Method for detecting defects of metal bellows based on laser vibration

A technology for metal bellows and vibration detection, which is applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. It can solve problems such as increasing the difficulty of laser vibration data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

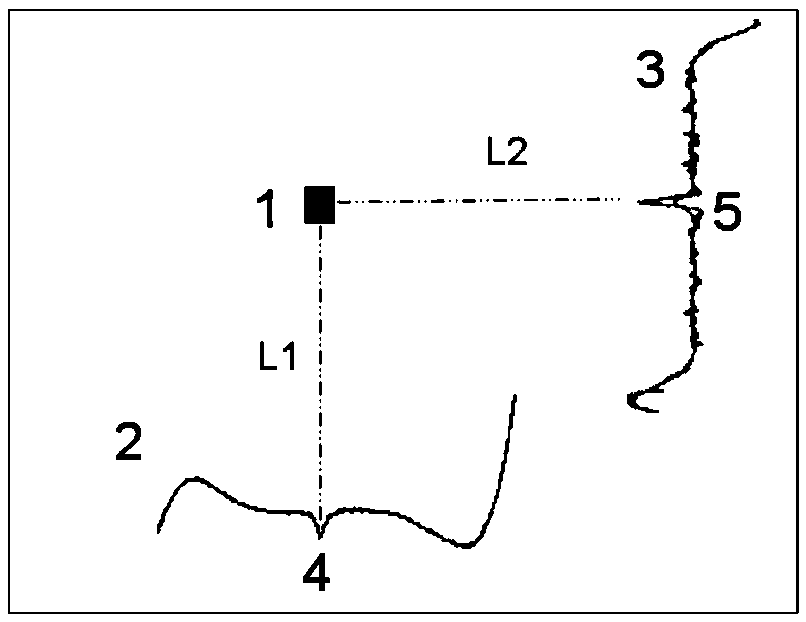

[0088] In the method for detecting metal bellows defects based on laser vibration in this embodiment, the metal bellows to be tested has a typical structure, such as figure 1 As shown, the outer diameter of the straight section of the bellows D o =278mm, average diameter D m =315.86mm, thickness h=1.44mm, number of layers n=1, wave number β=8, wave height h=39.3mm, wave pitch q=33mm, free length at both ends L=296mm, bellows are made of 304 stainless steel. The bellows has an artificial external defect in the middle of the 4th wave.

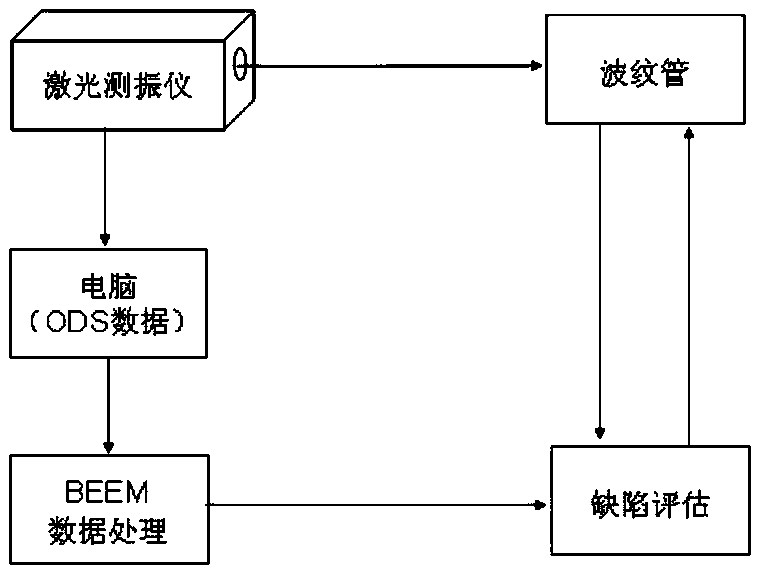

[0089] The main process of actual detection in this embodiment can be found in figure 2 ,Specific steps are as follows:

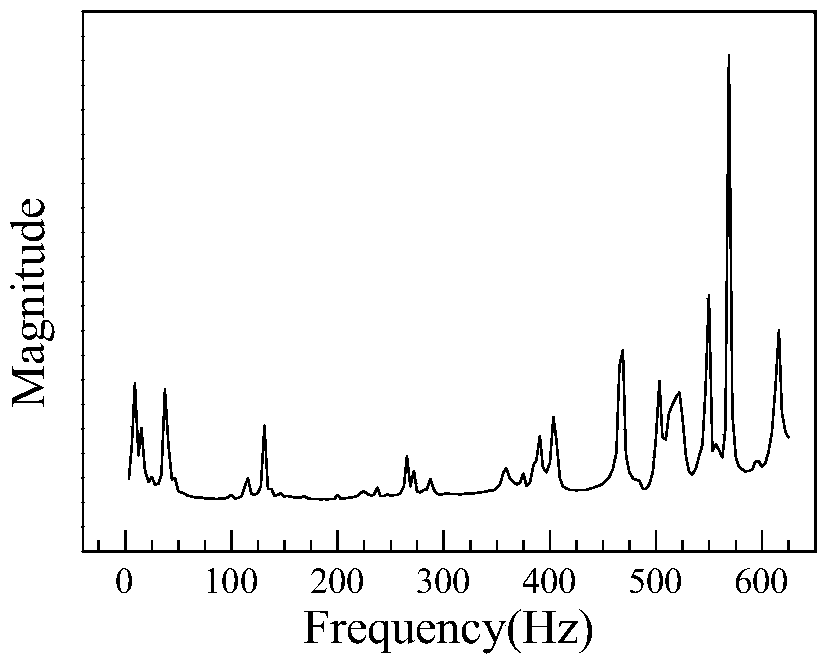

[0090] Step 1: Vibration excitation—use the PZT piezoelectric ceramic sensor to excite the detected metal bellows, fix the bottom of the metal bellows, attach the PZT piezoelectric ceramic sensor to the first wave position of the bellows, and use the piezoelectric power amplifier ( PiezoPowerAmplifier) amplifies the inp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com