Thermal insulation and noise reduction cylinder of compressor

A compressor and noise reduction technology, which is applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems affecting compressor performance, reducing compression ratio, and high thermal conductivity, so as to improve overall performance, increase refrigerant volume, and improve The effect of volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

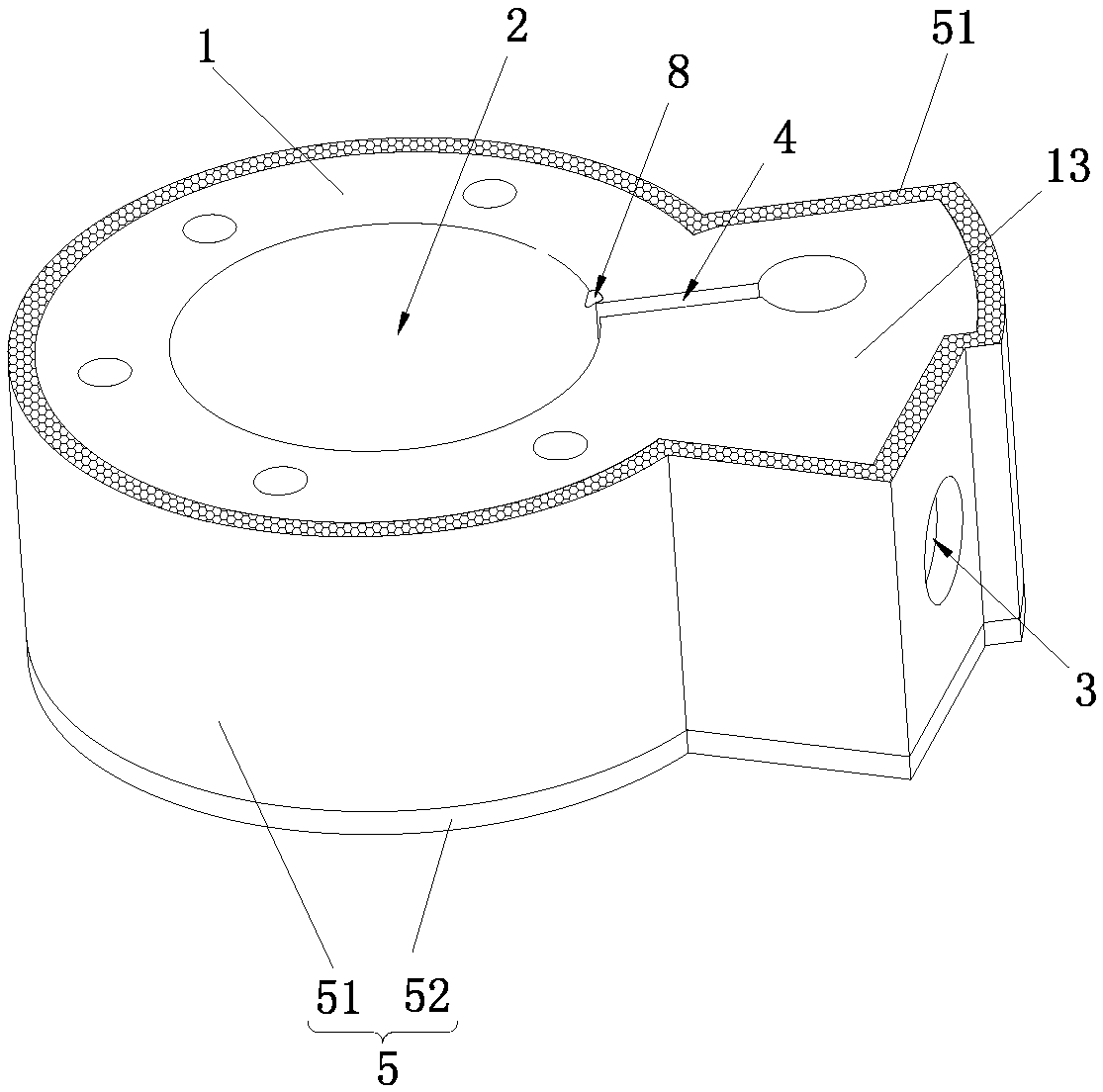

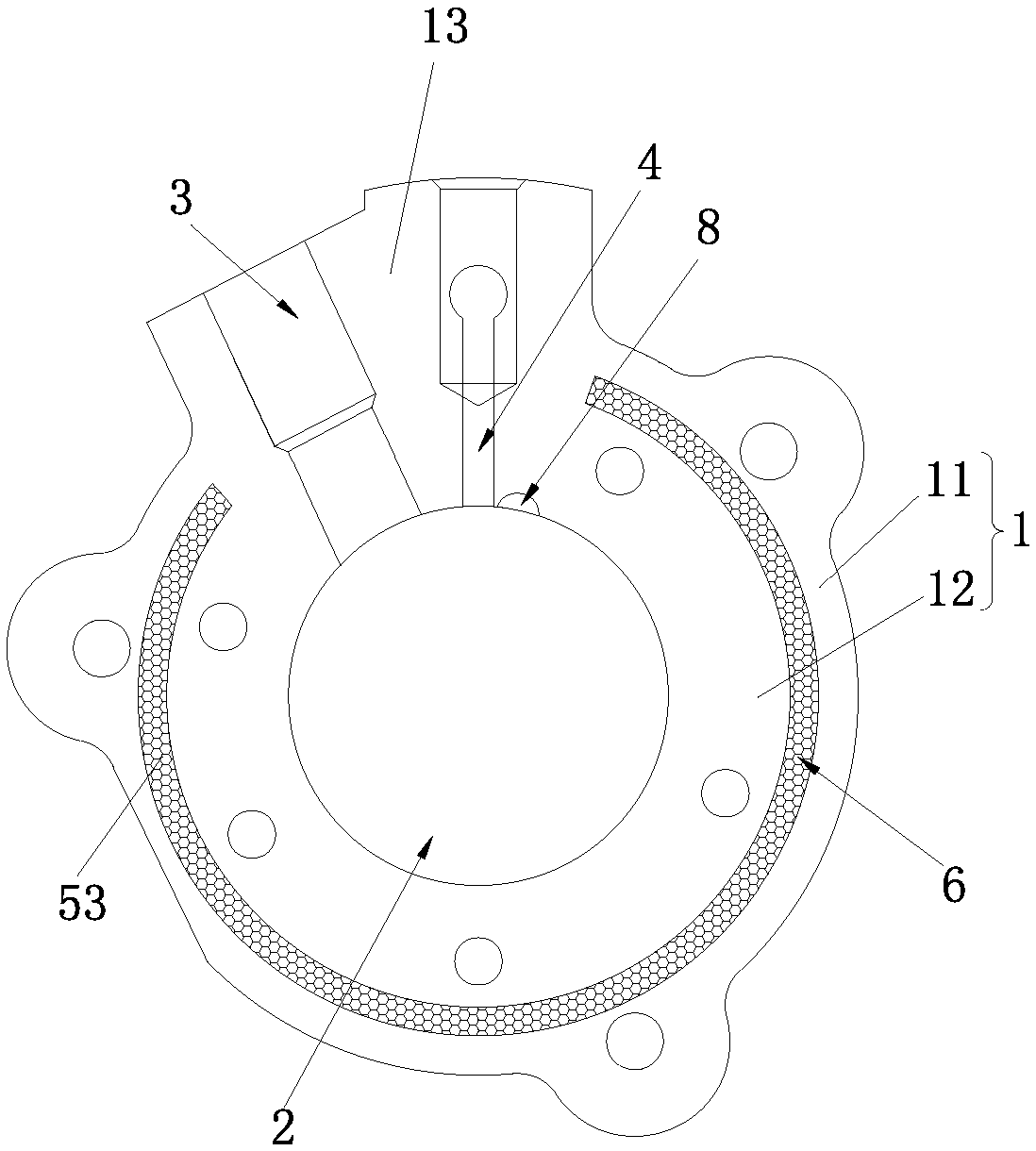

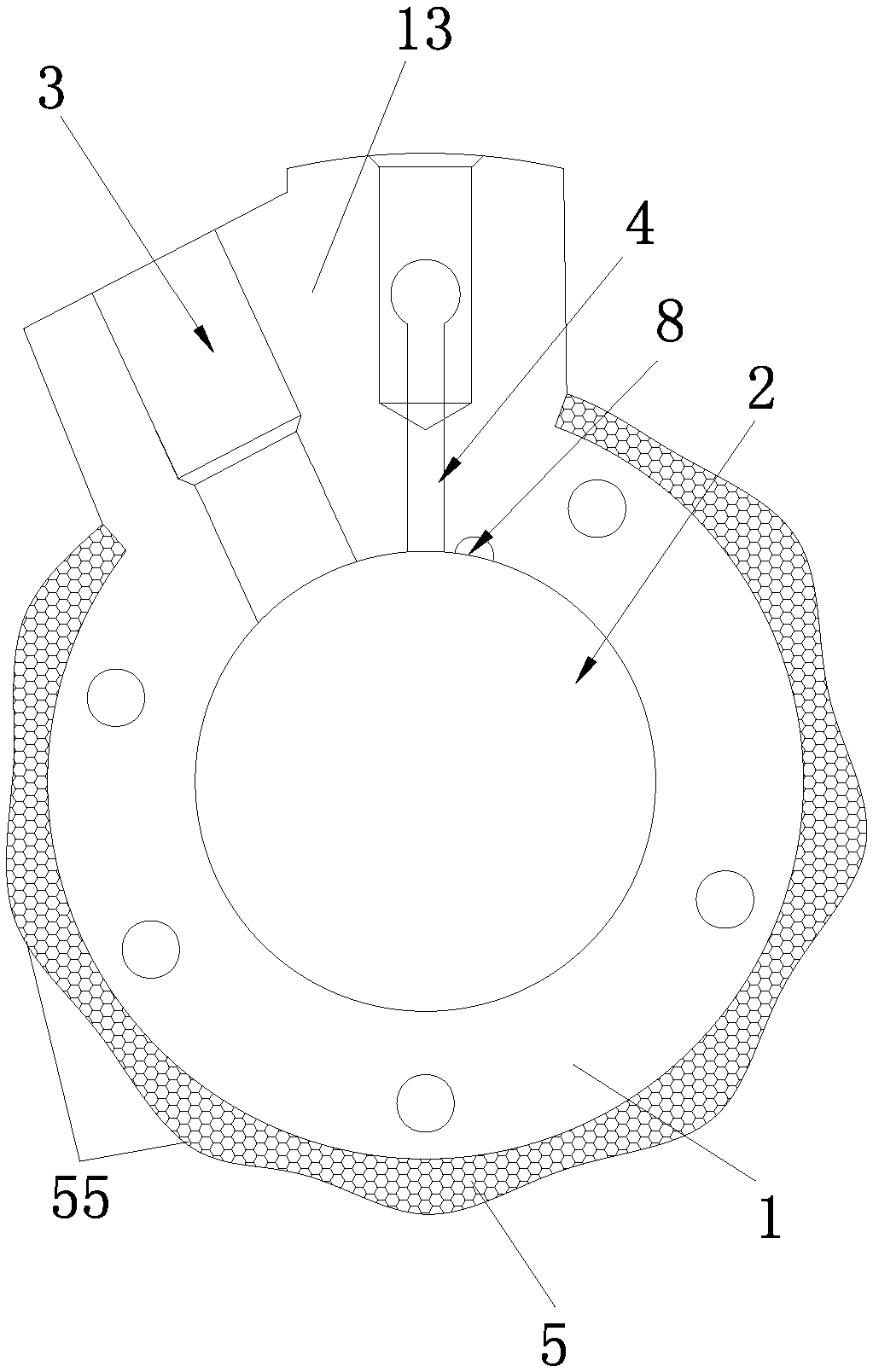

[0057] like figure 1 , 2 As shown, a compressor heat-insulating and sound-absorbing cylinder of the present invention includes at least two layers of materials with different thermal conductivity, and also includes: cylinder body: the cylinder body 1 is provided with a compression chamber 2 and an air inlet 3 communicating with the compression chamber 2 , the exhaust port 8 and the sliding vane groove 4 communicating with the compression chamber 2; the upper end surface and the lower end surface of the cylinder body 1 are provided with mounting holes 14; the heat-insulating and sound-absorbing parts 5, the heat-insulating and sound-absorbing parts 5 are materials with low thermal conductivity; Isolate the heat exchange between the compression chamber 2 and the outside world. The heat insulation and noise reduction part 5 is a material with low thermal conductivity and is installed on the surface of the cylinder body 1 or inside the cylinder body 1 to isolate the heat exchange ...

Embodiment 2

[0066] like figure 1 , 2 As shown, a compressor heat-insulating and sound-absorbing cylinder of the present invention includes a cylinder body 1, and the cylinder body 1 is provided with a compression chamber 2, an air intake hole 3 communicating with the compression chamber 2, and a sliding vane groove 4 communicating with the compression chamber 2 , and also includes a heat insulating and sound-absorbing member 5 for slowing down the heat exchange between the compression chamber 2 and the outside, and the heat-insulating and sound-absorbing member 5 is arranged on the cylinder body 1 . A compressor generally includes a crankshaft, a piston, a cylinder, an upper bearing and a lower bearing, the cylinder is arranged between the upper bearing and the lower bearing, the piston is arranged in the compression chamber 2 of the cylinder, and the crankshaft is passed through the upper bearing and the lower bearing to drive the piston to rotate , the motor drives the crankshaft to ro...

Embodiment 3

[0076] like Figure 10 As shown, the difference between the present embodiment and the second embodiment is that the heat insulation cavity 6 is a closed heat insulation cavity. Specifically, a semi-circular cavity with one end open and the other end closed can be milled on the cylinder body 1 first. Close the hollow body.

[0077] The rest of this embodiment is the same as that of Embodiment 2, and the features not explained in this embodiment are all explained in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com