Dynamic mine shoveling, transporting and dumping efficiency optimization system and method

A dynamic and mining technology, applied in the direction of instruments, data processing applications, forecasting, etc., can solve the problems of reducing production efficiency, inconvenience of production personnel, production confusion, etc., and achieve the effect of improving production efficiency, reducing loss, and strengthening practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

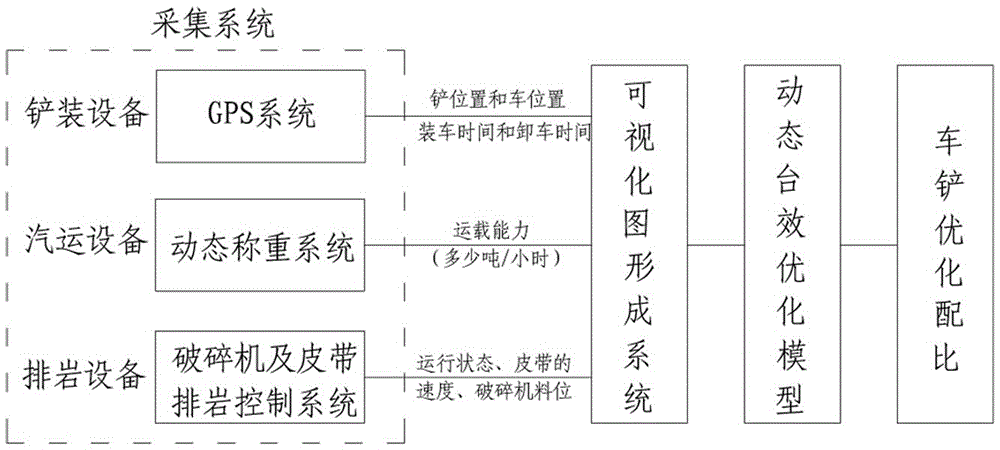

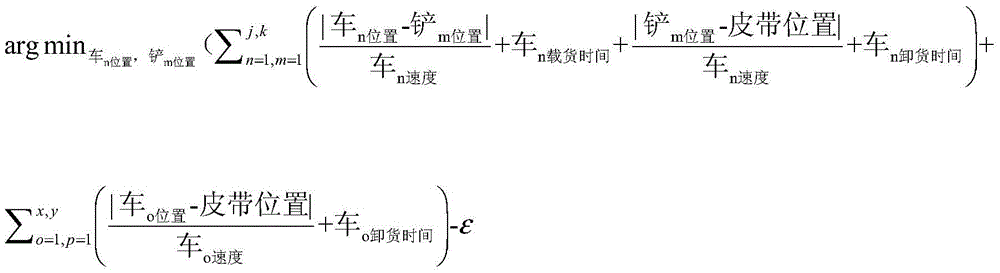

[0047] Such as figure 1 As shown, a mine shovel, transport and row dynamic efficiency optimization system and method is characterized in that it includes an acquisition system and a visual map forming system, and the output of the acquisition system includes the shovel position, vehicle position, loading time, unloading time, and carrying capacity. , how many tons per hour, operating status, belt speed and crusher material level are displayed in the visual map forming system, and a dynamic platform efficiency optimization model is established to calculate the ratio of trucks and shovels;

[0048] The collection system includes the GPS system of the shoveling equipment, the dynamic weighing system of the truck transport equipment, the crusher and the belt rock discharge control system of the rock discharge equipment.

[0049]The GP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com