Pressure sensitive adhesive composition and product thereof

A composition and pressure-sensitive adhesive technology, applied in the direction of pressure-sensitive films/sheets, non-polymer organic compound adhesives, adhesives, etc., can solve problems such as deterioration of adhesion and unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Preparation of pressure sensitive adhesive composition

[0040] There is no particular limitation on the preparation method of the pressure-sensitive adhesive composition, for example, solution polymerization, suspension polymerization, emulsion polymerization, UV light or electron beam printing and distribution polymerization can be used.

[0041] The pressure-sensitive adhesive composition of the present invention is prepared by methods or steps known in the industry, such as the method mentioned in patent WO200494549A1: (1) preparing acrylate copolymer; (2) preparing acrylate oligomer; (3) preparing The prepared acrylate copolymer and acrylate oligomer are mixed and a certain amount of crosslinking agent is added to finally obtain the desired pressure-sensitive adhesive solution.

[0042] Preparation of pressure sensitive tape

[0043] The pressure-sensitive adhesive composition involved in the present invention can be coated with a high molecular weight, low gl...

specific Embodiment approach

[0049] Item 1 is a pressure-sensitive adhesive composition comprising the reaction product of the following reaction components: an acrylate copolymer having pendant carboxyl groups formed from a first monomer mixture containing a carboxyl-containing monomer, wherein the carboxyl-containing monomer The content is 0.1-10wt.%, with the total weight of the first monomer mixture used to form the acrylate copolymer with side carboxyl group as 100wt.%, the glass transition of the acrylate copolymer with side carboxyl group The temperature Tg is greater than or equal to -55°C, and less than or equal to -30°C; 1-25wt.% of acrylate oligomers, based on the total weight of acrylate copolymers and acrylate oligomers with side carboxyl groups as 100wt. %, the weight-average molecular weight of the acrylate oligomer is greater than or equal to 20,000 Da, and its glass transition temperature Tg is greater than or equal to 25 ° C; The total weight of the carboxyl acrylate copolymer and acryla...

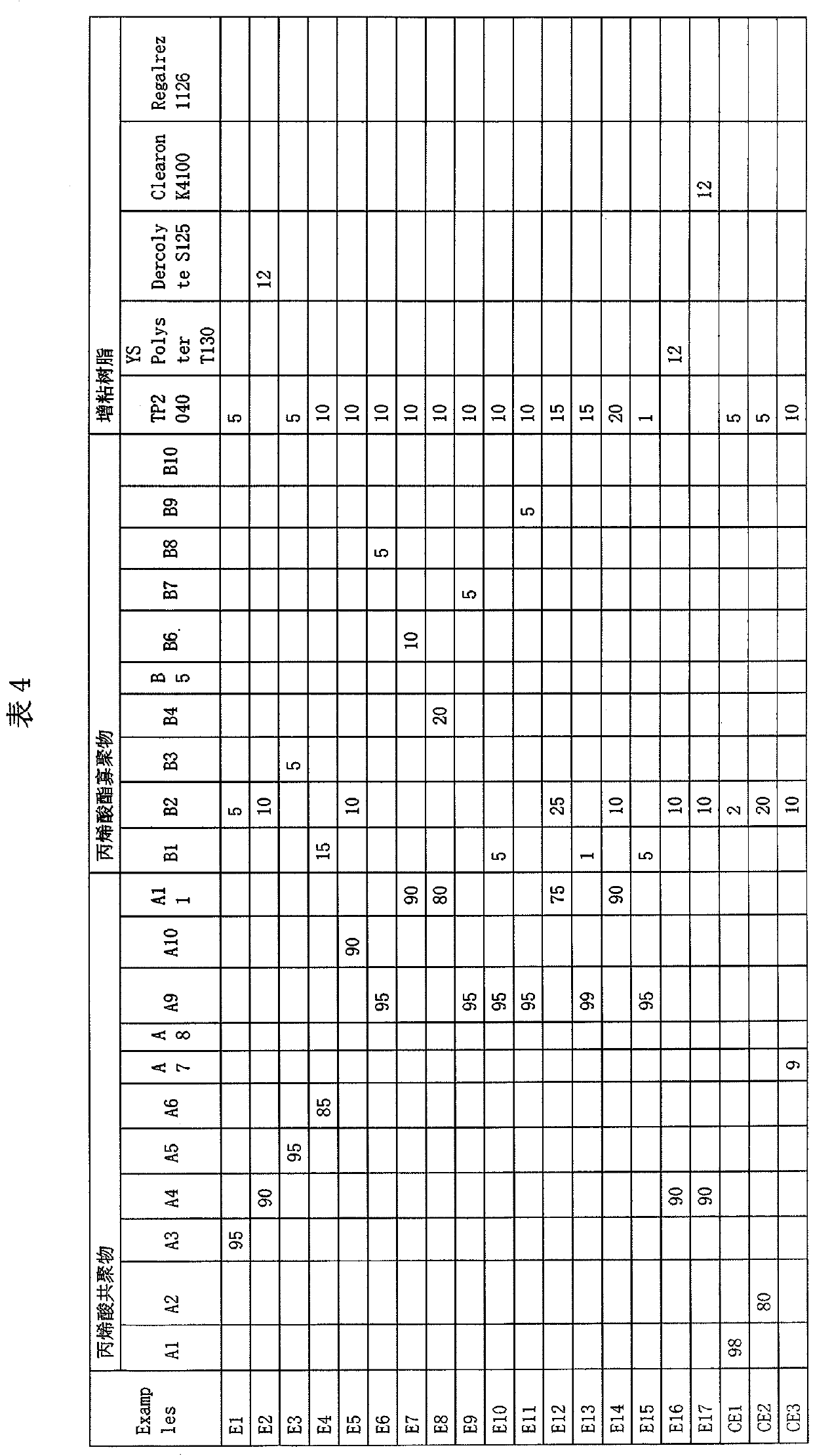

Embodiment

[0062] The present invention will be described more specifically below in conjunction with examples, but the present invention is not limited to these examples.

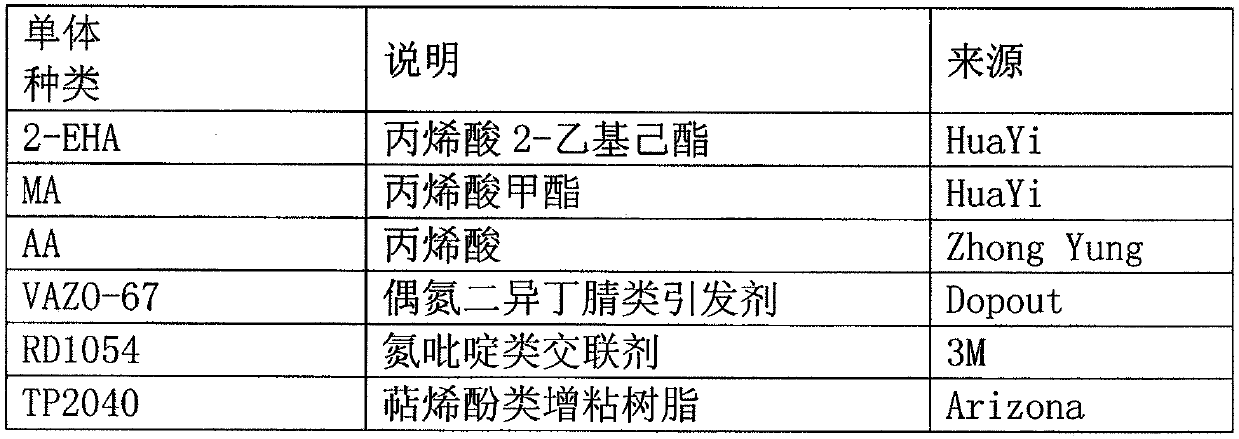

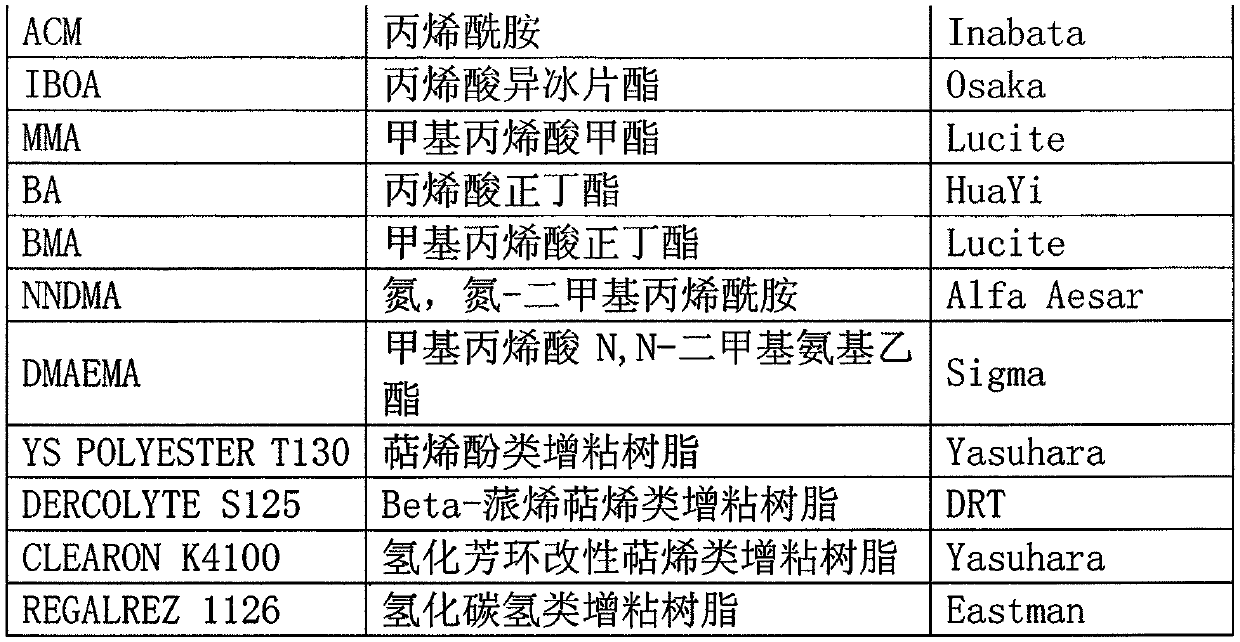

[0063] raw material

[0064] The raw material that the embodiment of the present invention adopts is listed as table 1:

[0065] Table 1

[0066]

[0067]

[0068] testing method

[0069] Peel force test at room temperature at 180°C

[0070] The test procedure for peel force at room temperature at 180°C is as described in ASTM International Standard D3330. The test was completed on an Instron tensile tester with a peeling speed of 304.8 / min. The substrate to be adhered is polycarbonate PC board. The PC board is brand new, tear off the protective film on one side to expose a fresh surface as the surface to be glued. The sample preparation method is to roll a 25.4mm*200mm tape sample back and forth with a 1kg rubber roller once to adhere to the surface of the PC board, and place the sample to be tested ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com