Method and arrangement for determining leakage inductances of double fed induction generator

A double-fed induction and leakage inductance technology, applied in the field of leakage inductance, can solve problems such as poor control performance of double-fed induction generators, achieve cost-effectiveness, and improve response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The application of the embodiments herein is not limited to any particular doubly-fed induction generator (DFIG) system, but it can be applied to various DFIG systems. Furthermore, the practice of the invention is not limited to, for example, any particular fundamental frequency or any particular voltage level.

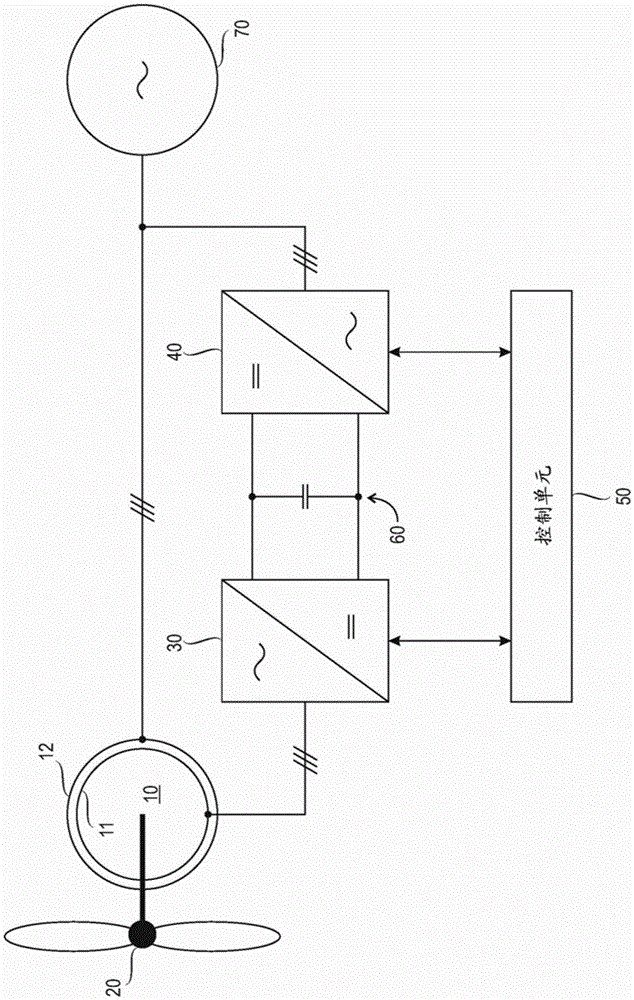

[0014] figure 1 A simplified block diagram of a doubly-fed induction generator system according to an embodiment is shown. The figure shows only the components necessary for understanding the invention. An exemplary doubly-fed induction generator system includes a doubly-fed induction generator 10 having a rotor 11 and a stator 12 . In this example, DFIG10 is a three-phase DFIG. The rotor 11 of the DFIG 10 may be mechanically connected to a turbine 20 , such as a wind turbine, for driving the generator 10 . The stator 12 of the DFIG 10 may be electrically connected to a three-phase alternating current (AC) network 70 for providing the AC network 70 with ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com