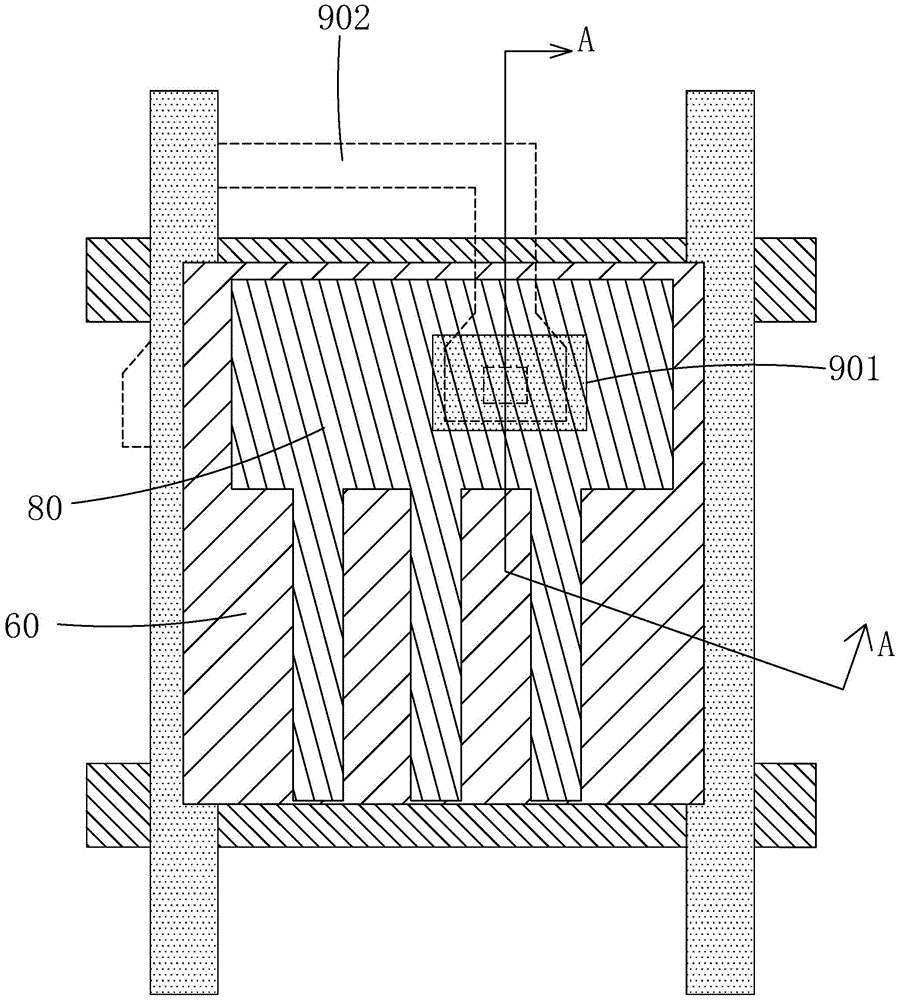

TFT (thin film transistor) array substrate

A technology of array substrates and substrate substrates, which is applied in the directions of optics, instruments, electrical components, etc., can solve the problems of difficult changes and the inability to increase the capacity of storage capacitors, and achieve the goals of improving crosstalk, improving display quality, and increasing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

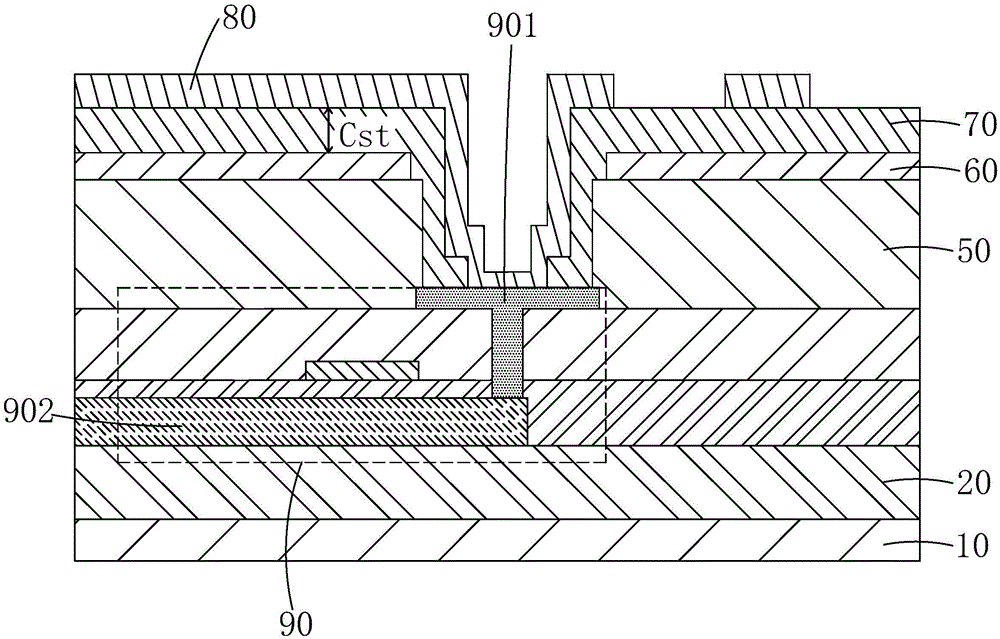

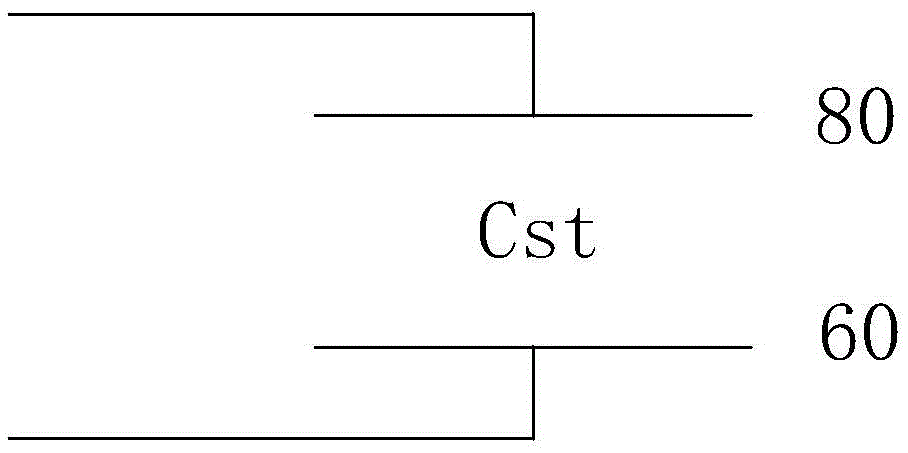

[0039] see Figure 4 and Figure 6 , in order to further increase the storage capacitance, in the second embodiment of the TFT array substrate of the present invention, the thickness of the flat layer 500 located in the area where the drain electrode 420 overlaps with the horizontal projection of part of the common electrode 600 is smaller than that located in the The thickness of the planar layer 500 outside the region where the horizontal projection of the drain electrode 420 overlaps with part of the common electrode 600 can specifically be fabricated with different thicknesses of the planar layer 500 by exposing with a half-tone mask. Compared with the first embodiment, the second embodiment reduces the distance between one electrode plate (common electrode 600) and the other electrode plate (drain 420) of the first capacitor Cst1, thereby further increasing the distance between the first capacitor Cst1 A capacity of the capacitor Cst1. Preferably, the thickness of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com