Torque transmission shaft with yoke for universal joint and manufacturing method therefor

A technology for universal joints and manufacturing methods, which is applied to steering control, shafts, and applications installed on vehicles, and can solve problems such as the difficulty in reducing the weight of the intermediate shaft 5 and increasing manufacturing costs, so as to ensure strength and suppress manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

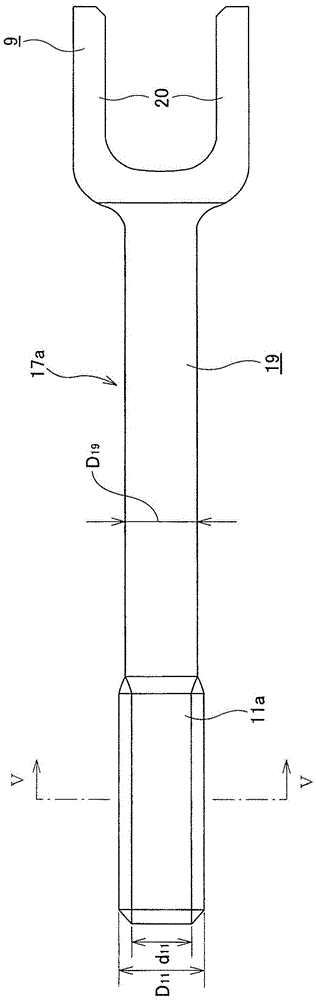

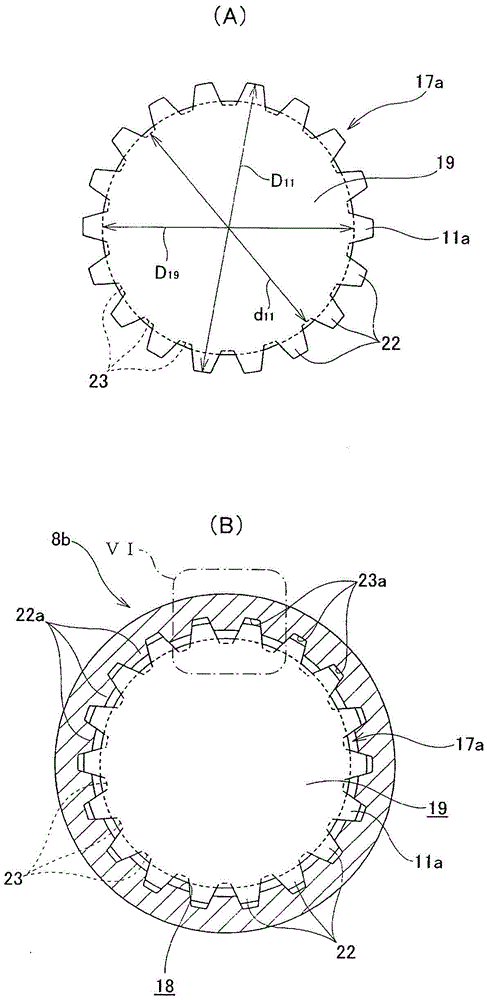

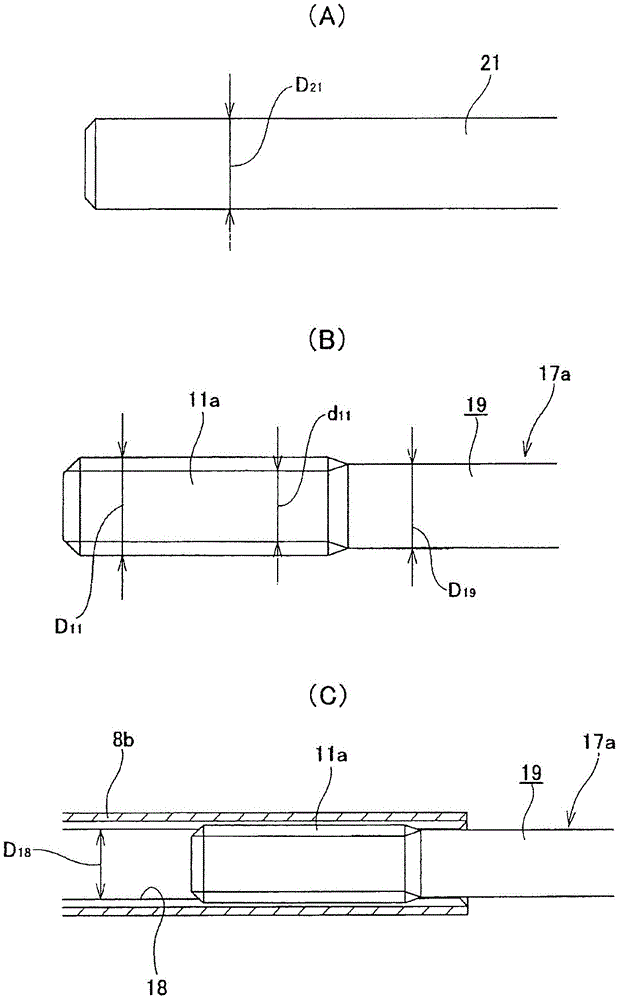

[0077] use Figure 1-7 The first embodiment of the present invention will be described. figure 1 The completed state of the torque transmission shaft 17a with the yoke for universal joints of this embodiment is shown. A torque transmission shaft 17a with a yoke for a universal joint is at one axial end ( figure 1 A male spline portion 11a is provided on the outer peripheral surface of the left end portion of the rod portion 19, and the other axial end portion of the rod portion 19 ( figure 1 The right end portion of the fork yoke 9) is fixedly provided with a base end portion of a yoke 9 having a cross shaft 10 for constituting a cross shaft universal joint 4a (refer to Figure 12 A pair of arm portions 20, 20 pivotally supported by two end portions on radially opposite sides among the four end portions provided on ). In particular, in the case of the torque transmission shaft 17a with the yoke for a universal joint according to this embodiment, the groove bottom diamete...

no. 2 Embodiment approach

[0089] use Figure 8-9 A second embodiment of the present invention will be described. Figure 8 A state in which the torque transmission shaft 17b with the yoke for universal joints of this embodiment is combined with the torque transmission shaft 8b to form the intermediate shaft 5 is shown. Moreover, the torque transmission shaft 17b with the yoke for universal joints of this embodiment is characterized by the structure of the coating layer 24c made of a low-friction material provided on the surface of the male spline part 11a. The structure and manufacturing method of the other parts are the same as those of the torque transmission shaft 17a with a yoke for a universal joint in the first embodiment described above, so the following description will focus on the structure of the coating layer 24c.

[0090] In the case of the present embodiment, the covering layer 24c is formed over the entire length and the entire circumference of the male spline portion 11a. In the cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com