Production technology of precise stainless steel bright pipe

A production process, stainless steel technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipes, etc., can solve the problems of low production efficiency and complex production process, and achieve the effect of high production efficiency, simple process steps and superior performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

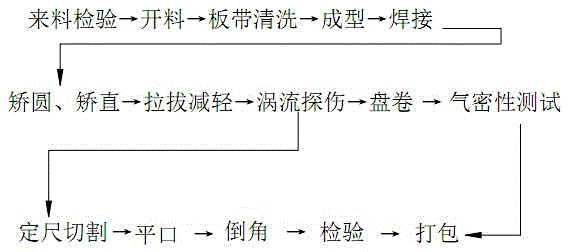

[0009] refer to figure 1 , the present specific embodiment adopts the following technical solutions: a precision stainless steel bright tube production process, which includes the following steps: 1, incoming material inspection; 2, cutting: first carry out cutting processing by a cutting machine; : Carry out strip cleaning treatment by acid; 4. Forming and welding; 5. Rounding and straightening: Carry out rounding and straightening operations on the formed bright tube; 6. Then carry out the drawing and reducing process in sequence; 7. After the eddy current flaw detection, carry out the coiling and length cutting operations respectively; 8. After the coiling, carry out the air tightness test, and finally carry out the packaging operation; 9. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com