A control method and control device for internal holes in a weld during laser welding

An internal hole, laser welding technology, used in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of difficult implementation, narrow process window, concave weld seam, etc., and achieve simple and easy implementation, low cost and convenient effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

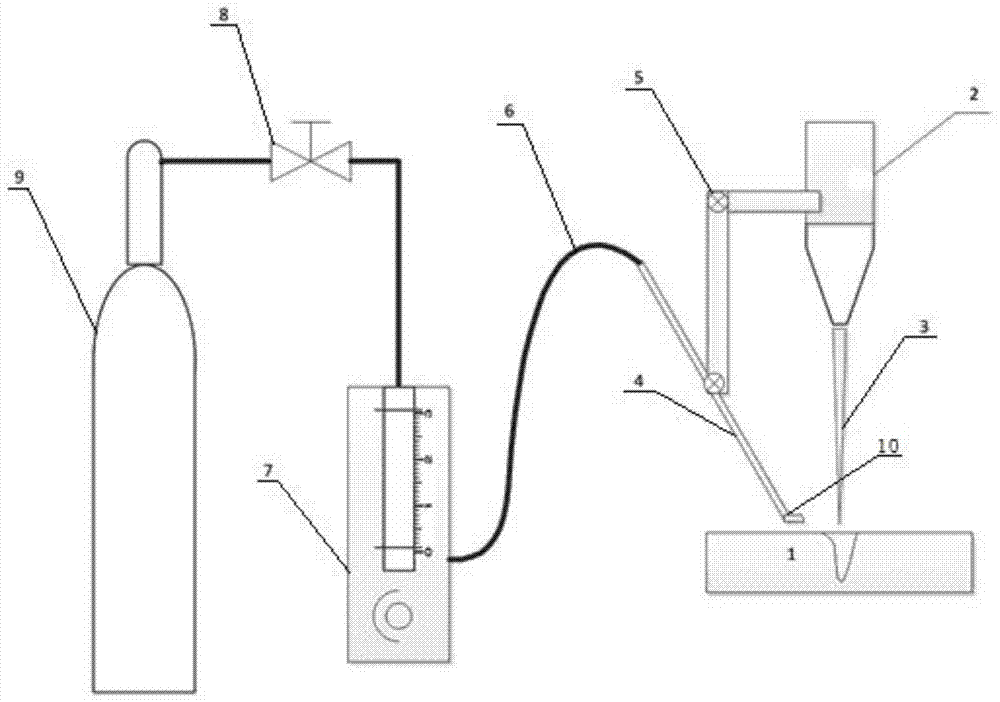

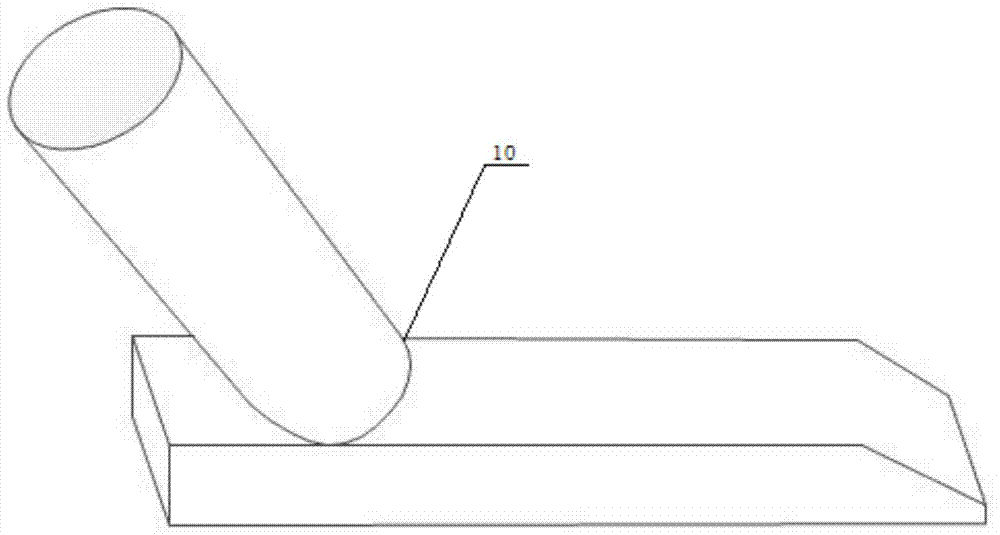

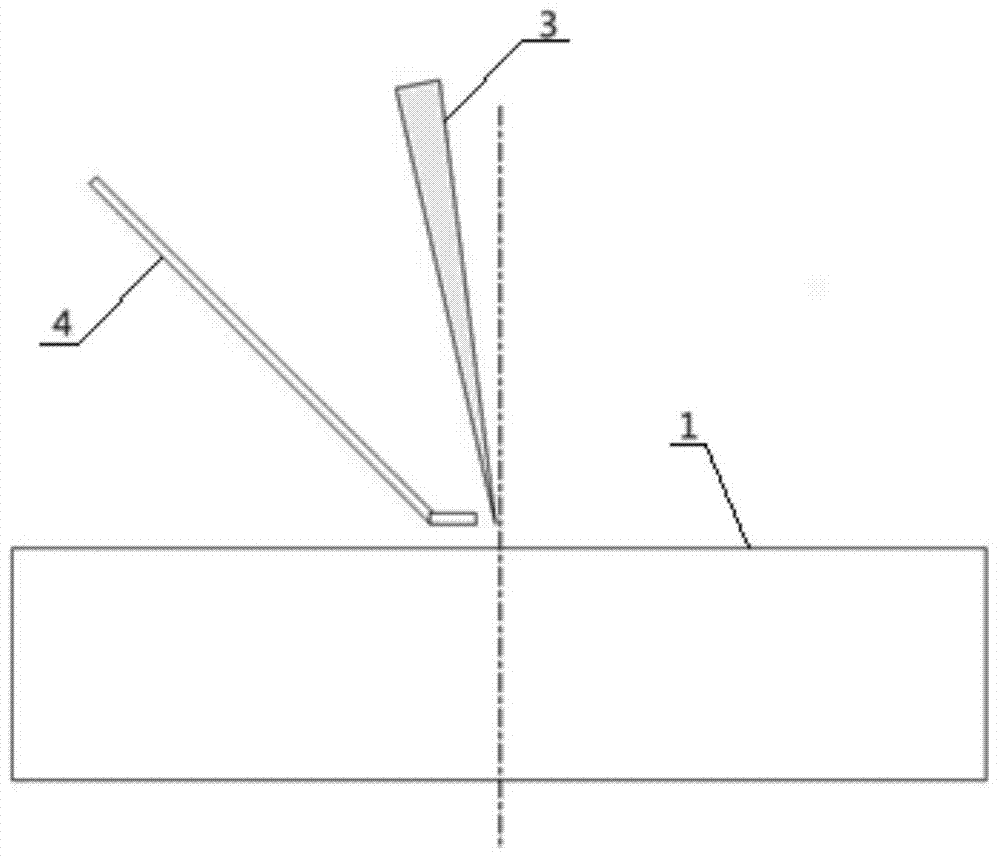

[0025] When the laser head 2 of the laser device emits laser light 3 to carry out deep penetration welding on the workpiece 1, the air blowing device is used to blow out the air flow above the molten pool 12 to form a local negative pressure above the molten pool 12 and the keyhole 11, thereby The steam in the keyhole 11 is blown away to ensure the smoothness of the keyhole 11, so that the gas generated during the welding process escapes from the inside of the molten pool 12 to avoid forming holes. The flat blowing nozzle 10 together, the airflow blown out by the flat blowing nozzle 10 is in the horizontal direction and the flow velocity is 3000m / min, the vertical distance between the airflow outlet of the flat blowing nozzle 10 and the workpiece 1 is 2mm, and it is connected with the laser The horizontal spacing of the laser beams emitted by the head 2 is 3mm, and ΔP=1.5KPa.

Embodiment 2

[0027]When the laser head 2 of the laser device emits laser light 3 to carry out deep penetration welding on the workpiece 1, the air blowing device is used to blow out the air flow above the molten pool 12 to form a local negative pressure above the molten pool 12 and the keyhole 11, thereby The steam in the keyhole 11 is blown away to ensure the smoothness of the keyhole 11, so that the gas generated during the welding process escapes from the inside of the molten pool 12 to avoid forming holes. The flat blowing nozzle 10 together, the airflow blown out by the flat blowing nozzle 10 is in the horizontal direction and the flow velocity is 6000m / min, the vertical distance between the airflow outlet of the flat blowing nozzle 10 and the workpiece 1 is 5mm, and it is connected with the laser The horizontal spacing of the laser beams emitted by the head 2 is 1mm, and ΔP=6KPa.

Embodiment 3

[0029] When the laser head 2 of the laser device emits laser light 3 to carry out deep penetration welding on the workpiece 1, the air blowing device is used to blow out the airflow above the molten pool 12 to form a local negative pressure above the molten pool 12 and the keyhole 11, thereby The steam in the keyhole 11 is blown away to ensure the smoothness of the keyhole 11, so that the gas generated during the welding process escapes from the inside of the molten pool 12 and avoids forming holes. The flat blowing nozzle 10 together, the airflow blown out by the flat blowing nozzle 10 is in the horizontal direction and the flow velocity is 5000m / min, the vertical distance between the airflow outlet of the flat blowing nozzle 10 and the workpiece 1 is 4mm, and it is connected with the laser The horizontal spacing of the laser beams emitted by the head 2 is 4mm, and ΔP=4.2KPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com