A microwave low-temperature smelting device for laterite nickel ore

A smelting device and a technology for laterite nickel ore, which is applied in the field of laterite nickel ore smelting and application devices, can solve problems such as unusability, damage, and unfavorable normal work, and achieve the effects of protecting the use temperature, preventing the change of properties, and enhancing the absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

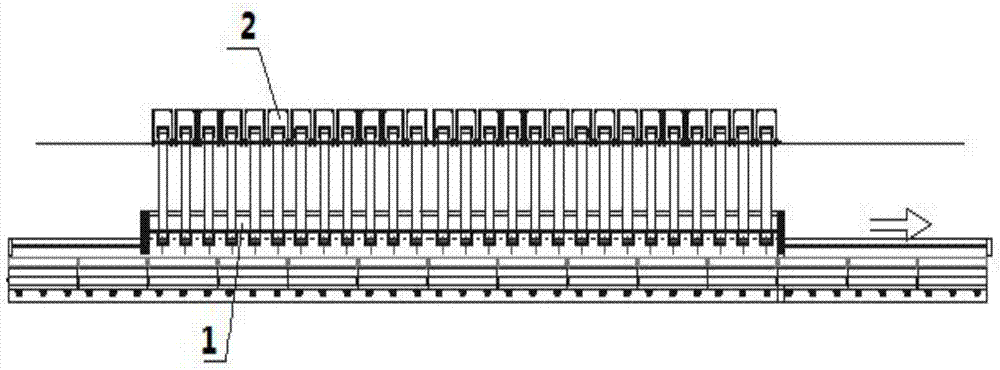

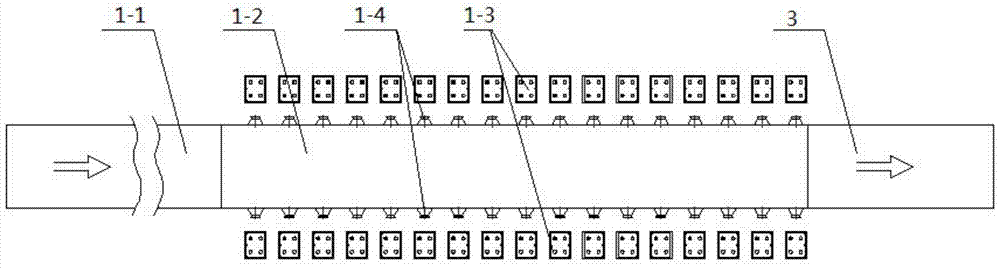

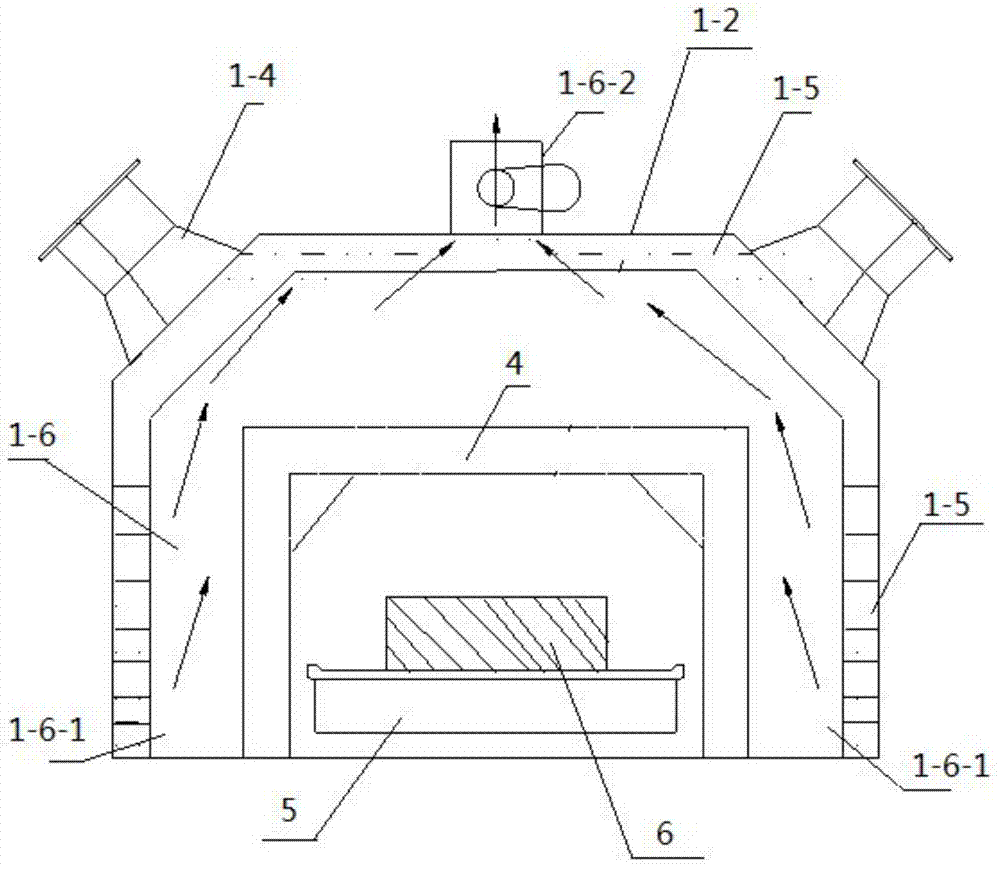

[0040] like Figure 1 to Figure 4 As shown, a microwave low-temperature smelting device for laterite nickel ore, which includes a continuous high-temperature tunnel kiln body (1), microwave sources and control parts (2) erected on both sides of the continuous high-temperature tunnel kiln body (1); The continuous high-temperature tunnel kiln body (1) includes a preheating section (1-1), a microwave heating cavity (1-2), an energy-feeding waveguide group (1-3) connected to the microwave heating cavity (1-2) and Microwave energy feed port (1-4), and a microwave leakage suppression device (3) installed at the end of the microwave heating cavity (1-2); the microwave source and control part (2) includes a microwave output cabinet and a power control cabinet ;

[0041] The microwave energy of the microwave output cabinet is multiplexed into the microwave heating cavity (1-2) from the side of the microwave heating cavity (1-2) through the microwave energy feed port (1-4);

[0042] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com