Perovskite film preparation method and application

A perovskite and lead source technology, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve problems such as changing the stoichiometric ratio of perovskite films, difficult to control the reaction process, and affecting performance. The effect of low cost, improved performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 (one-step solution spin-coating method, comparative example)

[0054] will be sputtered with fluorine-doped SnO 2 (FTO) transparent conductive glass was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol in sequence, blown dry with nitrogen gas, and immediately put it into an ultraviolet ozone surface treatment equipment (UVO) for 15 minutes, and then The PEDOT:PSS solution was spin-coated at 3000 rpm, and thermally annealed at 150° C. in air for 15 minutes to obtain a hole transport layer with a thickness of about 30 nm. Then PbI 2 and CH 3 NH 3 I is dissolved in the DMF (N,N-methylformamide) solution in a molar ratio of 1:1, and PbI in the solution 2 and CH 3 NH 3 The mass concentration of I was 45wt%, and the perovskite precursor solution was obtained by heating at 70° C. for 5 h. The perovskite precursor solution was spin-coated on the hole transport layer at a speed of 5000 rpm. Thermal annealing f...

Embodiment 2

[0056] Embodiment 2 (two-step solution spin-coating method, comparative example)

[0057] will be sputtered with fluorine-doped SnO 2 (FTO) transparent conductive glass was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol in sequence, blown dry with nitrogen gas, and immediately put it into an ultraviolet ozone surface treatment equipment (UVO) for 15 minutes, and then The PEDOT:PSS solution was spin-coated at 3000 rpm, and thermally annealed at 150° C. in air for 15 minutes to obtain a hole transport layer with a thickness of about 30 nm. Then PbI at a concentration of 350mg / ml 2 and 40mg / ml of CH 3 NH 3 I was dissolved in DMF (N,N-methylformamide) and isopropanol solution respectively, and stirred for 5 h to obtain a precursor solution. PbI 2 The solution was spin-coated on the hole transport layer at a speed of 1800rpm, and thermally annealed for 10-15min to obtain PbI 2 film. After CH 3 NH 3 A solution of I was spin...

Embodiment 3

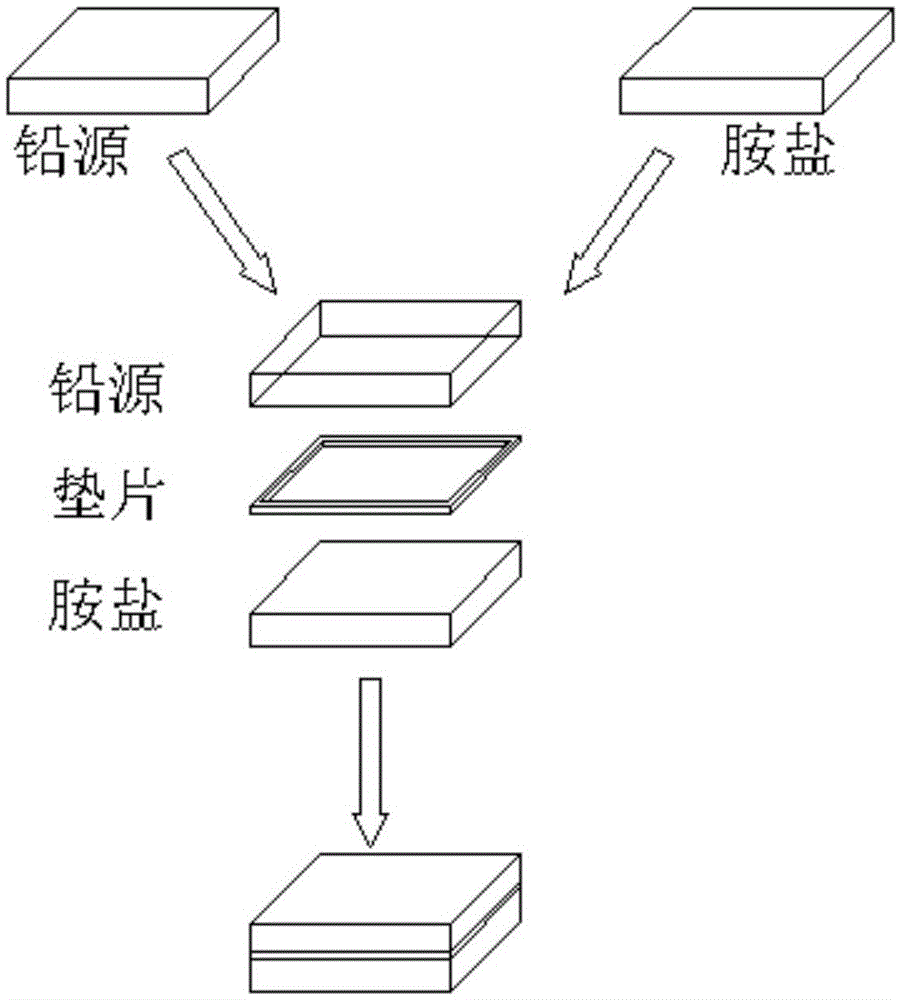

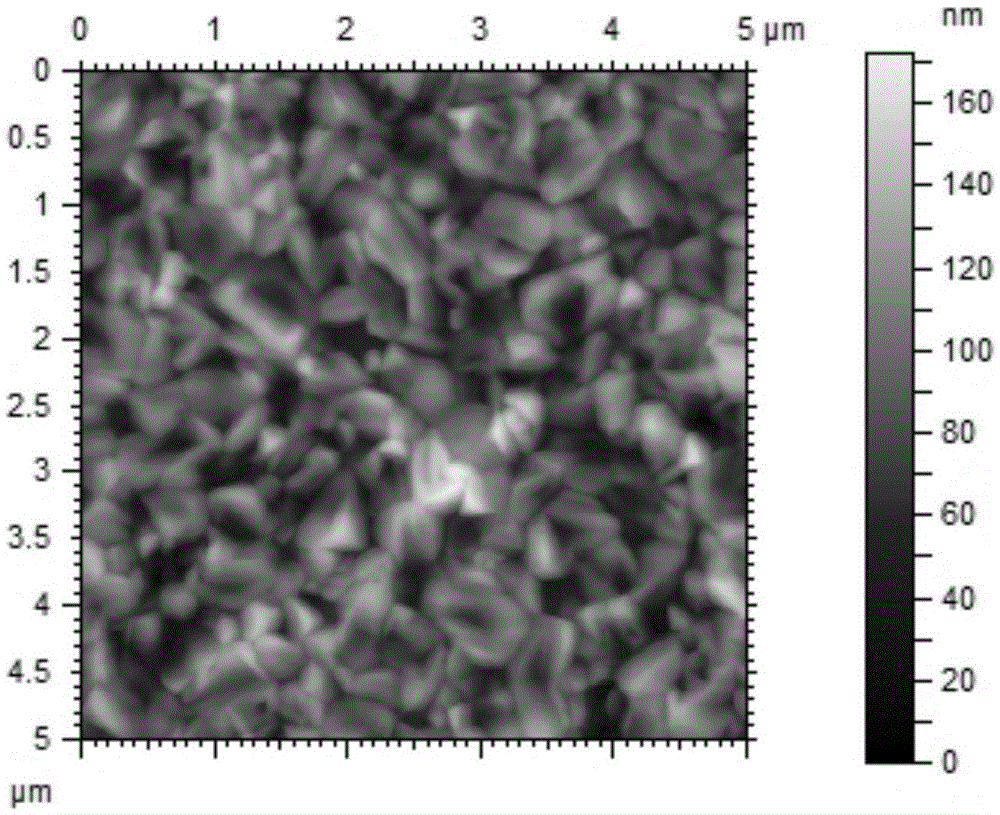

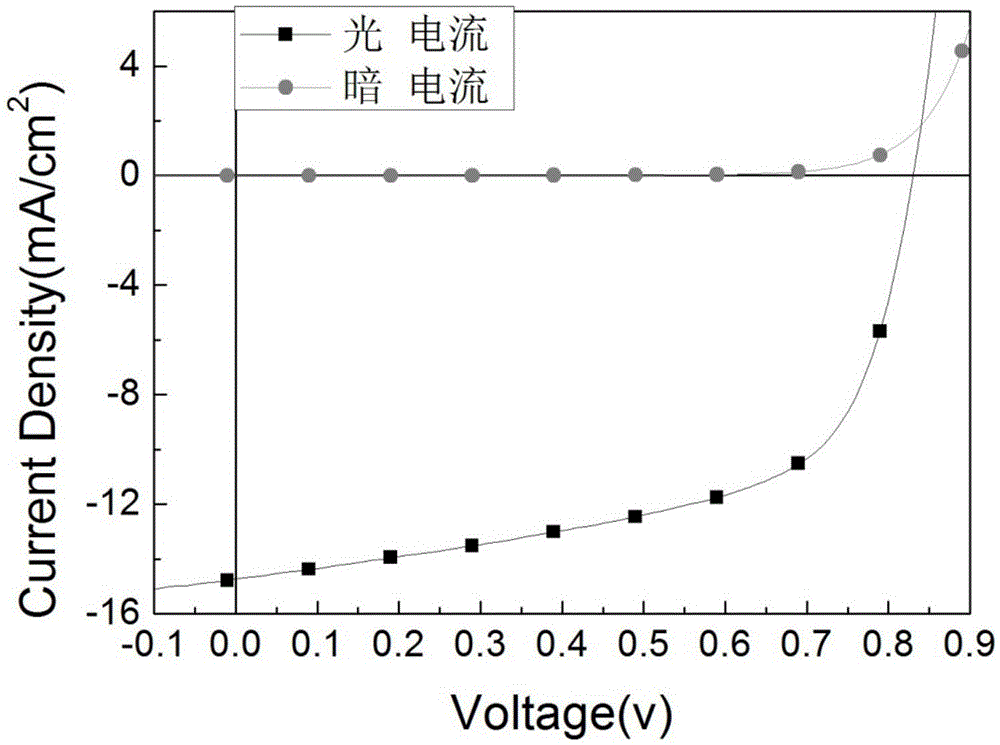

[0059] Embodiment 3 (near space sublimation method)

[0060] will be sputtered with fluorine-doped SnO 2 (FTO) transparent conductive glass was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol in sequence, blown dry with nitrogen gas, and immediately put it into an ultraviolet ozone surface treatment equipment (UVO) for 15 minutes, and then The PEDOT:PSS solution was spin-coated at 3000 rpm, and thermally annealed at 150° C. in air for 15 minutes to obtain a hole transport layer with a thickness of about 30 nm. Then PbI at a concentration of 350mg / ml 2 and 40mg / ml of CH 3 NH 3 I was dissolved in DMF (N,N-methylformamide) and isopropanol solution respectively, and stirred for 5 h to obtain a precursor solution. PbI 2 The solution was spin-coated on the hole transport layer at a speed of 1800rpm, and thermally annealed for 10-15min to obtain PbI 2 film. CH 3 NH 3 Solution I was spin-coated on FTO glass at 1100rpm, and ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com