Method for recycling sulfur in wastewater by microbial fuel cell

A technology of fuel cells and microorganisms, which is applied to the disposal/recycling of fuel cells, biochemical fuel cells, fuel cells, etc., and can solve the problems of not being able to recover the energy of sulfur pollutants, so as to avoid the addition of high-cost catalysts and realize the recovery of electric energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

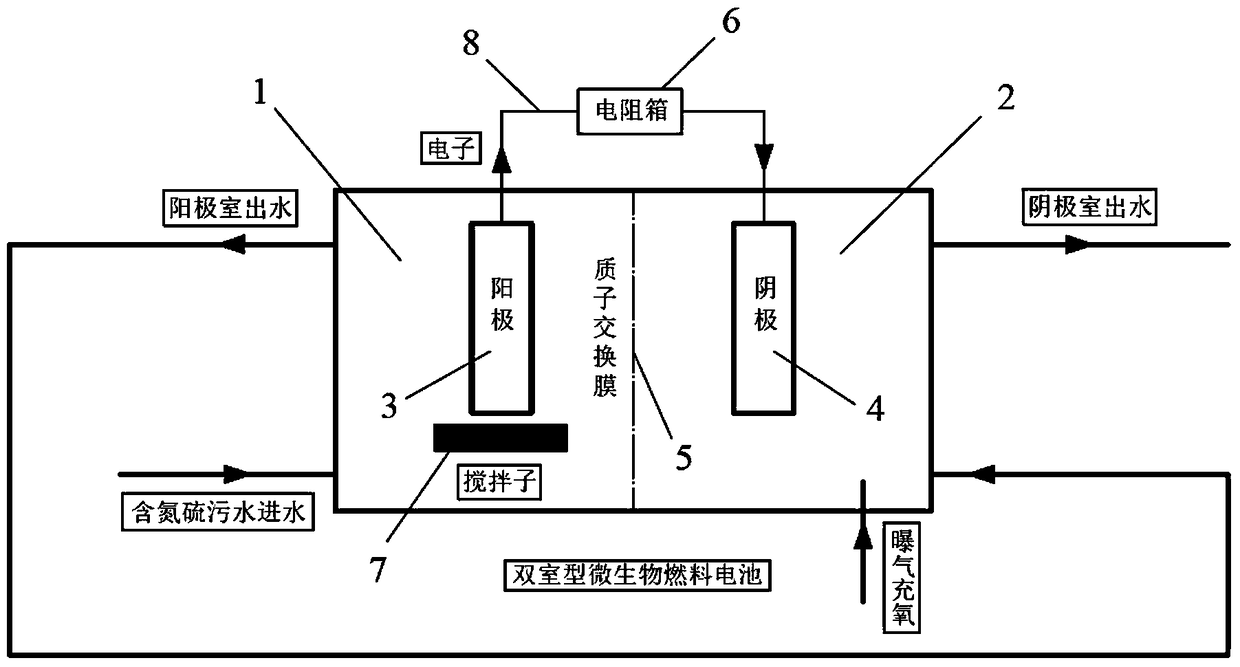

[0045] The dual-chamber microbial fuel cell used in this test has an effective volume of 200ml for each chamber of the cathode and anode, and the device uses graphite fiber as the electrode material. Before the operation of the microbial fuel cell, the cathode graphite fiber filaments are soaked in aerobic sludge to absorb microorganisms. After a period of time, the corresponding microorganisms can be propagated and enriched on the anode and cathode, and the anode is not inoculated with sludge. The dual-chamber microbial fuel cell operates intermittently at 25° C., the operating cycle is 12 hours, 200 ml of water is fed each time, and the resistance of the external circuit is set to 100Ω. The specific operation is as follows:

[0046] 1) The sewage containing sulfide (64mgS / L) and ammonia nitrogen (27.2mgN / L) is injected into the anode chamber of the microbial fuel cell through a peristaltic pump.

[0047] 2) The sulfides are oxidized in the anode chamber mainly through self-...

Embodiment 2

[0053] The dual-chamber microbial fuel cell used in this test has an effective volume of 200ml for each chamber of the cathode and anode, and the device uses graphite fiber as the electrode material. Before the operation of the microbial fuel cell, the cathode graphite fiber filaments are soaked in aerobic sludge to absorb microorganisms. After a period of time, the corresponding microorganisms can be propagated and enriched on the anode and cathode, and the anode is not inoculated with sludge. The dual-chamber microbial fuel cell operates intermittently at 25° C., the operating cycle is 12 hours, 200 ml of water is fed each time, and the resistance of the external circuit is set to 100Ω. The specific operation is as follows:

[0054] 1) The sewage containing sulfide (128mgS / L) and ammonia nitrogen (27.2mgN / L) is injected into the anode chamber of the microbial fuel cell through a peristaltic pump.

[0055] 2) The sulfides are oxidized in the anode chamber mainly through self...

Embodiment 3

[0061] The dual-chamber microbial fuel cell used in this test has an effective volume of 200ml for each chamber of the cathode and anode, and the device uses graphite fiber as the electrode material. Before the operation of the microbial fuel cell, the cathode graphite fiber filaments are soaked in aerobic sludge to absorb microorganisms. After a period of time, the corresponding microorganisms can be propagated and enriched on the anode and cathode, and the anode is not inoculated with sludge. The dual-chamber microbial fuel cell operates intermittently at 25° C., the operating cycle is 12 hours, 200 ml of water is fed each time, and the resistance of the external circuit is set to 100Ω. The specific operation is as follows:

[0062] 1) The sewage containing sulfide (192mgS / L) and ammonia nitrogen (27.2mgN / L) is injected into the anode chamber of the microbial fuel cell through a peristaltic pump.

[0063] 2) The sulfides are oxidized in the anode chamber mainly through self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com