Device adopting series-parallel connection combination of multi-family domestic sewage hydrolytic tanks and multiple treatment devices

A treatment device and technology for domestic sewage, which is applied in the field of multi-household domestic sewage hydrolysis tanks and multiple treatment devices in series-parallel combination equipment, can solve problems such as difficulties in pipeline network construction, high financial pressure, and inability to promote, and achieve expansion of treatment capacity, Reduce treatment costs and improve the effect of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

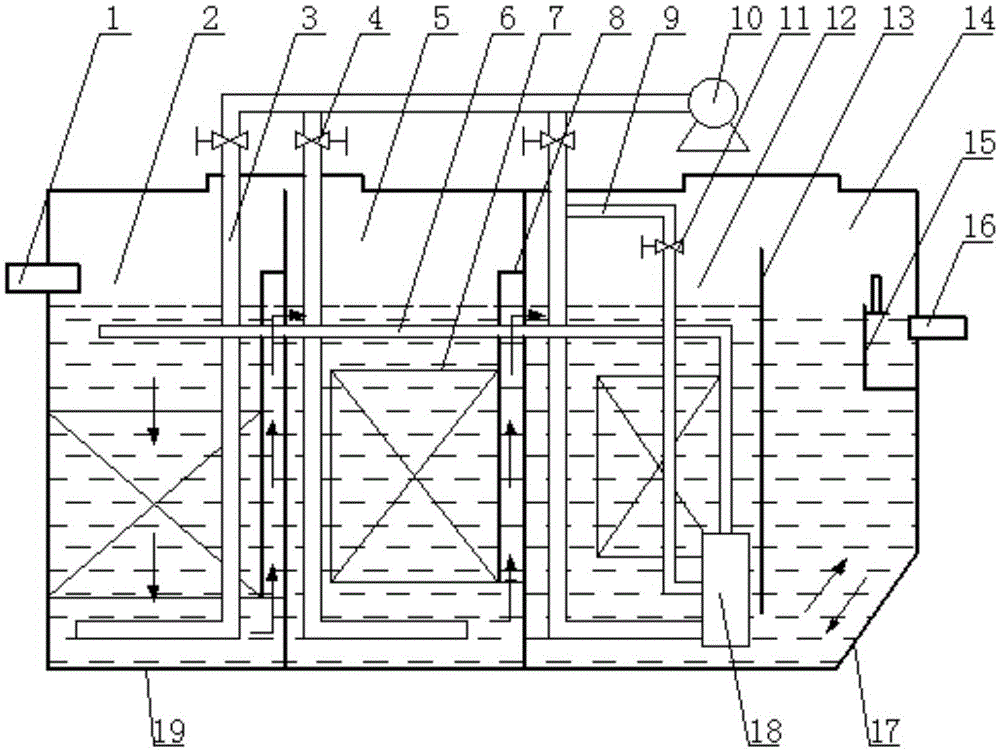

Embodiment 1

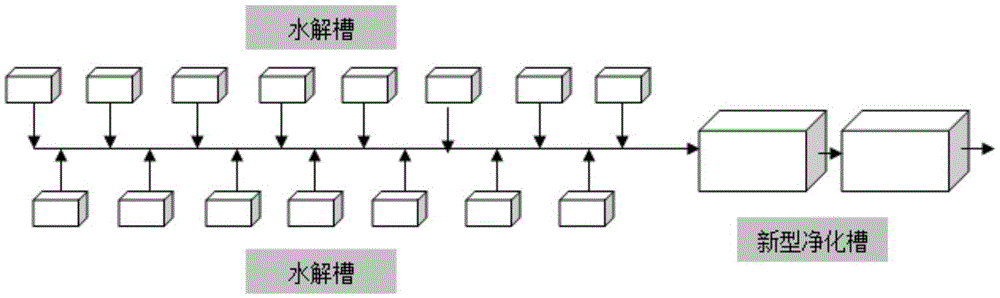

[0054] Joint use of domestic sewage by 15 households: such as image 3 As shown, fifteen hydrolysis tanks (1200X800X1200) and two new-type purification tanks (2100X1500X1700) are connected in series, all aeration is adopted in the first, second and third-level areas. The air pump power of the first new-type purification tank is 200W, and the gas flow rate is 200L / min, the power of the second unit is 150W, the gas flow rate is 150L / min, and the power consumption per ton of water is 0.28 yuan.

[0055] Such as Figure 4 As shown, the water samples in each area from right to left are the water from the hydrolysis tank, the first and third levels of the first new type of purification tank, the first and third levels of the second new type of purification tank, and the effluent from the disinfection tank. From the first-level area of the first new purification tank in the picture, it can be seen that the sewage entering the tank is particularly turbid, with a high concentration...

Embodiment 2

[0057] Combined use of domestic sewage in ten buildings and farmhouses: such as Figure 5 As shown, two hydrolysis tanks (2100X1500X1700) are respectively connected to the domestic sewage of five households from top to bottom, and two new purification tanks (2100X1500X1700) are connected in series, and the sewage treated by the two hydrolysis tanks is concentrated into the new series of purification tanks. The first, second, and third-level areas are all aerated. The air pump power of the first new purification tank is 150W, the gas flow rate is 150L / min, the power of the second one is 120W, the gas flow rate is 120L / min, and the power consumption per ton of water is 0.33 Yuan.

[0058] Changing the amount of aeration can increase the number of processing households. When the new purification tank is fully aerated and the power of the air pump is 200W, the number of processing households can be increased to 20. Under the same conditions, the new purification tanks used in ser...

Embodiment 3

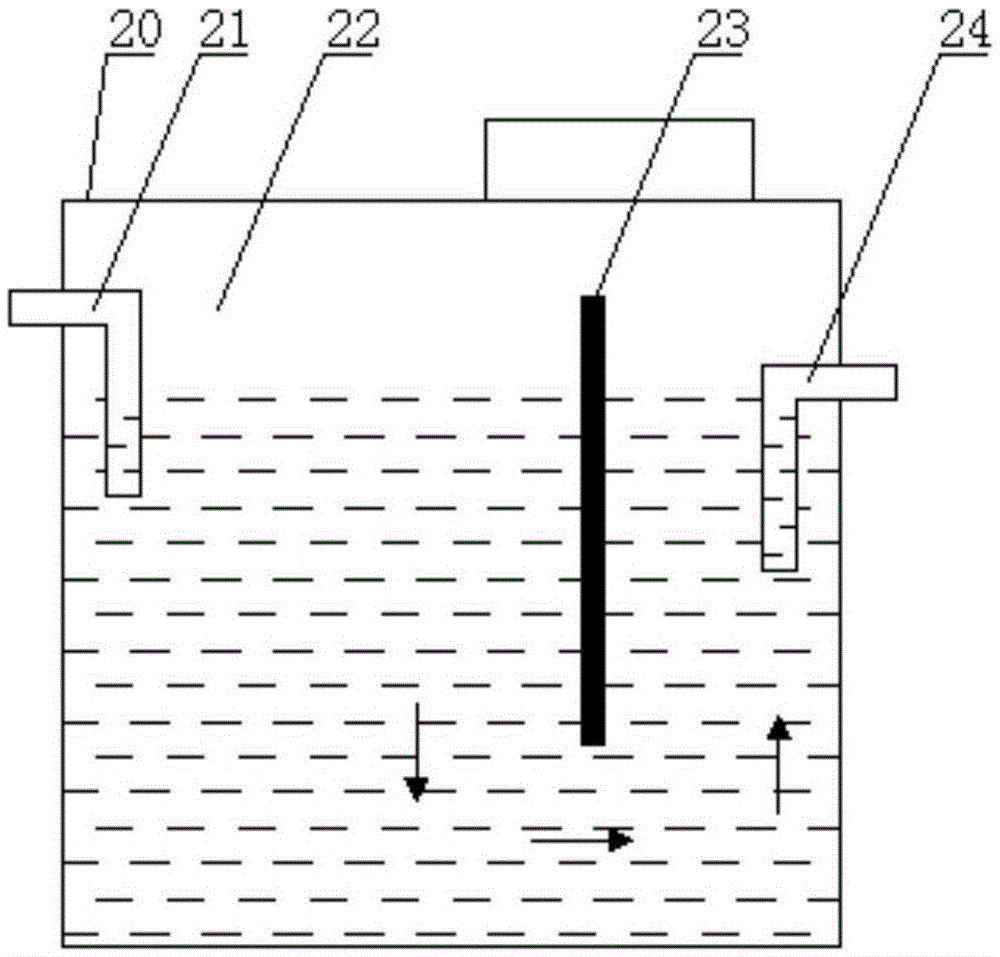

[0061] Such as Figure 7 As shown, the Wucheng branch of Shandong Shuangyi Group Co., Ltd. has 250 employees, a staff canteen, and a daily discharge of domestic sewage of 18 tons. The original three-grid hydrolysis tank of 6 cubic meters will use two sets according to the daily processing capacity. The new purification tank and septic tank series process, as shown in the figure. The first, second, and third-level regional aeration is adopted. The air pump power of the first new purification tank is 200W, the gas flow rate is 200L / min, the power of the second one is 150W, the gas flow rate is 150L / min, and the power consumption per ton of water is 0.24 Yuan.

[0062] Such as Figure 8 As shown, the water samples in each area from right to left are the effluent of the hydrolysis tank, the first and third levels of the first new type of purification tank, the third level of the second new type of purification tank, and the effluent. From the water outlet state of the hydrolysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com