Automatic log bark removing machine and using method thereof

A peeling machine, automatic technology, applied in the direction of bark, wood processing equipment, manufacturing tools, etc., can solve the problems of affecting normal use, general peeling effect, low work efficiency, etc., to achieve simple structure, easy subsequent processing, Guaranteed peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

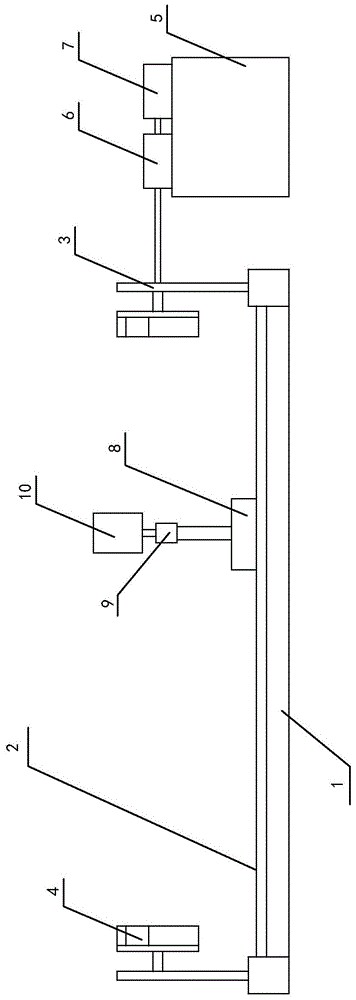

[0031] Such as Figure 1~3 As shown, the automatic log peeling machine includes a frame body 1, a conveyor belt 2 is provided on one side of the top of the frame body 1, fixed rods 3 are respectively symmetrically arranged at both ends of the frame body 1, and the inner sides of the two fixed rods 3 are correspondingly movable. Fixed component 4;

[0032] The right side of the frame body 1 is provided with a motor fixing table 5, and the motor fixing table 5 is provided with a reducer 6 and a motor 7, and the fixing assembly 4 on the right side is connected with the reducer 6 and the motor 7 in turn;

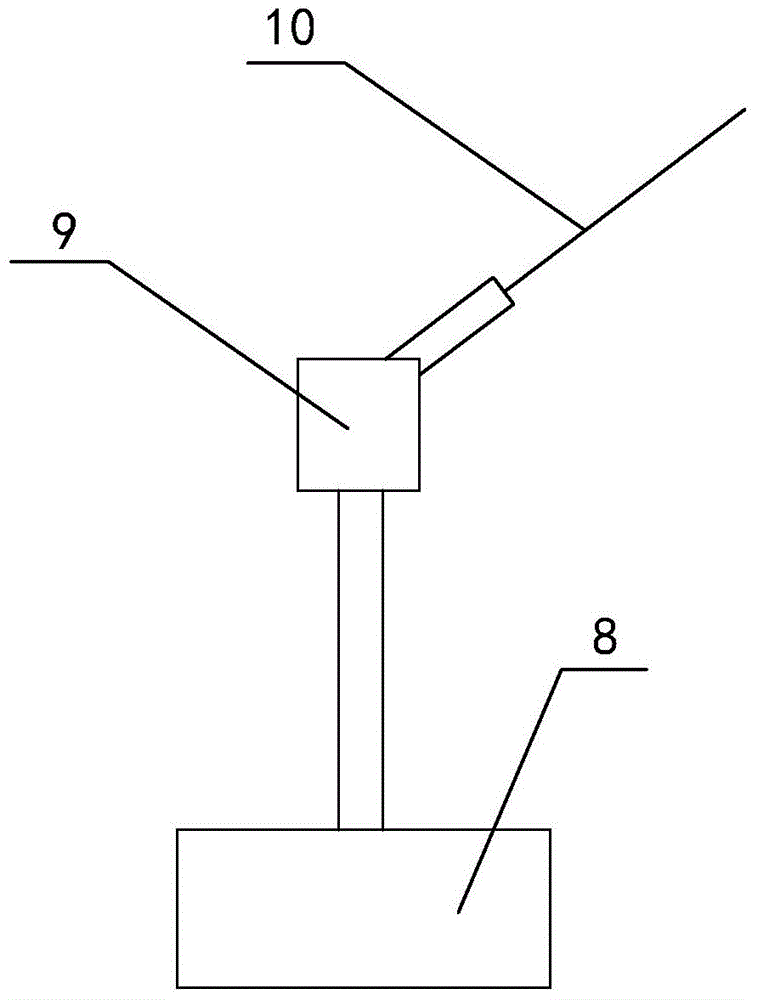

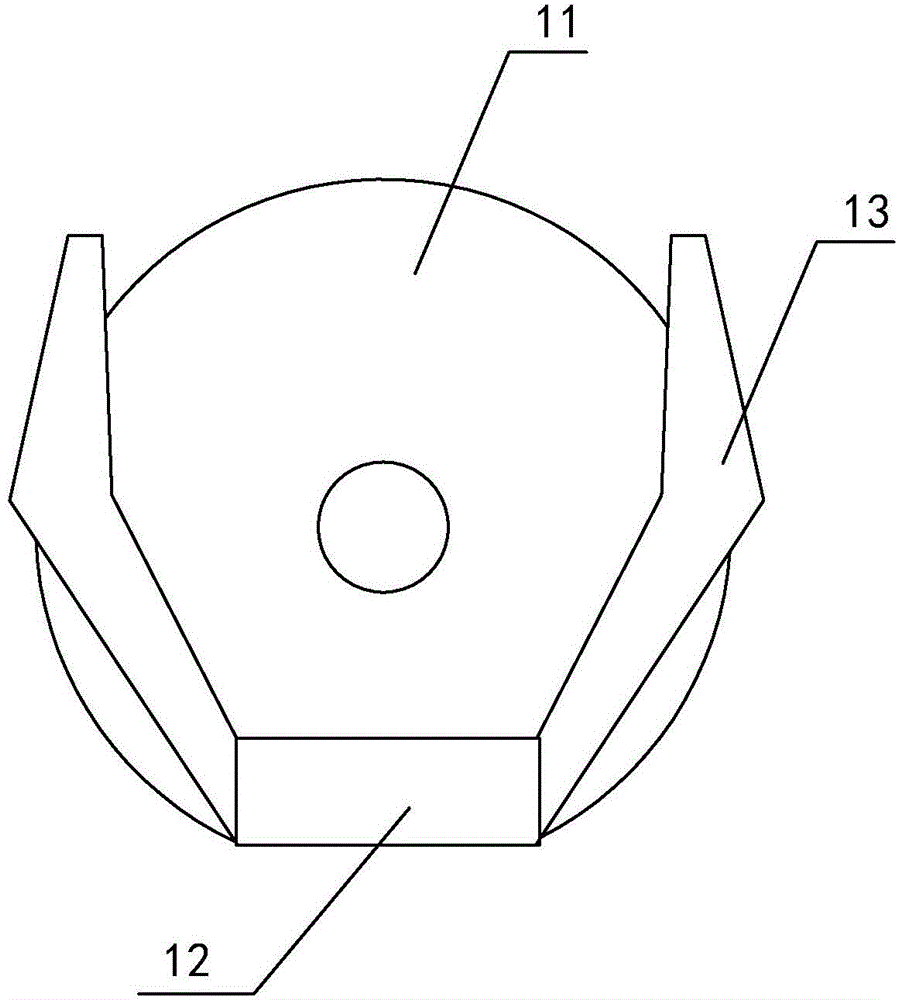

[0033] The conveyor belt 2 is provided with a peeling knife fixing table 8, and the top of the skin knife fixing table 8 is fixed with a peeling knife 10 through a rotating assembly 9;

[0034] The conveyor belt 2, the reducer 6, the motor 7 and the rotating ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com