Method for wet modification of emulsified asphalt with nano-clay/styrene butadiene rubber

A technology for emulsified asphalt and nanoclay, applied in building components, building insulation materials, construction and other directions, can solve the problems of poor storage stability, difficult to mix evenly, etc., and achieve the effects of stable performance, improved storage stability, and easy operation of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

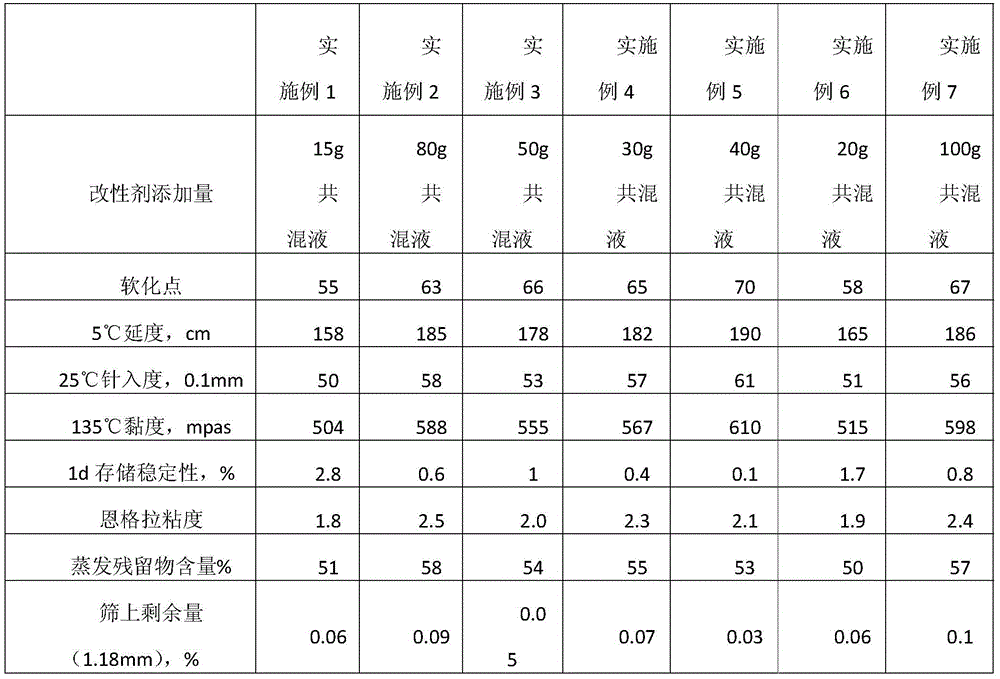

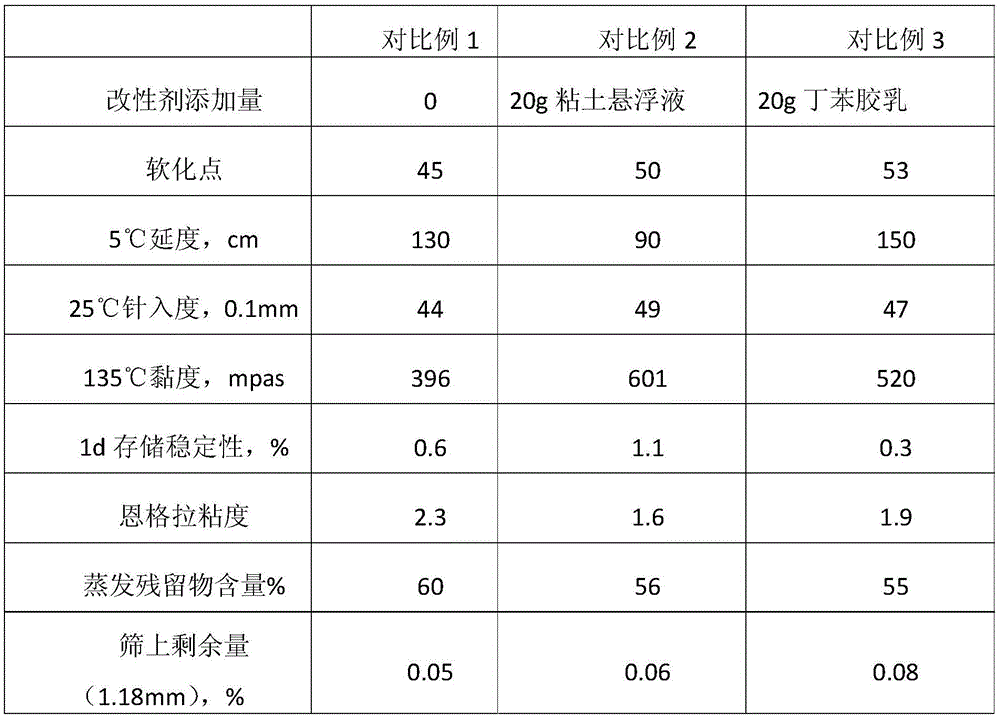

Examples

Embodiment 1

[0023] Take 0.5g of emulsifier, add 99.5g of water, and dissolve it completely in a water bath at 60°C to obtain an emulsified soap with a solid content of 0.5%, wherein the compound mass ratio of sodium dodecylbenzenesulfonate and alkylphenol polyoxyethylene ether It is 1:0.5. Take 100g of emulsified soap with a solid content of 0.5% and add it to 200g of No. 70 base asphalt at a temperature of 120°C, and emulsify in an emulsifier at 200r / min for 1min to obtain emulsified asphalt. Get 5g montmorillonite, add 95g water, obtain the clay suspension that solid content is 5% after stirring and mixing, get 100g solid content and be that 5% clay suspension is added to 100g mass fraction and be that the styrene-butadiene latex of 20% mixes evenly to obtain Nano clay / styrene butadiene rubber blend. Take 15g of nanoclay / styrene-butadiene rubber blend and mix with 300g of emulsified asphalt, and shear it for 3min at a speed of 300r / min in a high-speed shearing machine to obtain nanocla...

Embodiment 2

[0025] Take 20g of emulsifier, add 180g of water, and dissolve it completely in a water bath at 80°C to obtain an emulsified soap with a solid content of 10%, in which the compound mass ratio of sodium lauryl sulfate and alkylphenol polyoxyethylene ether is 1:5 . Take 200g of emulsified soap with a solid content of 10% and add it to 200g of No. 90 base asphalt at a temperature of 150°C, and emulsify in a 700r / min emulsifier for 5min to obtain emulsified asphalt. Get 20g kaolin, add 80g water, obtain the clay suspension that solid content is 20% after stirring and mixing, get 100g solid content and be that 20% clay suspension joins in 125g mass fraction and be that the styrene-butadiene latex of 20% mixes homogeneously to obtain nanoclay / SBR blend. Take 80g of nanoclay / styrene-butadiene rubber blend and mix with 400g of emulsified asphalt, and shear it for 10min at a speed of 700r / min in a high-speed shearing machine to obtain nanoclay / styrene-butadiene rubber-modified emuls...

Embodiment 3

[0027] Take 3g of emulsifier, add 147g of water, and dissolve it completely in a water bath at 70°C to obtain an emulsified soap with a solid content of 2%, in which the compound mass ratio of sodium lauryl sulfate and alkylphenol polyoxyethylene ether is 1:2 . Take 150g of emulsified soap with a solid content of 2% and add it to 200g of No. 90 base asphalt at a temperature of 130°C, and emulsify in a 400r / min emulsifier for 3min to obtain emulsified asphalt. Get 15g silica, add 85g water, obtain the clay suspension that solid content is 15% after stirring and mixing, get 100g solid content and be that 15% clay suspension joins in 225g mass fraction and be that the styrene-butadiene latex of 20% mixes homogeneously to obtain nanoclay / SBR blend. Take 50g of nanoclay / styrene-butadiene rubber blend and mix with 350g of emulsified asphalt, and shear it for 6min at a speed of 400r / min in a high-speed shearing machine to obtain nanoclay / styrene-butadiene rubber modified emulsifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com