Efficient sewage dephosphorizing flocculating agent and preparation method thereof

A flocculant and sewage technology, which is applied in the field of high-efficiency sewage phosphorus removal flocculants and its preparation, can solve the problems that biological phosphorus removal technology is difficult to meet the requirements of phosphorus removal indicators, and achieve the effect of simple preparation method and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

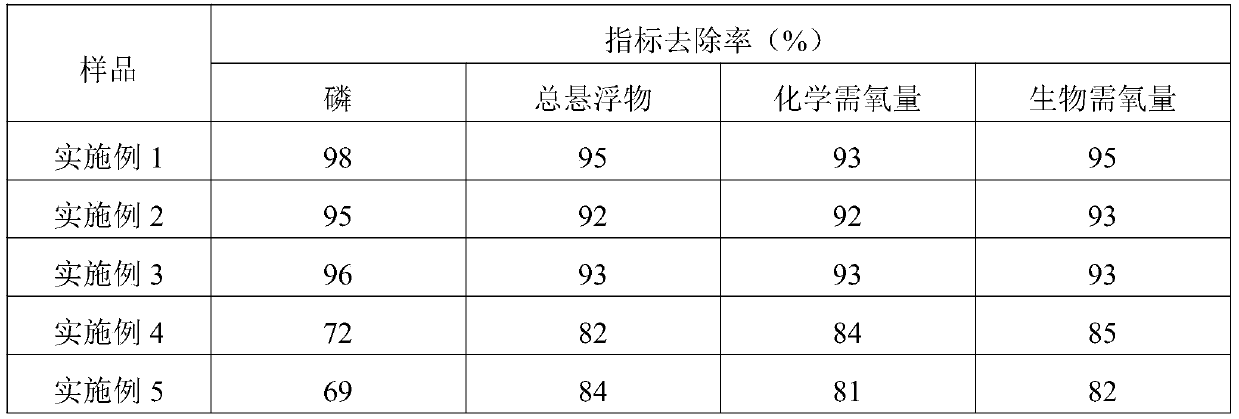

Examples

Embodiment 1

[0020] Embodiment 1: Preparation of phosphorus removal flocculant

[0021] Raw material ratio:

[0022] Water, 35 parts; Potassium perchlorate, 6 parts; Sodium silicate, 25 parts; Ferrous sulfate, 30 parts; The mixture of aluminum sulfate and magnesium sulfate, 40 parts; Wherein, the weight ratio of aluminum sulfate and magnesium sulfate is 4:1 .

[0023] Preparation:

[0024] (1) Prepare metal salt mixed solution: under normal temperature and pressure, ferrous sulfate, aluminum sulfate and magnesium sulfate are mixed with water, stirred and mixed to form metal salt mixed solution;

[0025] (2) Adjust the pH value of the metal salt mixed solution: in the prepared metal salt mixed solution, slowly add concentrated sulfuric acid while stirring, so that all metal sulfates are completely dissolved, and adjust its pH value to 1.5;

[0026] (3) metal oxidation reaction: under normal temperature and pressure, slowly add potassium perchlorate to carry out oxidation reaction while s...

Embodiment 2

[0028] Embodiment 2: Preparation of phosphorus removal flocculant

[0029] Raw material ratio:

[0030] Water, 30 parts; Potassium perchlorate, 4 parts; Sodium silicate, 20 parts; Ferrous sulfate, 25 parts; The mixture of aluminum sulfate and magnesium sulfate, 35 parts; Wherein, the weight ratio of aluminum sulfate and magnesium sulfate is 3:1 .

[0031] Preparation:

[0032] (1) Prepare metal salt mixed solution: under normal temperature and pressure, ferrous sulfate, aluminum sulfate and magnesium sulfate are mixed with water, stirred and mixed to form metal salt mixed solution;

[0033] (2) Adjust the pH value of the metal salt mixed solution: in the prepared metal salt mixed solution, slowly add concentrated sulfuric acid while stirring, so that all metal sulfates are completely dissolved, and adjust its pH value to 1;

[0034] (3) metal oxidation reaction: under normal temperature and pressure, slowly add potassium perchlorate to carry out oxidation reaction while sti...

Embodiment 3

[0036] Embodiment 3: Preparation of phosphorus removal flocculant

[0037] Raw material ratio:

[0038] Water, 40 parts; Potassium perchlorate, 8 parts; Sodium silicate, 30 parts; Ferrous sulfate, 35 parts; The mixture of aluminum sulfate and magnesium sulfate, 45 parts; Wherein, the weight ratio of aluminum sulfate and magnesium sulfate is 5:1 .

[0039] Preparation:

[0040] (1) Prepare metal salt mixed solution: under normal temperature and pressure, ferrous sulfate, aluminum sulfate and magnesium sulfate are mixed with water, stirred and mixed to form metal salt mixed solution;

[0041] (2) Adjust the pH value of the metal salt mixed solution: in the prepared metal salt mixed solution, slowly add concentrated sulfuric acid while stirring, so that all metal sulfates are completely dissolved, and adjust its pH value to 2;

[0042] (3) metal oxidation reaction: under normal temperature and pressure, slowly add potassium perchlorate to carry out oxidation reaction while sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com