Electron supply system

An electronic supply and electronic technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as covering ion beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

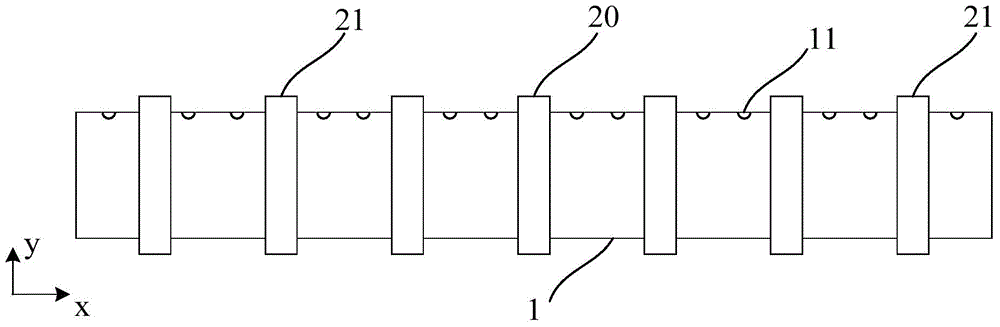

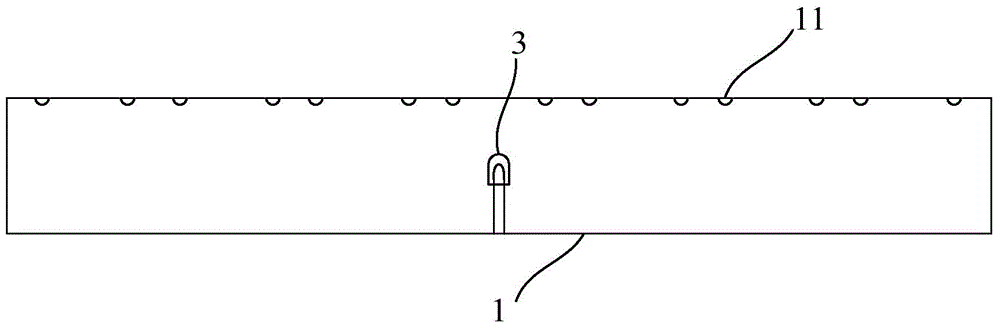

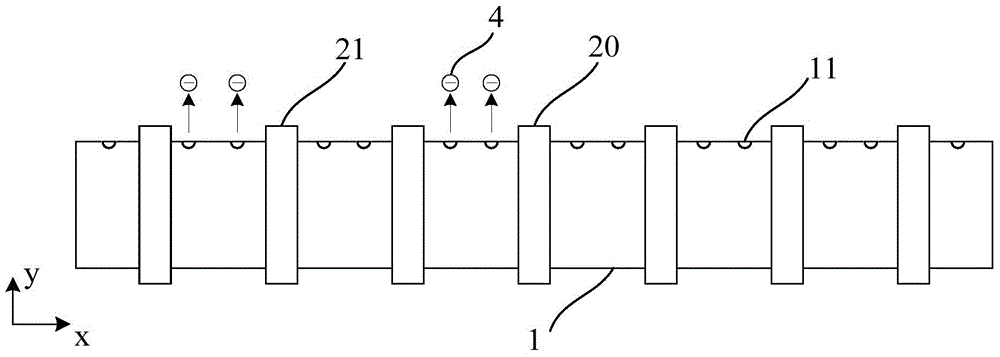

[0046] refer to figure 1 and figure 2 , the electron supply system described in this embodiment includes a cavity 1, which is filled with gas, and the side wall of the cavity 1 is provided with extraction units distributed along the length direction (x direction) of the cavity, In this embodiment, the extraction unit is a plurality of through holes 11 arranged along the x direction, and a cathode 3 is arranged in the cavity 1, and the cathode 3 is used to emit electrons.

[0047] The electron supply system also includes a plurality of magnetic devices 20, 21 surrounding the cavity (the magnetic device corresponding to the cathode position is indicated by 20, and the other magnetic devices located on both sides of the magnetic device 20 are indicated by 21), a plurality of The magnetic devices are arranged at intervals along the length direction of the cavity, and the superimposed magnetic field of these magnetic devices makes: in the cavity, electrons can be distributed in t...

Embodiment 2

[0055] The basic principle of embodiment 2 is the same as that of embodiment 1, the only difference is:

[0056] In this embodiment, the lead-out unit is a strip-shaped slot hole, the length direction of the slot hole is consistent with the length direction of the cavity, and the magnetic device is an electromagnet, and the current on the coil of the electromagnet is adjustable. .

[0057] Refer to Example 1 for all the other unmentioned parts.

Embodiment 3

[0059] The basic principle of embodiment 3 is the same as embodiment 1, the only difference is:

[0060] In this embodiment, the number of the cathode is one. In the length direction of the cavity, the cathode is placed in the middle of the cavity, and the installation positions of the magnetic devices are axisymmetrically distributed, and the axis of symmetry is perpendicular to the cavity. in the lengthwise direction and through the cathode,

[0061] Wherein, in the length direction of the cavity, from the cathode to the direction away from the cathode, the magnetic field strength of the magnetic device decreases successively, and some electrons move from the position with strong magnetic field strength to the position with weak magnetic field along the length direction of the cavity. positional movement,

[0062] And the magnetic field formed by two adjacent magnetic devices enables another part of electrons to be confined in the space between the two adjacent magnetic dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com