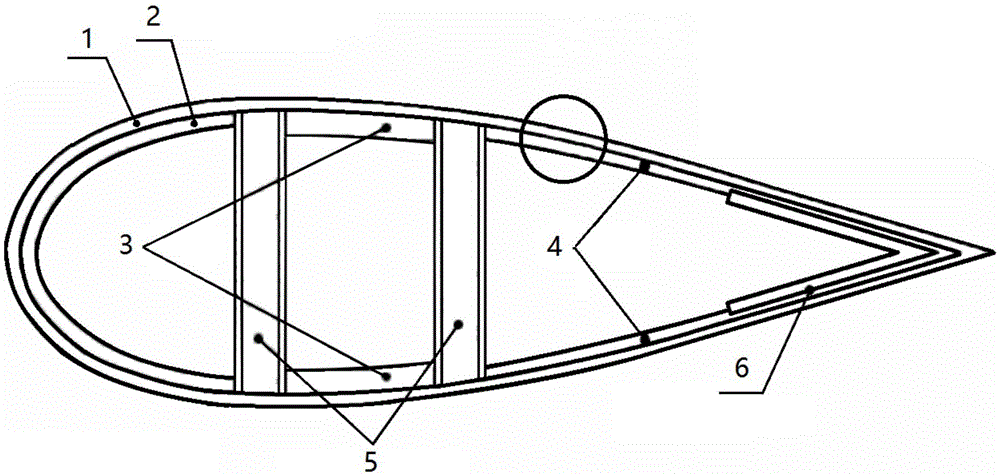

[0022] The following examples refer to Figure 1-3 .

[0023] device embodiment.

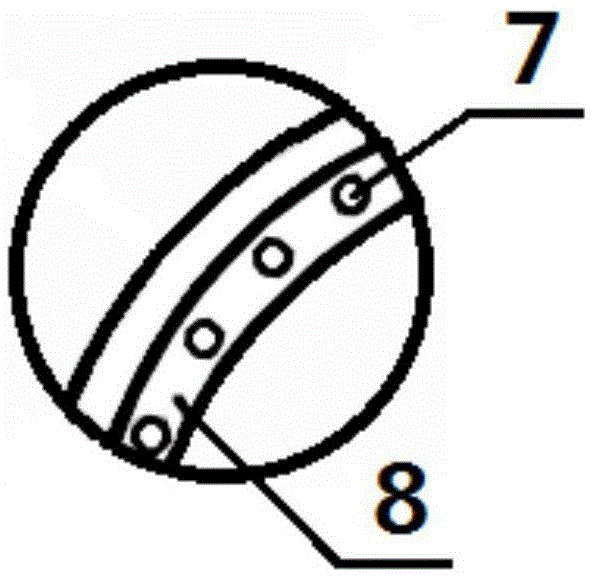

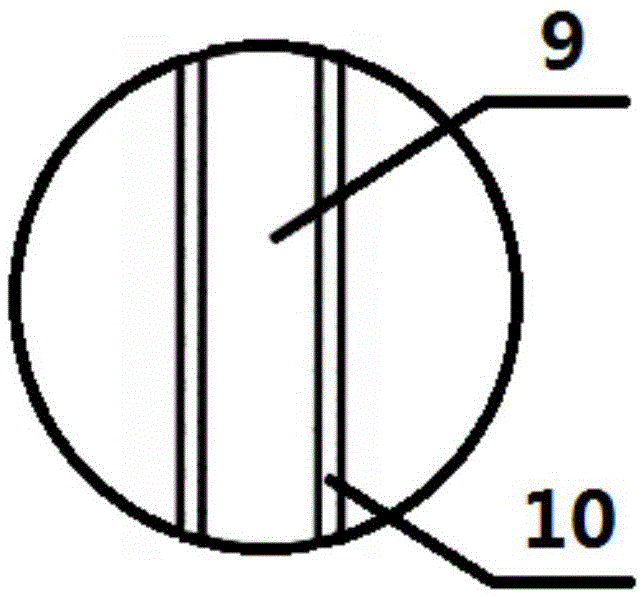

[0024] The shape memory fiber hybrid composite wind power generator blade of the present invention includes an outer skin 1 , a leading edge plate 2 , a beam cover 3 , a trailing edge plate 4 , a shear web 5 and a tail plate 6 . The outer skin 1 is made of glass fiber reinforced composite material, the front edge panel 2 and the rear edge panel 4 are made of memory shape memory fiber fabric 7 and matrix resin 8, and the beam cover 3 is made of unidirectional fiber reinforced composite material , the shear web 5 is formed by bonding a superelastic shape memory fiber strip 10 and a core glass fiber resin matrix composite material 9, and the tail plate 6 is made of a glass fiber reinforced composite material. The front edge plate 2 and the outer skin 1 are bonded with epoxy resin to form the front half of the blade, the tail plate 6 and the trailing edge plate 4, and the trailing edge plate 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com