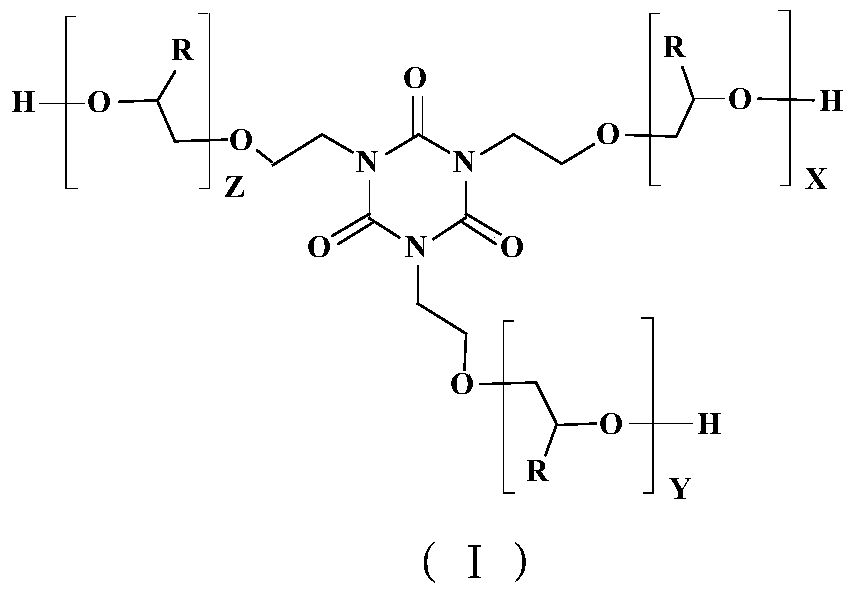

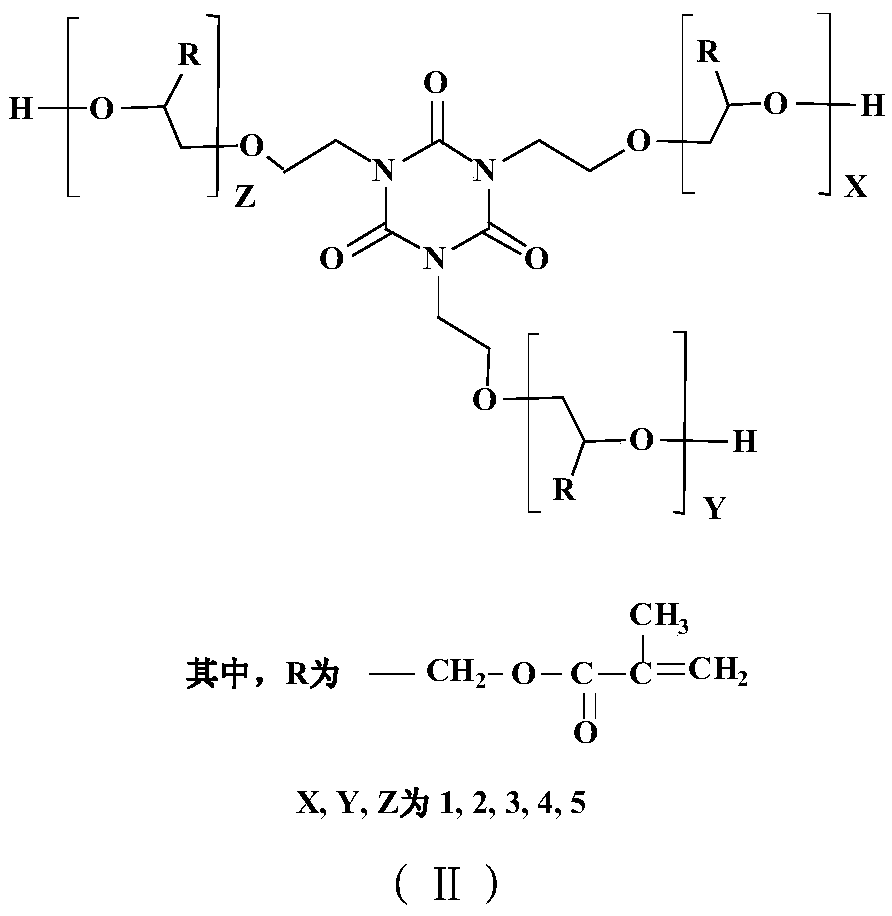

Pluridentate macromolecular bonding agent and preparation method thereof

A technology of macromolecules and bonding agents, which is applied in the field of multi-dentate structure macromolecular bonding agents and the preparation thereof, can solve the problems of complicated operation, many synthesis steps, insignificant improvement of tensile strength and the like, and achieves a simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

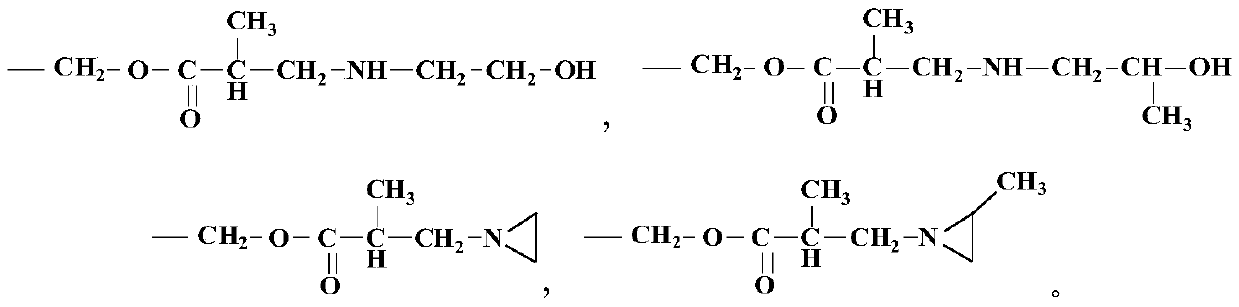

Method used

Image

Examples

Embodiment 1

[0023] Add 20mL of toluene to a 100mL three-neck flask, add 2.5g of tris(2-hydroxyethyl)isocyanurate, 12.2g of glycidyl methacrylate, stir, Fe-Zn double metal cyanide complex The addition amount is 680ppm, the temperature is raised to 135°C, and the reaction is carried out at constant temperature for 4 hours. The solvent and unreacted raw materials were distilled off under reduced pressure to obtain a light yellow viscous liquid with a yield of 98.3%. Product characterization data are as follows: IR (cm-1): 3448, 2959, 2879, 1718, 1693, 1637, 1460, 1169; 1HNMR: 1.949 (-CH3); 3.695, 4.187, 4.320 (-CH2); 5.592, 6.113 ( -C=CH2); 7.287 (CDCl3)

[0024] Take 15g of the above intermediate, dissolve it in 20mL of chloroform, add 6.4g of isopropanolamine, stir, and react at 25°C for 6h. The solvent was distilled off under reduced pressure to obtain 21 g of light yellow viscous liquid, designated as J-01.

[0025] Product Characterization IR (cm-1): 3375, 2968, 2931, 2880, 1726, 169...

Embodiment 2

[0027] The intermediate was obtained according to Example 1.

[0028] Take 15g of the above-mentioned intermediate and dissolve it in 15mL of chloroform, add 5.2g of ethanolamine at room temperature, stir and raise the temperature to 35°C for 4h. The solvent was distilled off under reduced pressure to obtain 20 g of light yellow viscous liquid, designated as J-02.

[0029] Product Characterization IR (cm-1): 3367, 2935, 2879, 1727, 1694, 1656, 1548, 1462, 1119, 1058

Embodiment 3

[0031] The intermediate was obtained according to Example 1. The preparation of methyl aziridine is obtained by sulfuric acid method with isopropanolamine as raw material.

[0032] Take 15 g of the above intermediate, dissolve it in 15 mL of dichloroethane, add 4.8 g of methyl aziridine dropwise at 5 °C, stir and raise the temperature to 10 °C for 12 h. The solvent was distilled off under reduced pressure to obtain 18.1 g of light yellow viscous liquid, designated as J-03.

[0033] Product Characterization IR (cm-1): 3423, 2966, 2930, 2879, 1731, 1692, 1459, 1171

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com