Plastic tube welding protection opening

A plastic tube and tube shape technology, which is applied in the direction of non-detachable tube connections, tubes/pipe joints/fittings, passing components, etc., can solve the problems of not reaching the circular limit threshold, short correction time, and increased material costs. , to achieve the effect of avoiding melt loss, excellent sealing performance and strengthening sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

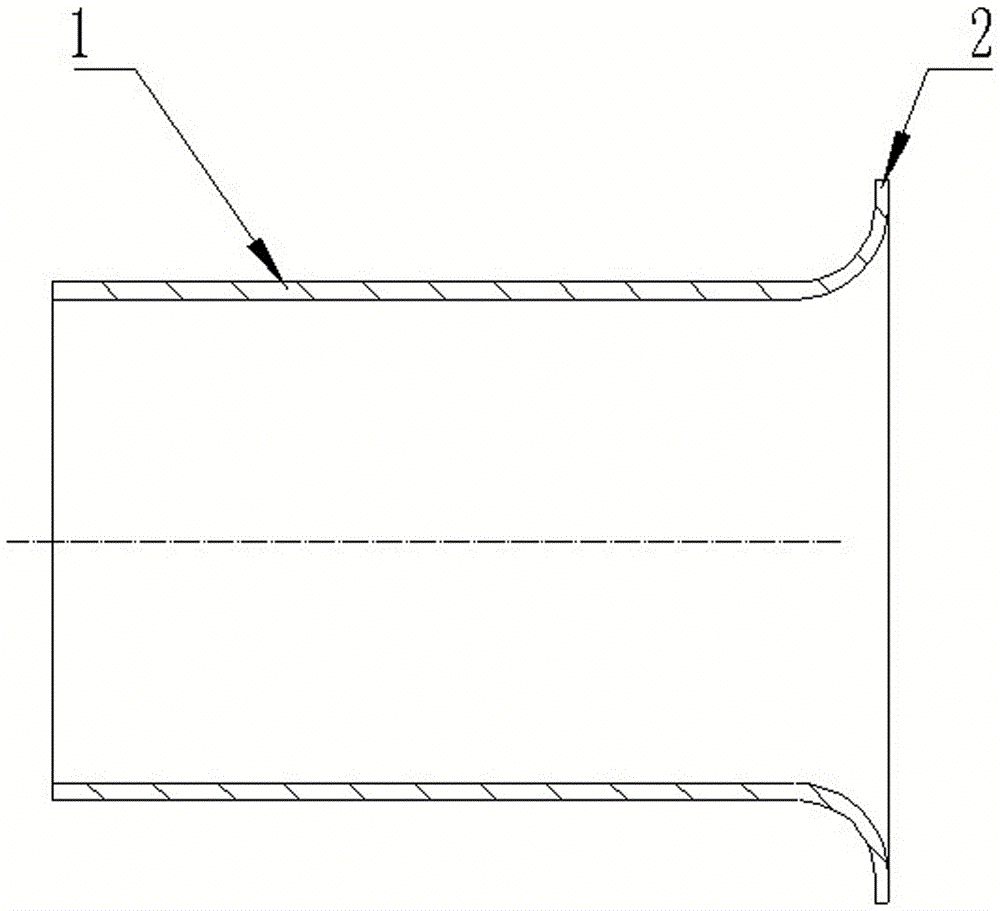

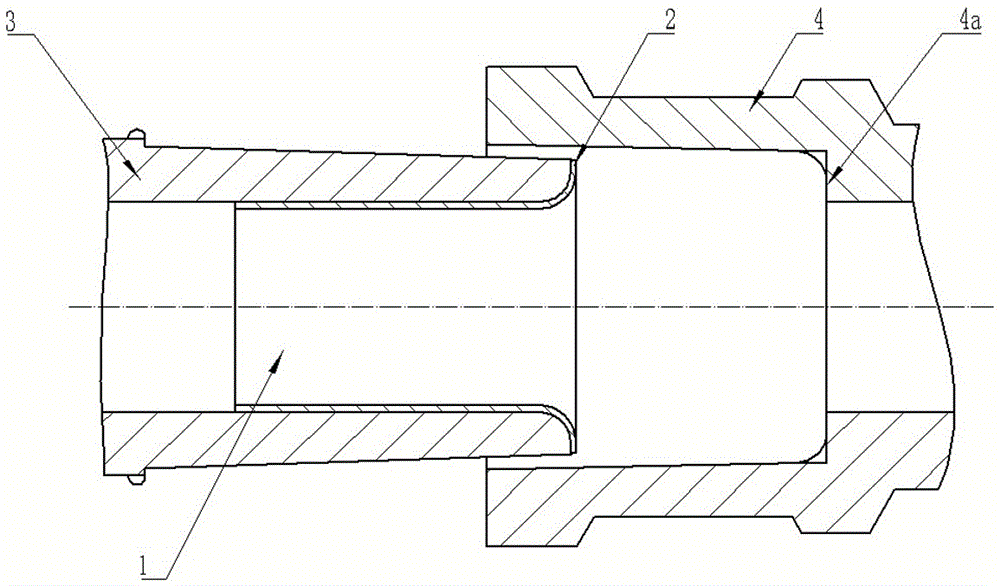

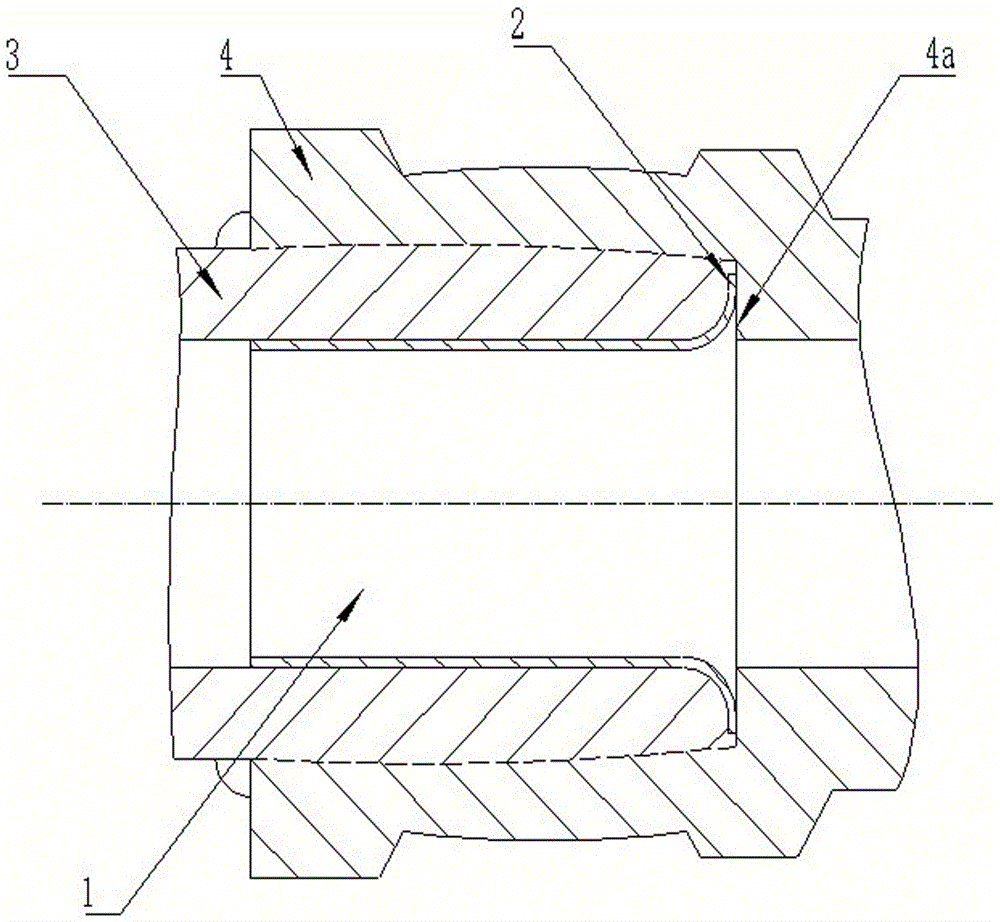

[0018] Such as figure 1 , figure 2 , image 3 As shown, a plastic pipe welding mouth guard of the present invention is composed of an integrally formed tubular liner 1 and a trumpet-shaped cornice 2 .

[0019] The outer diameter of the tubular liner 1 is equal to the inner diameter of the circular stopper 4a or slightly smaller than the inner diameter of the plastic pipe socket 3; the outer diameter of the trumpet-shaped cornice 2 is slightly smaller than the outer diameter of the plastic pipe socket 3.

[0020] When the present invention is used in water supply engineering construction, its size matches the operation object. During the specific operation, the present invention is first embedded in the plastic pipe socket 3 to be welded, and a positioning line is drawn on its outer wall according to the depth of the pipe fitting socket 4; 2 Close to the mouth edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com