Low-density carbon fiber hard insulation quilt and preparation method thereof

A technology of rigid thermal insulation felt and carbon fiber, which is applied to chemical instruments and methods, protective equipment, and other household appliances. It can solve the problems of high production cost, high longitudinal fiber content, and many materials, so as to achieve good thermal insulation performance and improve thermal insulation. performance, the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of low-density carbon fiber rigid insulation felt, the steps are as follows:

[0033] (1) Use polyacrylonitrile-based carbon fiber with a carbon content ≥ 92% as raw material, cut the carbon fiber into 3-30mm, comb it into wool with a carding machine and make it into a net tire, and the weight of the net tire is 50g / m 2 , thickness is 4mm, density is 0.06g / cm 3 , the carbon fiber arrangement direction is basically consistent with the plane where the mesh tire is located;

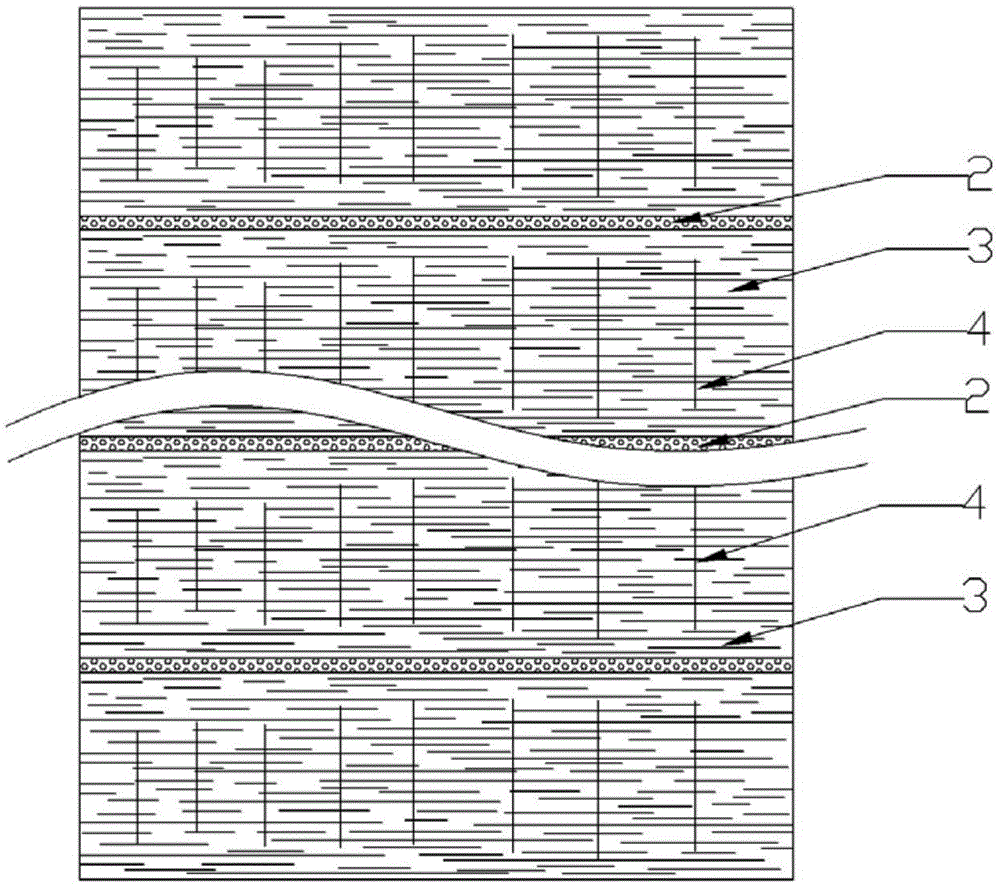

[0034] (2) Use acupuncture method to combine 8 layers of mesh tires into a mesh tire unit, and the density of needle punching is 3-30 needles / cm 2 ; The needle punching direction is longitudinal, and the mesh tire unit laying direction is horizontal, that is, the needle punching direction is perpendicular to the plane where the mesh tire unit is located.

[0035] (3) Adopt mist spraying method to carry out one-sided or double-sided spraying phenolic resin adhesive to the net tir...

Embodiment 2

[0043] A preparation method of low-density carbon fiber rigid insulation felt, the steps are as follows:

[0044] (1) Use polyacrylonitrile-based carbon fiber with a carbon content ≥ 92% as raw material, cut the carbon fiber into 3-30mm, comb it into wool with a carding machine and make it into a net tire, and the weight of the net tire is 100g / m 2 , thickness is 4mm, density is 0.07g / cm 3 , the carbon fiber arrangement direction is basically consistent with the plane where the mesh tire is located;

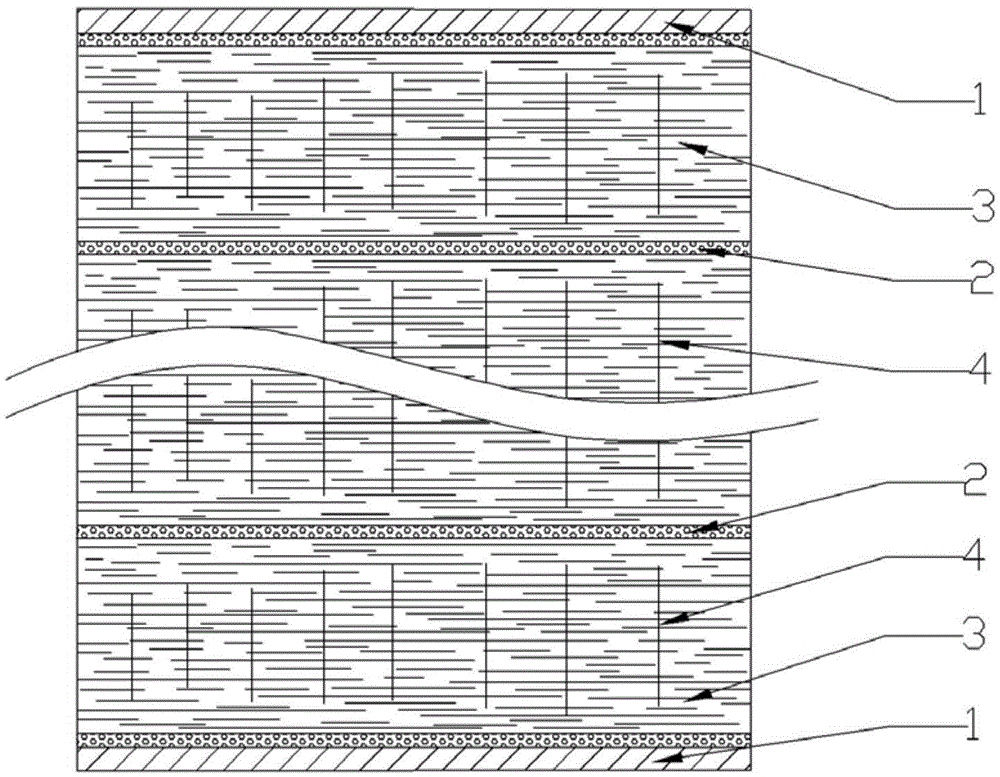

[0045] (2) Using the acupuncture method, 8 layers of mesh tires are needled and compounded into a mesh tire unit, and the density of needle punching is 15-20 needles / cm; The stabbing direction is perpendicular to the plane where the mesh tire unit is located.

[0046] (3) Use the mist spraying method to carry out single-sided or double-sided spraying of phenolic resin adhesive to the net tire unit made above, and the amount of glue sprayed is 1.0kg / m 2 ;

[0047] (4) Put 0.5m...

Embodiment 3

[0054] A preparation method of low-density carbon fiber rigid insulation felt, the steps are as follows:

[0055] (1) Use polyacrylonitrile-based carbon fiber with a carbon content ≥ 92% as raw material, cut the carbon fiber into 3-30mm, comb it into wool with a carding machine and make it into a net tire, and the weight of the net tire is 100g / m 2 , thickness is 4mm, density is 0.07g / cm 3 , the carbon fiber arrangement direction is basically consistent with the plane where the mesh tire is located;

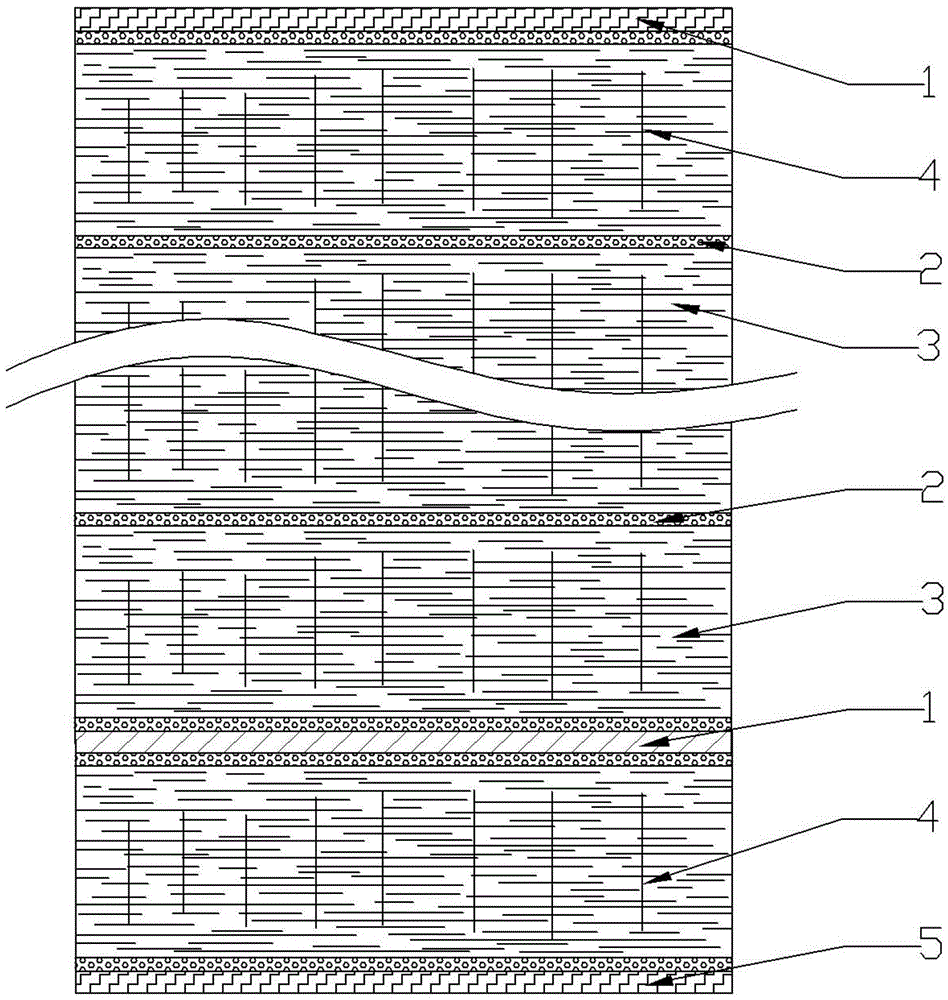

[0056] (2) Use the needle punching method to combine the 8-layer mesh tire into a mesh tire unit, and the needle punching density is 10-20 needles / cm 2 ; The needle punching direction is longitudinal, and the mesh tire unit laying direction is horizontal, that is, the needle punching direction is perpendicular to the plane where the mesh tire unit is located.

[0057] (3) Adopt the mist spraying method to carry out single-sided or double-sided spraying phenolic resin adhesive t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com