Three-dimensional circular light system

A light and ring technology, applied in the field of optical fiber systems, to achieve the effect of high electro-optical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

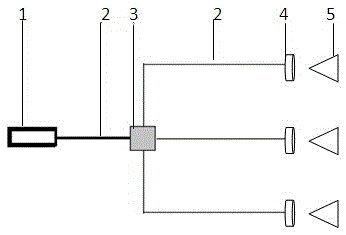

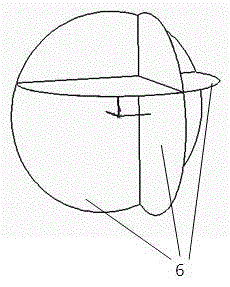

[0021] structure see figure 1 The light beam emitted by the laser point light source of the laser 1 is firstly coupled into the optical fiber 2 through a coupling mirror. After the three beams of laser light pass through the independent lens group 4 at the end, the divergence angle is compressed to a near-parallel light, and the light spot at this point is then passed through the reflective conical mirror 5 to obtain a 360° ring-shaped light. The ring-shaped light surface 6 is as figure 2 shown. The three laser beams are respectively arranged along the three-dimensional X, Y, and Z axis directions, so that the planes where the outgoing ring light rays are located are perpendicular to each other. In this embodiment, the laser is set as a semiconductor laser, and the optical fiber is set as a single-mode optical fiber.

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is that the laser in this embodiment is set as a solid-state laser, and the optical fiber is set as a multimode optical fiber.

Embodiment 3

[0025] The difference between this embodiment and Embodiment 1 is that the laser in this embodiment is set as a gas laser.

[0026] The wavelength of the laser used can be selected according to the needs of visible light or ultraviolet and infrared light for special purposes;

[0027] In the actual application of the three-dimensional light system of the present invention, more than one line may be required in a certain dimension, and ring light at a special angle may also be used, so the number of optical fiber beam splitting is not limited to three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com