Sterile microstructure body and preparation method thereof

A technology of microstructures and microneedles, which is applied in the fields of biomedicine and medical cosmetology, can solve the problems of high manufacturing cost, inability to guarantee the hardness and use effect of microneedles, complicated process, etc., and achieve the effect of excellent hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

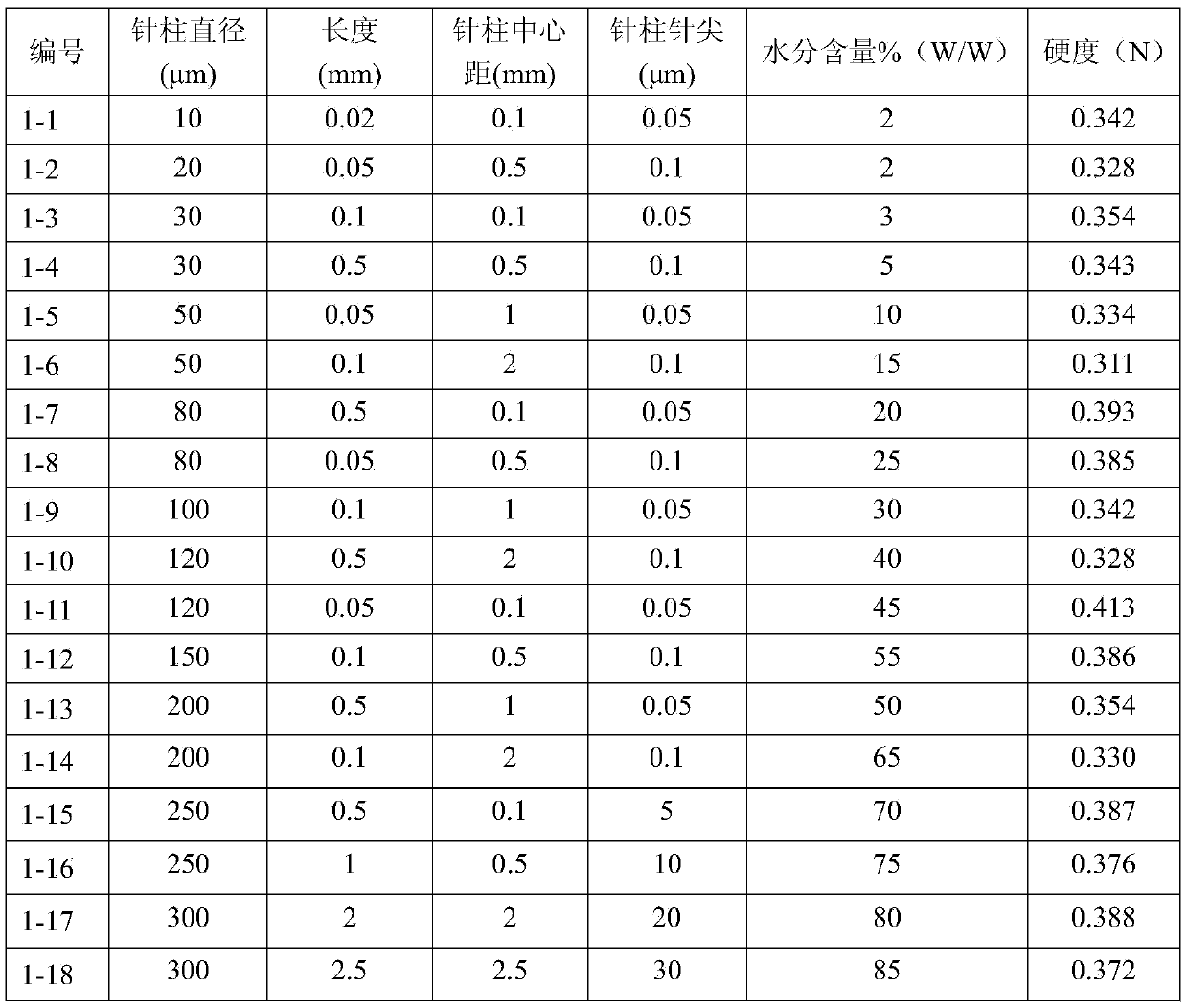

[0023] Embodiment 1: Performance comparison of microstructures

[0024] In this experiment, the performance of several microstructures was compared. The biodegradable material of the substrate and the microneedle column is both dextrin, and the pH of the microstructure is 7.1. Other performance parameters are shown in Table 1.

[0025] Hardness test method: Insert the tip of the microstructure into a rubber with a thickness of 2.5mm at an insertion speed of 6mm / s, and measure the maximum force when inserting the rubber, which is the hardness of the microstructure. The greater the insertion force, the higher the hardness.

[0026] Table 1.

[0027]

Embodiment 2

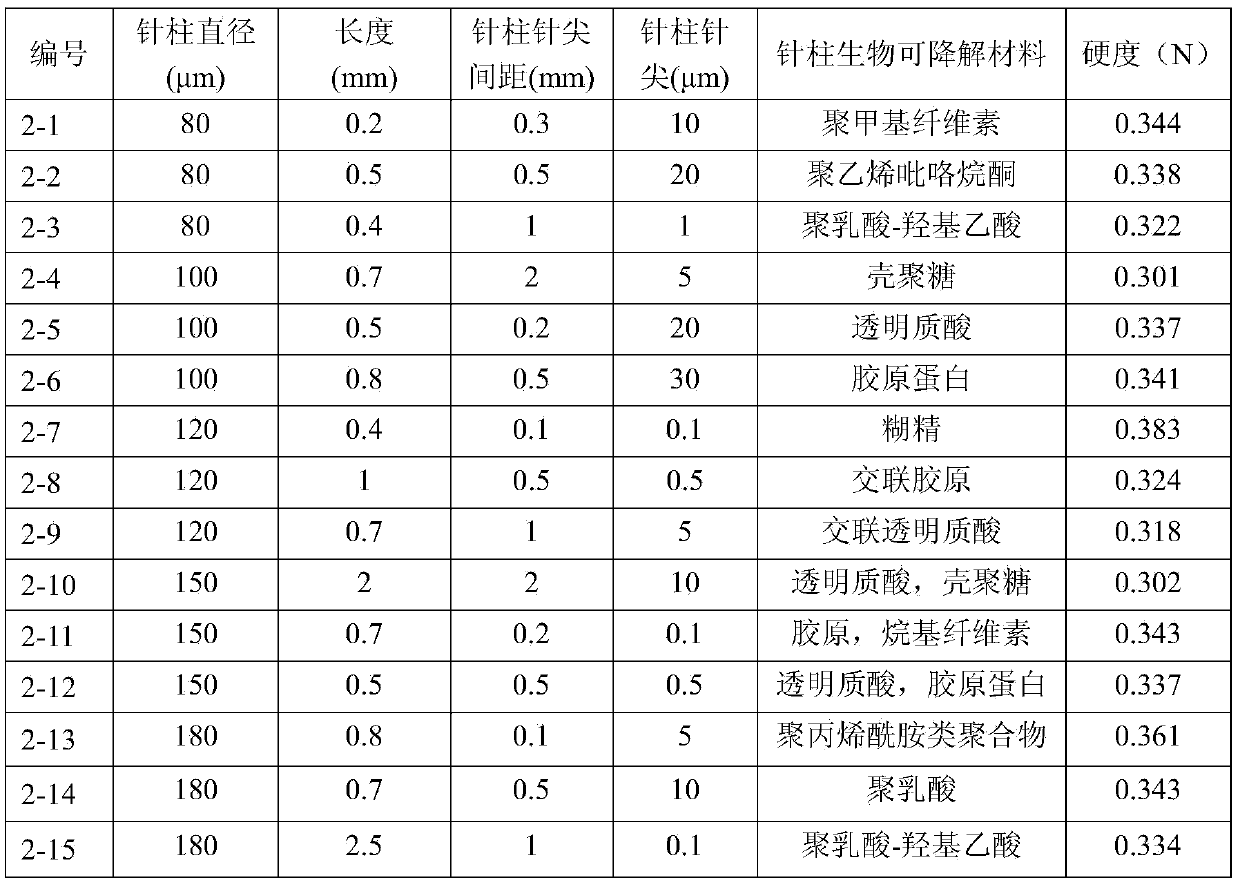

[0028] Embodiment 2: Performance comparison of microstructures

[0029] In this experiment, the properties of several microstructures were compared. The substrate was carboxymethyl cellulose, the water content of the needle column was 25.2% (W / W), and the pH of the microstructure was 7.2. Other performance parameters are shown in Table 2. The method of hardness test is the same as that of Example 1.

[0030] Table 2.

[0031]

Embodiment 3

[0032] Example 3: Performance comparison of microstructures containing additives

[0033] In this experiment, the properties of several microstructures were compared. The substrate is silk protein, the biodegradable material is polyacrylamide polymer, and the pH of the microstructure is 7.0. Other performance parameters are shown in Table 3. The method of hardness test is the same as that of Example 1.

[0034] table 3.

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com