A kind of methanol synthesis separation refrigeration method

A technology for methanol synthesis and refrigeration methods, which is applied in refrigeration and liquefaction, chemical instruments and methods, and preparation of hydroxyl compounds. It can solve the problems of reduced service life of synthesis catalysts, affecting the condensation effect of methanol devices, and the deterioration of methanol separation effects. Avoid corrosion dew point, ensure long-term operation, and reduce the effect of the total amount of wax

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

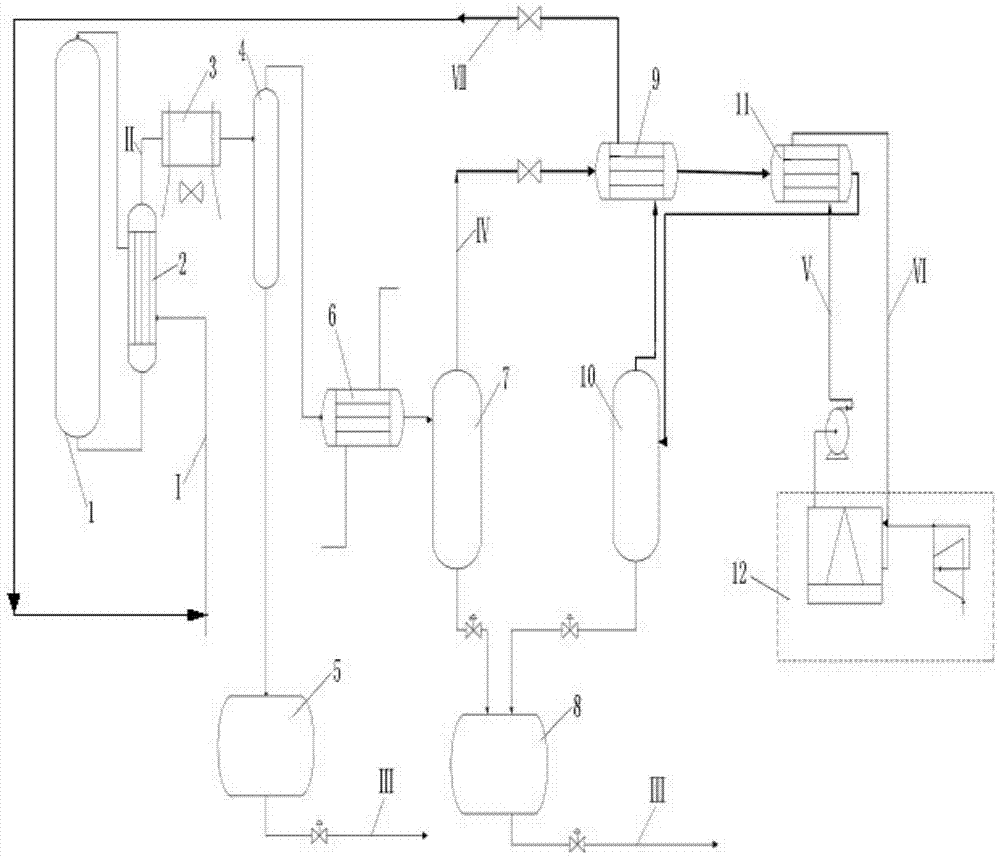

[0061] This embodiment provides a methanol synthesis, separation and refrigeration method using natural gas as a raw material.

[0062] The natural gas used comes from Sebei gas field in Qinghai, the main component is CH 4 ;

[0063] Step (1), the 500,000 m 3 / h The first synthesis gas I is sent to the first heat exchanger 2 to raise the temperature of the first synthesis gas I to 220°C, and the heated first synthesis gas I is sent to the synthesis tower 1 for methanol synthesis reaction;

[0064] Step (2), transporting the reacted gas to the first heat exchanger 2 to cool down to 105° C. to obtain the second synthesis gas II, and then transporting the second synthesis gas II to the air condenser 3 for cooling, The temperature is lowered to 65° C. to obtain the first liquid crude methanol, the liquid wax produced by side reactions and the third synthesis gas;

[0065] In step (3), the obtained first liquid crude methanol, the wax produced by the liquid side reaction and the...

Embodiment 2

[0072] This embodiment provides a methanol synthesis, separation and refrigeration method using natural gas as a raw material.

[0073] The natural gas used comes from Sebei gas field in Qinghai, the main component is CH 4 ;

[0074] Step (1), the 650,000 m 3 / h The first synthesis gas I is sent to the first heat exchanger 2 to raise the temperature of the first synthesis gas I to 220°C, and the heated first synthesis gas I is sent to the synthesis tower 1 for methanol synthesis reaction;

[0075] Step (2), transporting the reacted gas to the first heat exchanger 2 to cool down to 108° C. to obtain the second synthesis gas II, and then transporting the second synthesis gas II to the air condenser 3 for cooling, The temperature is lowered to 67° C. to obtain the first liquid crude methanol, the liquid wax produced by side reactions and the third synthesis gas;

[0076] In step (3), the obtained first liquid crude methanol, the wax produced by the liquid side reaction and the...

Embodiment 3

[0083] This embodiment provides a methanol synthesis, separation and refrigeration method using natural gas as a raw material.

[0084] The natural gas used comes from Sebei gas field in Qinghai, the main component is CH 4 ;

[0085] Step (1), the 750,000 m 3 / h The first synthesis gas I is sent to the first heat exchanger 2 to raise the temperature of the first synthesis gas I to 220°C, and the heated first synthesis gas I is sent to the synthesis tower 1 for methanol synthesis reaction;

[0086] Step (2), transporting the reacted gas to the first heat exchanger 2 to cool down to 115° C. to obtain the second synthesis gas II, and then transporting the second synthesis gas II to the air condenser 3 for cooling, Lower the temperature to 70°C to obtain the first liquid crude methanol, the liquid wax produced by side reactions and the third synthesis gas;

[0087] In step (3), the obtained first liquid crude methanol, the wax produced by the liquid side reaction and the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com