A kind of ph adjustment method of anaerobic fermentation liquid

A technology of anaerobic fermentation broth and adjustment method, which is applied in the field of pH adjustment of anaerobic fermentation broth, can solve the problems of imperfect reuse technology, inability to meet diversification, etc., so as to reduce the cost of separate treatment, eliminate safety hazards, and reduce procurement. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

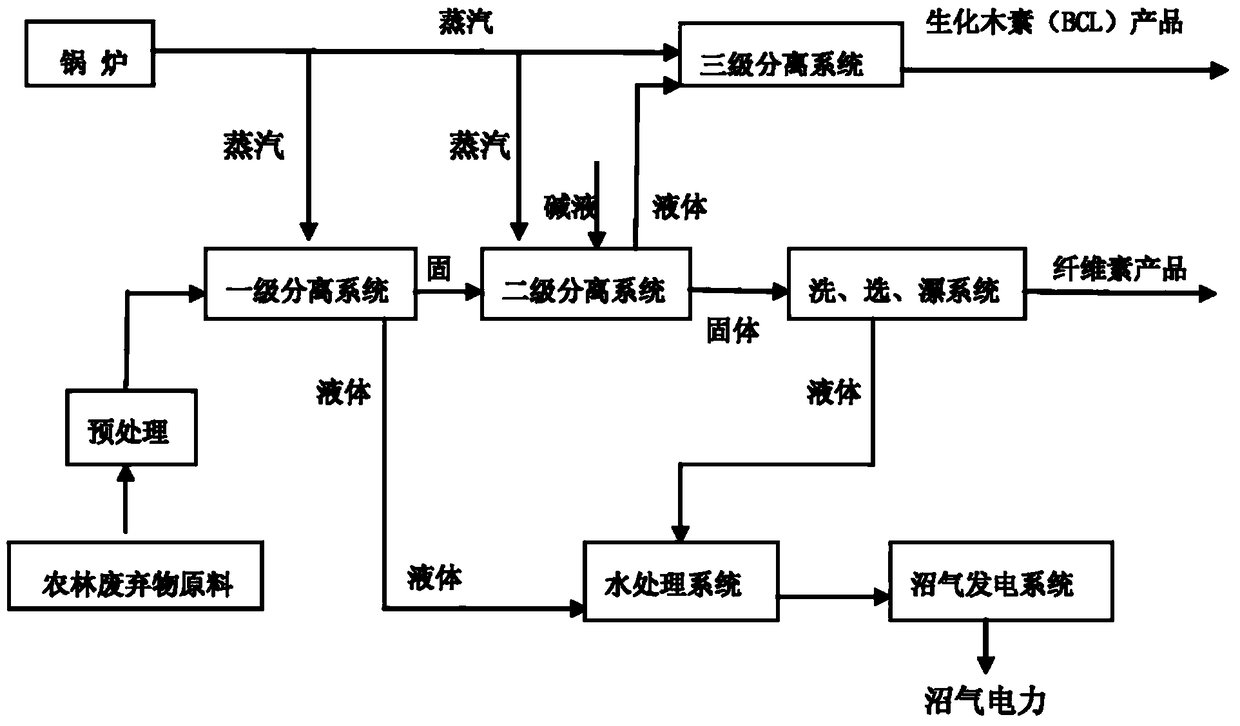

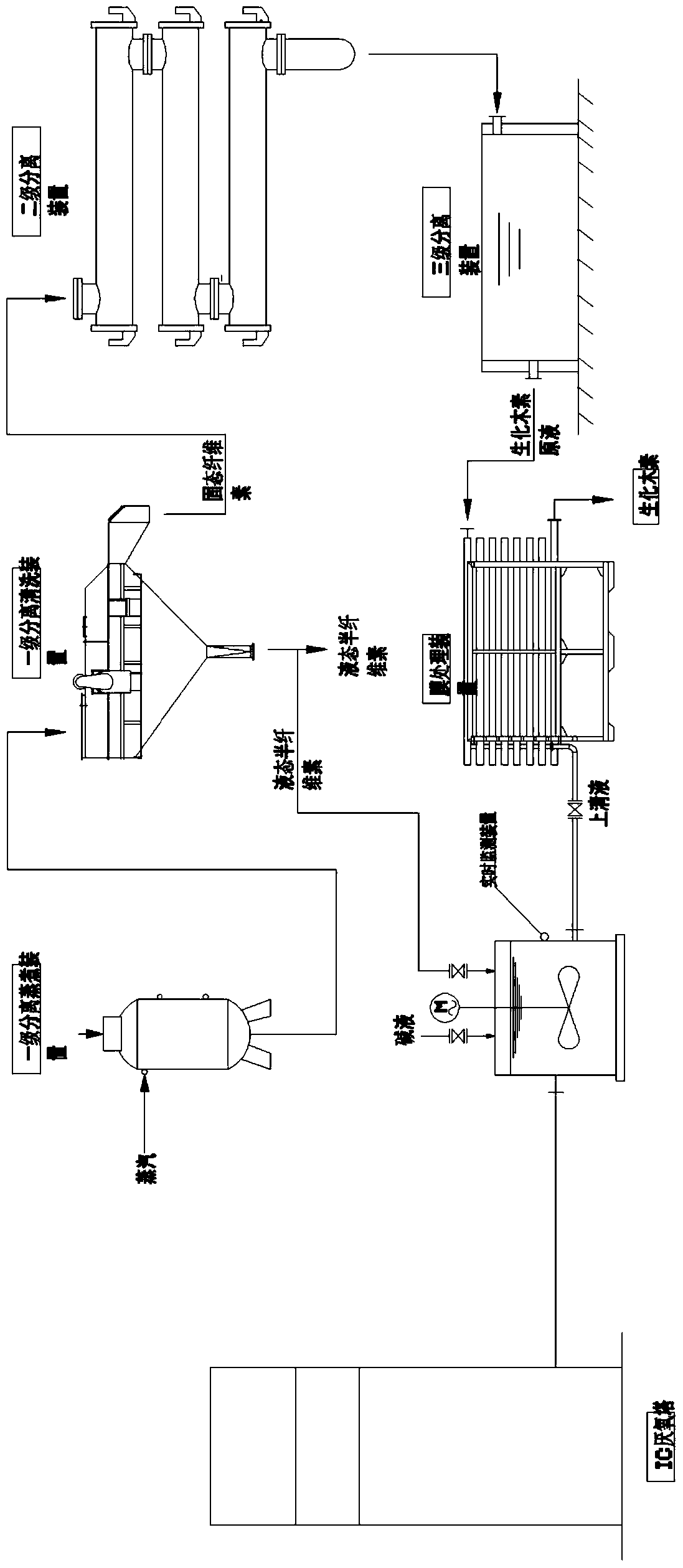

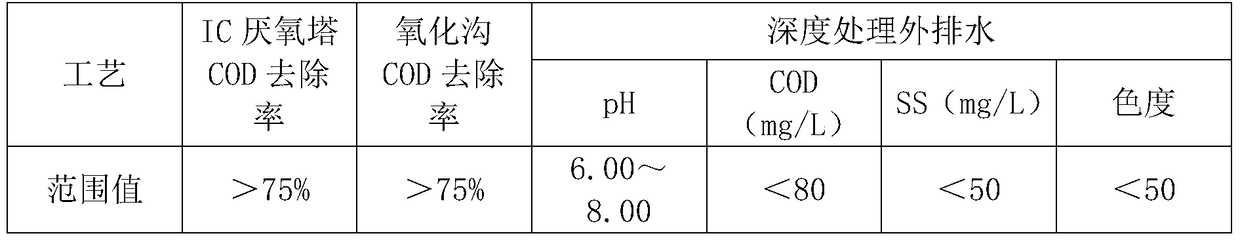

Method used

Image

Examples

Embodiment

[0037] 1. Clear liquid storage tank: the storage tank is a cuboid stainless steel box type with a volume of 12m 3 .

[0038] 2. When the clear liquid comes to the water treatment, it first enters the storage tank, and then by adjusting the outlet valve of the storage tank, the flow rate is controlled so that the pH of the circulating pool can be kept within the range of 6.8 to 7.5.

[0039] 3. Various indicators of the clear liquid: temperature ≤ 45°C, pH value 12-12.5, COD (chemical oxygen demand) content ≤ 15000mg / L, SS (suspended solids) content ≤ 300mg / L.

[0040] 4. Various indicators of the hemicellulose liquid entering the circulating pool: temperature 30°C-37°C, pH value 5.0-7.5, COD (chemical oxygen demand) content ≤ 8000mg / L, SS (suspended solids) content ≤ 500mg / L .

[0041] 5. Various indicators of the hemicellulose liquid in the circulating pool: temperature 30°C-37°C, pH value 6.8-7.5, COD (chemical oxygen demand) content ≤ 8000mg / L, SS (suspended solids) conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com