Preparation method of polyolefin nanometer electric composite dielectric material SEM analysis sample

A composite medium and analysis sample technology, which is used in the preparation of test samples, material analysis using wave/particle radiation, and analysis of materials, etc., can solve the problem that the sample is not flat enough, the surface information is real, and the polyolefin cannot be distinguished. Nanoparticles and other problems to achieve the effect of eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific Embodiment 1: In this embodiment, polyolefin nanoelectric composite dielectric materials are prepared from polypropylene particles and nano-silica with a particle size of 50 nm; the specific method is as follows: polypropylene particles and nano-silica with a particle size of 50 nm Place them in evaporating dishes respectively (the evaporating dish containing polyolefin particles is not covered, and the evaporating dish containing nanomaterials is covered), the temperature of the drying oven is set at 50°C, and the drying time is 24h; Polyethylene particles and nano-silica were mixed at a mass ratio of 100:1, the heating temperature of the torque rheometer was set at 190°C, and the mixing time was 20 minutes; a polyolefin nanoelectric composite dielectric material was obtained.

[0024] In the present embodiment, the preparation method of polyolefin nanoelectric composite dielectric material SEM analysis sample is completed by the following steps:

[0025] Step...

specific Embodiment approach 2

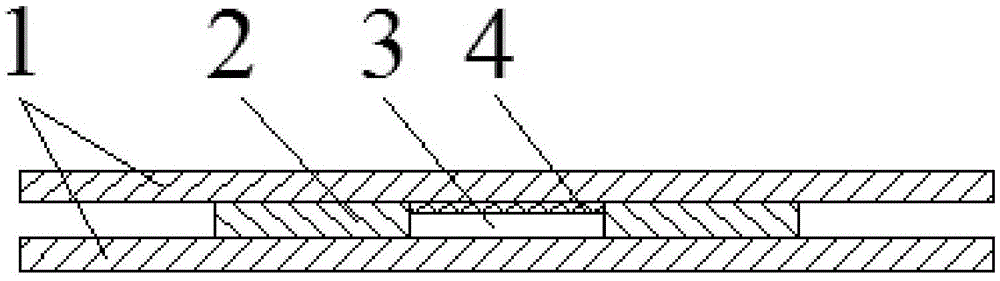

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step 2, a metal mesh with a mesh number of 100 is placed on the sheet sample (see image 3 ). Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com