Low-temperature diesel exhaust reducing agent and preparation method thereof

A reducing agent and low-temperature technology, which is applied in the chemical industry, can solve the problems of affecting the overall stability of the solution, uneven dissolution, and the detection amount is easy to exceed the standard, so as to achieve high use and promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A preparation method of a low-temperature diesel exhaust reducing agent: (1) adding high-purity urea into a round-bottomed flask added with high-purity water, sealing it with a ground plug, heating to 35°C to 40°C, stirring until the urea is completely dissolved, The solution is transparent;

[0049] (2) Cool the solution obtained in step (1) to room temperature, add a small molecule liquid amide substance, seal it with a ground plug, and stir until the solution is completely mixed and uniform.

[0050] (3) Add small molecule alcohols to the solution obtained in step (2), seal it with a ground plug, and stir until the solution is completely mixed and uniform.

[0051] (4) Pressure filter the solution obtained in step (3) with a filter element with a filtration accuracy of 0.8pm to obtain the low-temperature tail gas catalytic reducer product of the present invention.

[0052] (5) Preparation of pilot test and commercial products: scale up all raw materials in proportio...

Embodiment 1

[0071] (1) Add 7.2822g of high-purity urea into a round-bottomed flask to which 15.1660g of high-purity water has been added, seal it with a ground plug, heat it in a water bath to 40°C, and stir magnetically until the urea is completely dissolved and the solution is transparent;

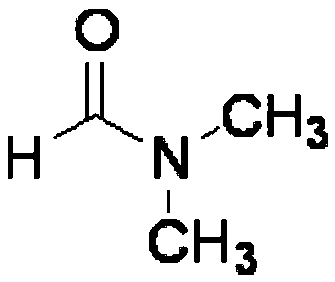

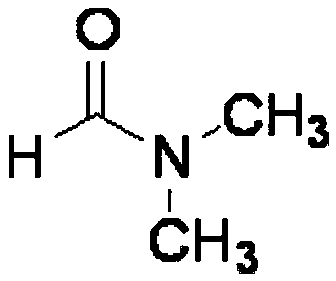

[0072] (2) Cool the solution obtained in step (1) to room temperature, add 3.7440 g of N,N-dimethylformamide, seal it with a ground plug, and stir magnetically until the solution is completely mixed and uniform.

[0073] (3) Add 0.7859 g of methanol to the solution obtained in step (2), seal it with a ground plug, and stir magnetically until the solution is completely mixed and uniform.

[0074] (4) Pressure filter the solution obtained in step (3) with a filter element with a filtration accuracy of 0.8pm to obtain the low-temperature tail gas catalytic reducer product of the present invention.

[0075] (5) After measurement, the freezing point of the mixture solution is -18°C, the surface tension i...

Embodiment 2

[0077] (1) Add 7.2176g of high-purity urea into a round-bottomed flask to which 15.1024g of high-purity water has been added, seal it with a ground plug, heat in a water bath to 40°C, and stir magnetically until the urea is completely dissolved and the solution is transparent;

[0078] (2) Cool the solution obtained in step (1) to room temperature, add 3.6189 g of N,N-dimethylformamide, seal it with a ground plug, and stir magnetically until the solution is completely mixed and uniform.

[0079] (3) Add 1.6670 g of methanol to the solution obtained in step (2), seal it with a ground plug, and stir magnetically until the solution is completely mixed and uniform.

[0080] (4) Pressure filter the solution obtained in step (3) with a filter element with a filtration accuracy of 0.8pm to obtain the low-temperature tail gas catalytic reducer product of the present invention.

[0081] (5) After measurement, the solidification point of the mixture solution is -20°C, the surface tensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com