Evaluation equipment for oxide semiconductor thin films

An oxide semiconductor and evaluation device technology, applied in measurement devices, semiconductor/solid-state device testing/measurement, material analysis using microwave means, etc. The effect of reducing setup space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

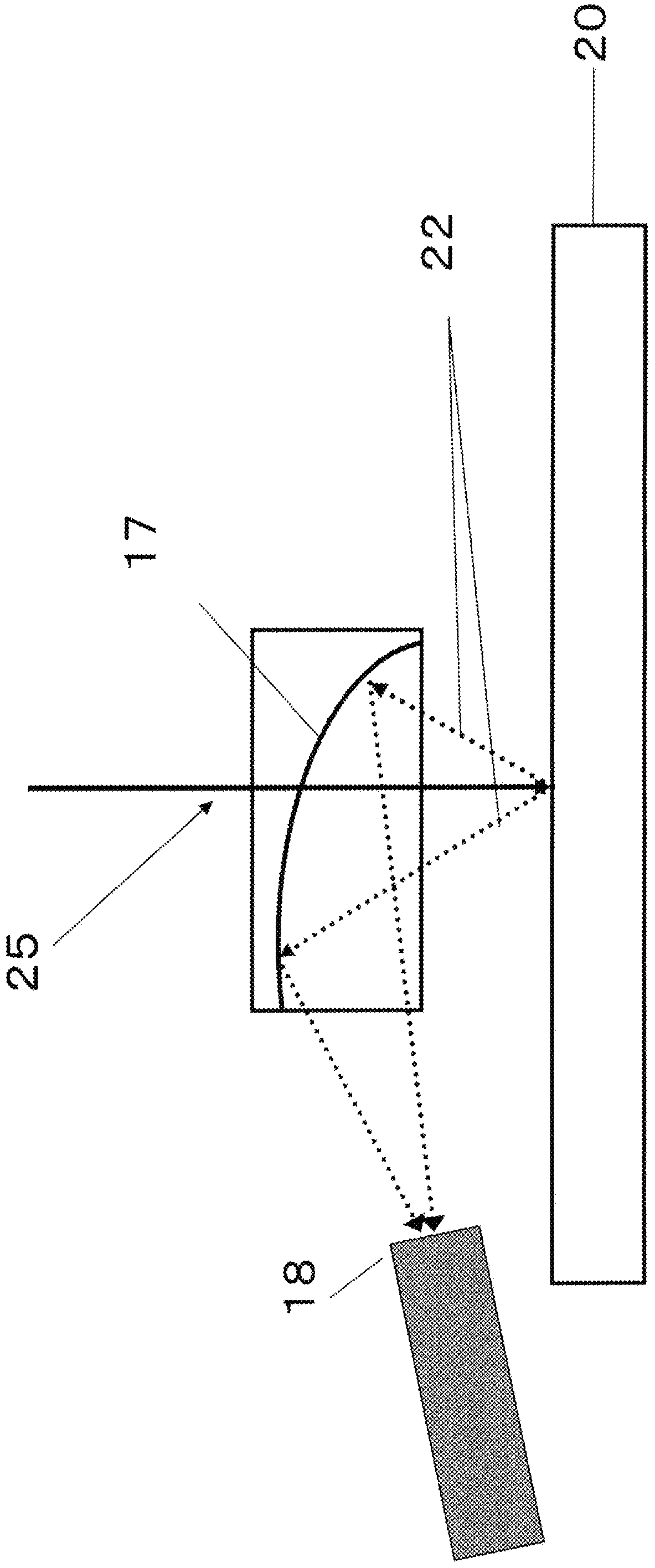

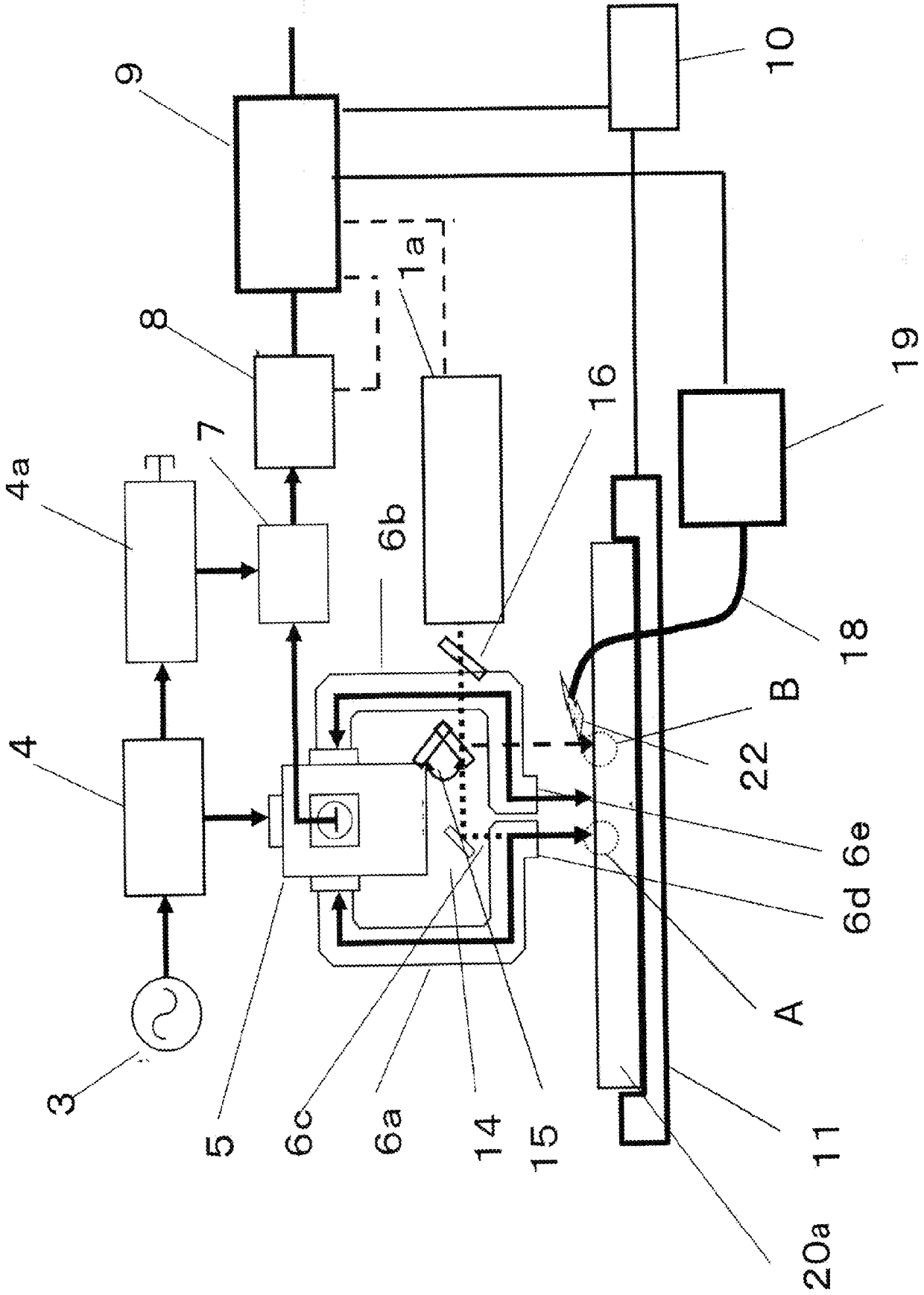

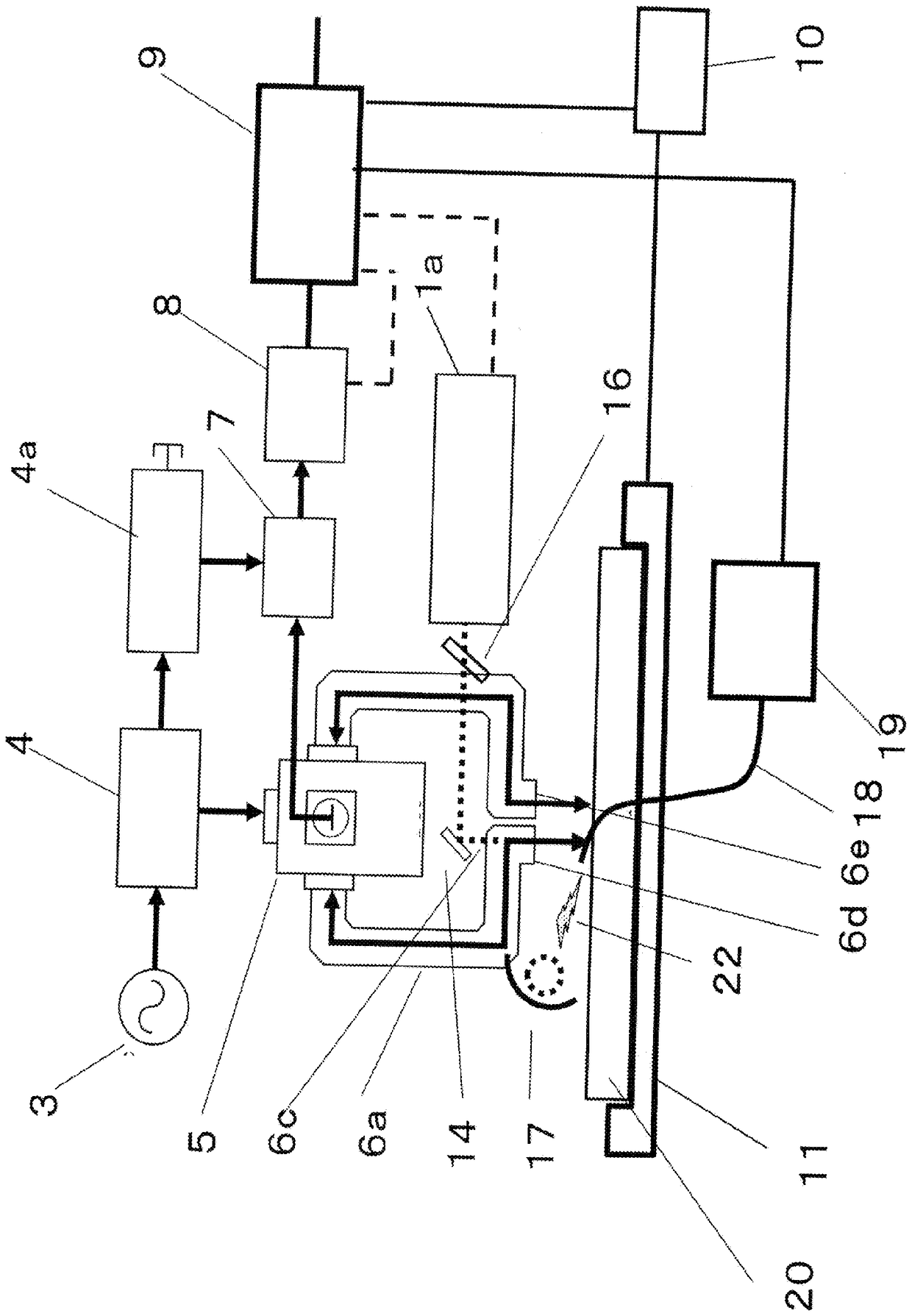

[0031] As already described, the present applicant proposed an evaluation method using a microwave photoconductivity decay method as a technique for evaluating the mobility of an oxide semiconductor thin film. The evaluation method by the microwave photoconductivity attenuation method is a non-contact measurement that does not require electrode addition and can be measured in a short time. Therefore, in the present invention, the known microwave photoconductivity attenuation method is also used. to evaluate.

[0032] On the other hand, since the stress tolerance cannot be evaluated by the previously proposed technique, the inventors of the present invention have intensively discussed the evaluation method of the stress tolerance repeatedly. As a result, it was found that, as an index for easily evaluating (predicting and estimating) the stress resistance of an oxide semiconductor thin film in a non-contact manner, measurement of photoluminescence light excited by irradiating a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com