Polycarbonate composite material

A technology of polycarbonate and composite materials, which is applied in the field of polymer material modification, can solve the problems that affect the thermal deformation temperature of products, flow properties, ductility reduction, and sudden drop in molding toughness, etc., and achieve excellent molding stability and color Effects of Stability and Excellent Flexural Modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

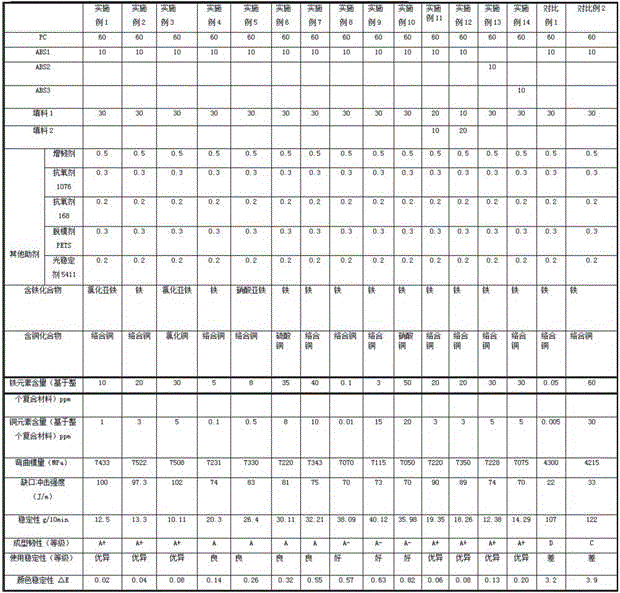

Embodiment 1-14 and comparative example 1-2

[0059] Embodiment 1-14 and comparative example 1-2: the preparation of polycarbonate composite material

[0060] According to the formula shown in Table 1, polycarbonate, ABS resin, copper-containing compound, iron-containing elemental substance, iron-containing compound, and filler are blended in a high-mixer to obtain a pretreated resin matrix; the pretreated resin matrix After weighing with other additives according to the proportion, blending is completed by a high-speed mixer or a mixer, the extrusion temperature is 240 ° C, cooled by water, and granulated to obtain a polycarbonate composite material of columnar particles. The ratio of each component and performance test results are shown in Table 1.

[0061] Various performance evaluation methods:

[0062] (1) Flexural modulus:

[0063] The polycarbonate composite material was injection molded at an injection temperature of 260°C, the mold temperature was 100°C, and the test piece with a sample size of 12.6mm*3.2mm and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com