Heat treatment reaction tail gas purification and recovery technology and system

A heat treatment reaction and tail gas purification technology, applied in gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problems of increasing greenhouse gas carbon dioxide emissions, losing linear alkanes and aromatics, wasting nitrogen, etc., to achieve the elimination of safety hidden dangers, reduce emissions, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

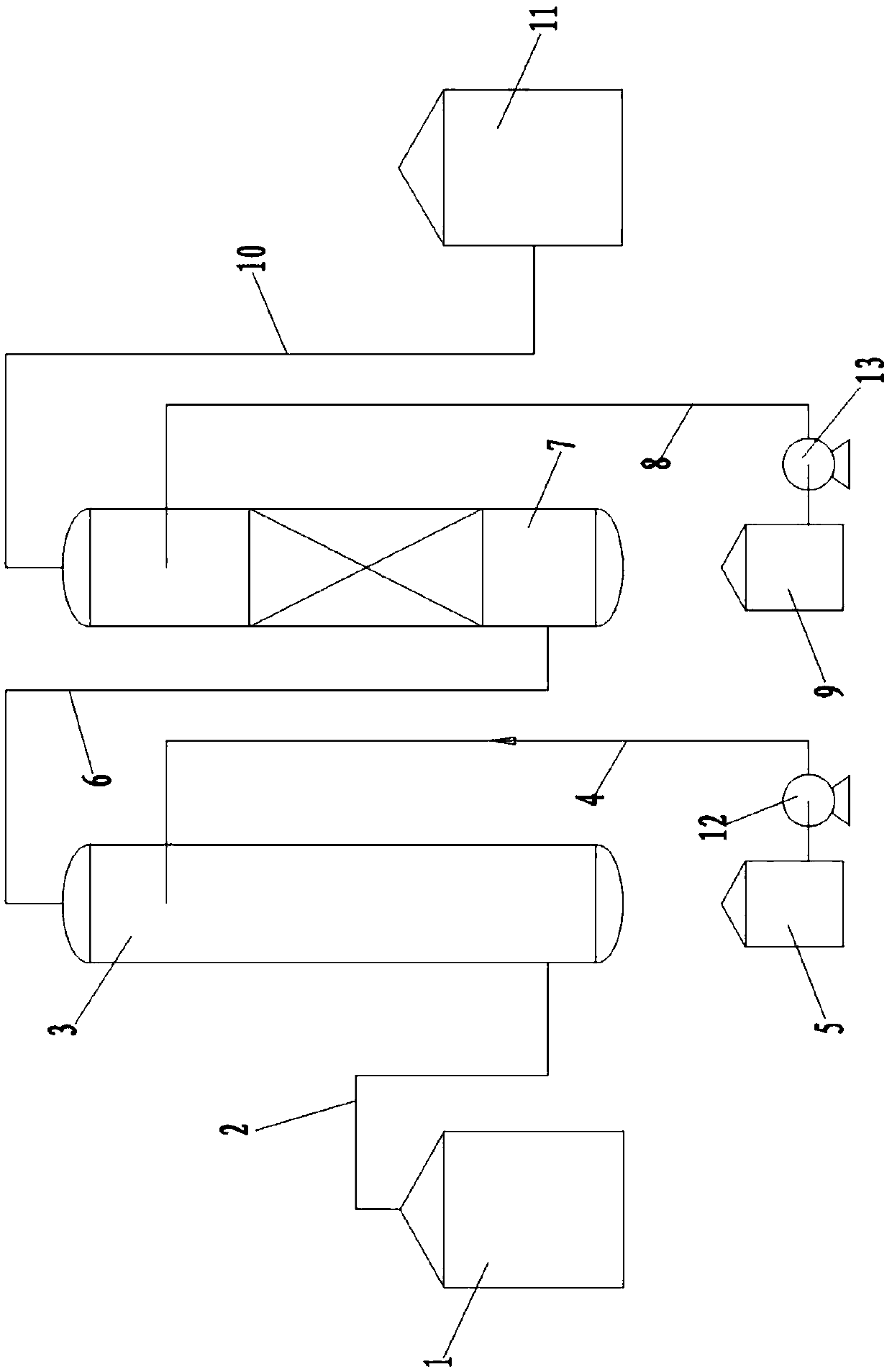

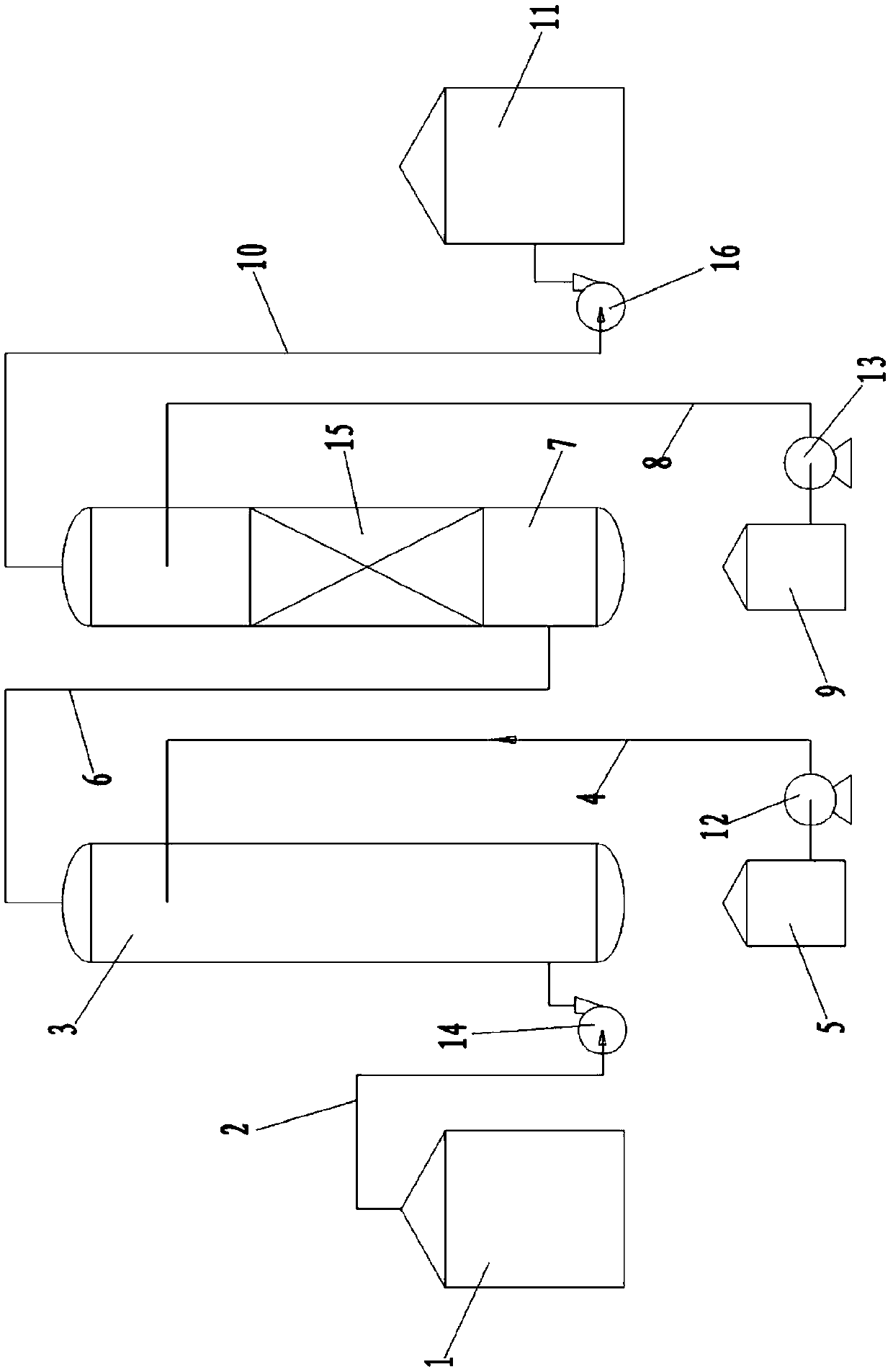

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

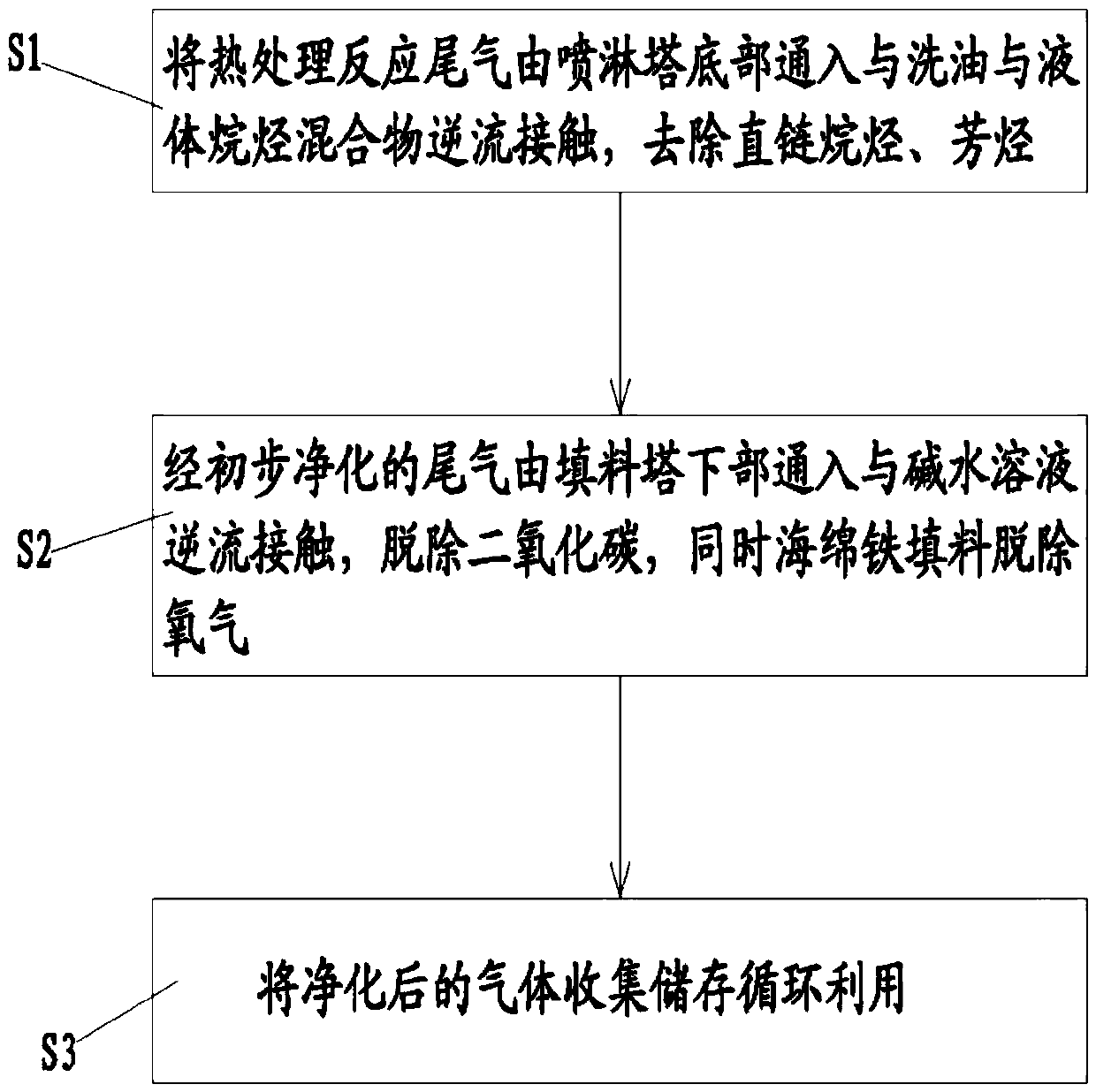

[0024] Such as figure 1 Shown, the flow chart of the embodiment of heat treatment reaction tail gas purification and recovery process of the present invention, it comprises the following steps:

[0025] S1. Pass the collected heat treatment reaction tail gas from the bottom of the spray tower into countercurrent contact with the wash oil and liquid alkane mixture to remove linear alkanes and aromatics; the heat treatment reaction tail gas is passed from the bottom of the spray tower to the upper part of the spray tower inner cavity The washed oil and the liquid alkane mixture are contacted in countercurrent, and the mixture of the washed oil and the liquid alkane is used as the absorbent through similar miscibility and gas-liquid mass transfer and heat transfer. Well, the washing oil has an aromatic structure, a mixture of aromatics, and has good compatibility with ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com