Bisoprolol-containing adhesive patch and packaging body therefor

A bisoprolol and patch technology, which is applied in the field of patches containing bisoprolol, can solve the problems of difficulty in taking out the patch, reduced release liner peelability, etc., and achieves easy removal, reduced contact area, and reduced adhesion area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1

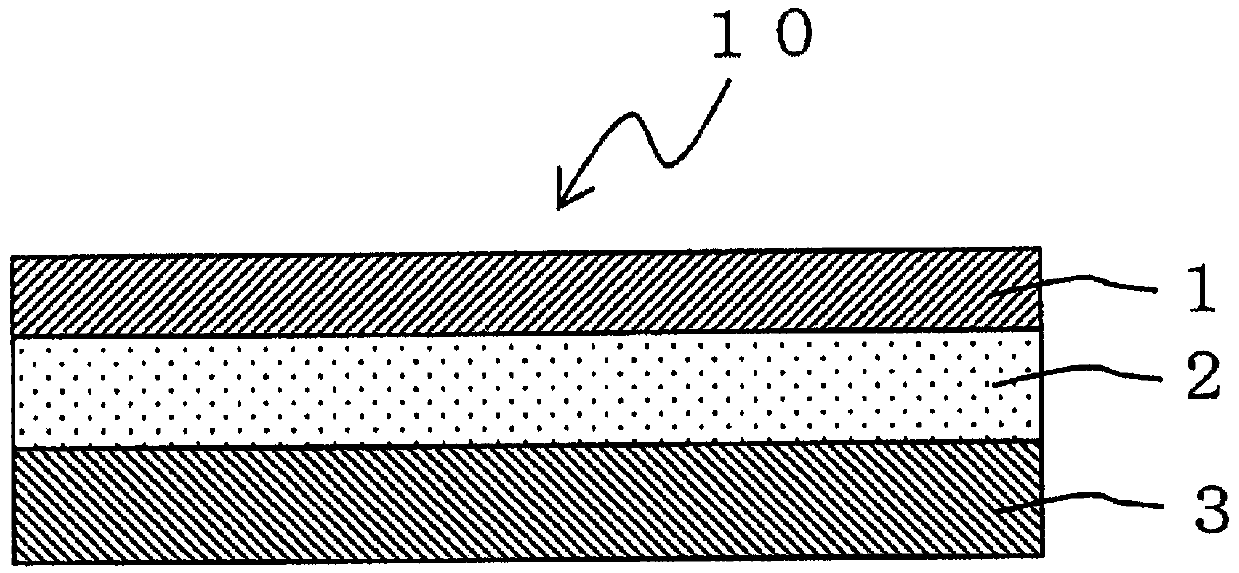

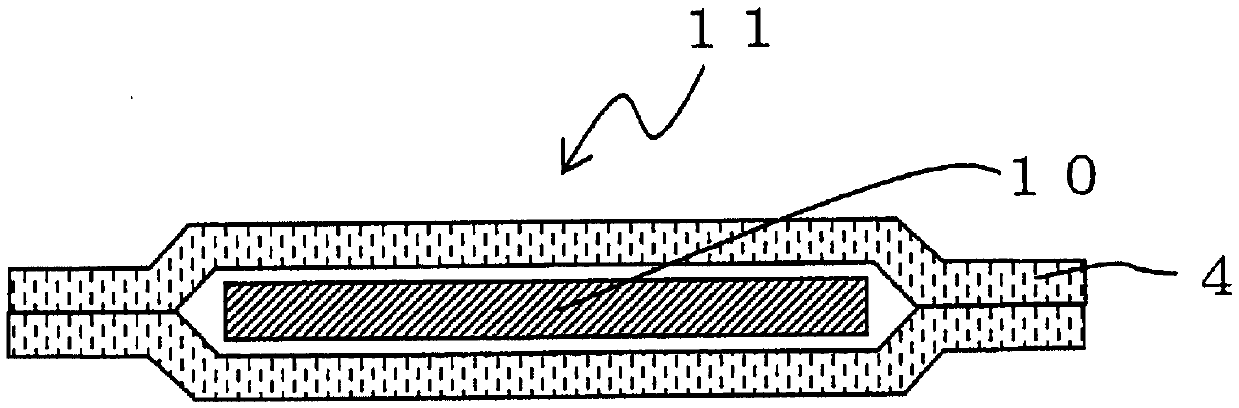

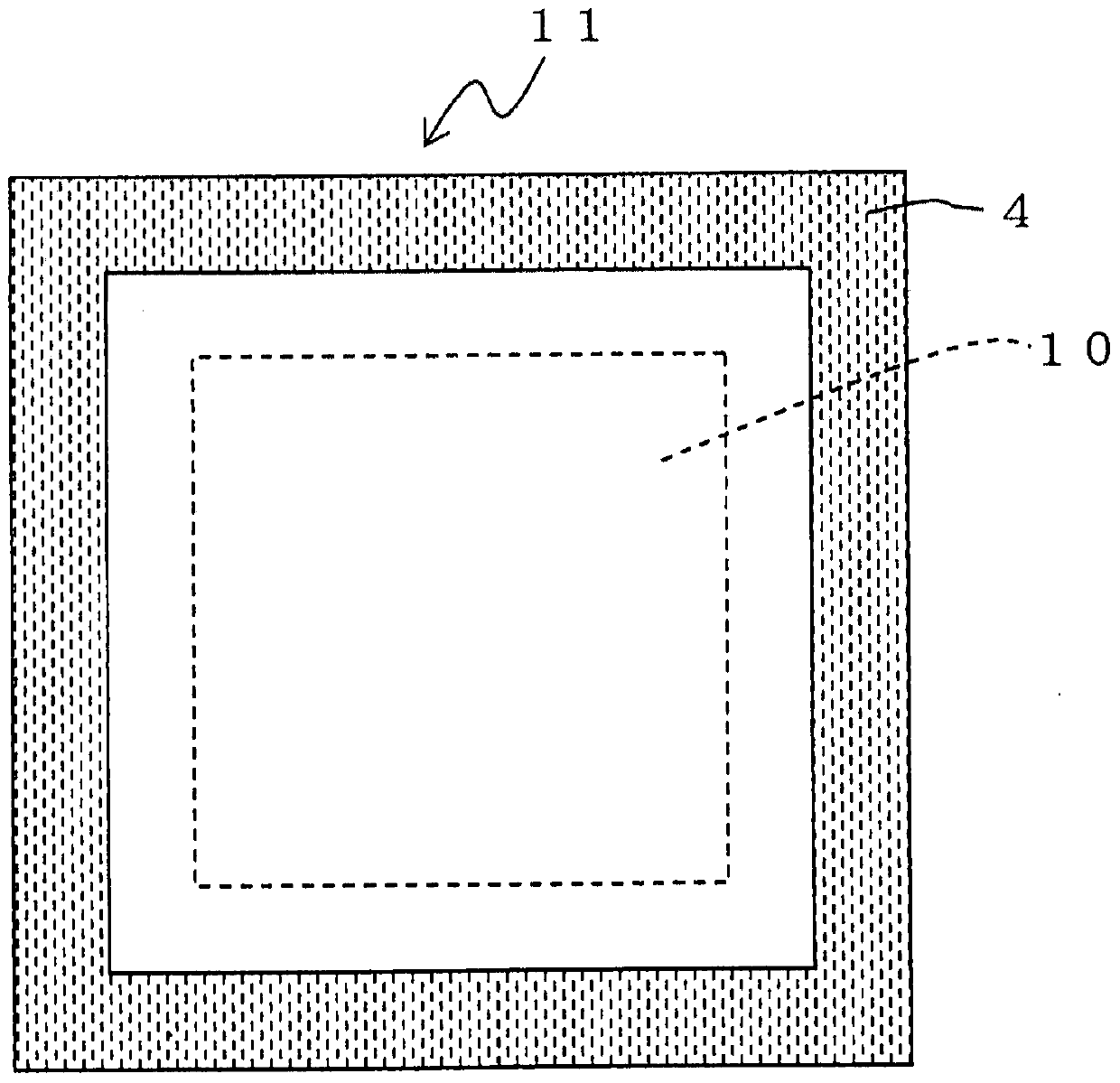

[0104] 13.72 parts of high molecular weight polyisobutylene (viscosity average molecular weight = 4,000,000), 27.44 parts of medium molecular weight polyisobutylene (viscosity average molecular weight = 55,000), 27.44 parts of alicyclic saturated hydrocarbon resin (tackifier), isopropyl myristate ( 30.00 parts of organic liquid components) and 1.40 parts of bisoprolol (free body) were mixed in toluene to prepare a viscous toluene solution of the adhesive composition. The obtained solution was coated on various polyethylene terephthalate (PET) release liners (thickness: 75 μm) described in Table 1 so that the thickness after drying was 200 μm, and it was dried in hot air. Dry at 100° C. for 5 minutes in a circulating dryer to form an adhesive layer. The pressure-sensitive adhesive layer was bonded to a PET film (thickness 2 μm) and a PET nonwoven fabric (weight per unit area = 12 g / m 2 ) on the non-woven fabric side of the support of the laminated film, pressurize the peripher...

experiment example

[0107] (1) Peeling force

[0108] Each of the bisoprolol-containing patches of Examples 1 to 3 and Comparative Example 1 was cut into strips with a width of 24 mm, and each was used as a sample. One end of each sample was peeled off, and a release liner and an adhesive sheet were fixed on one chuck of a tensile testing machine (small benchtop testing machine EZTestEZ-S, manufactured by Shimadzu Corporation), and the Under the conditions of 23±2°C and 50±10% R.H., peel and measure along the direction of 180 degrees at a speed of 300mm / min. The measurement results are shown in Table 1 together.

[0109] (2) Removal

[0110] The packs of the bisoprolol-containing patches of Examples 1 to 3 and Comparative Example 1 were opened by expert panelists, and the ease of taking out the patches from the packages was evaluated. The above evaluation was carried out 5 times, and the cases where all were evaluated as easy to take out were set as "○", the cases where not all but several tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com