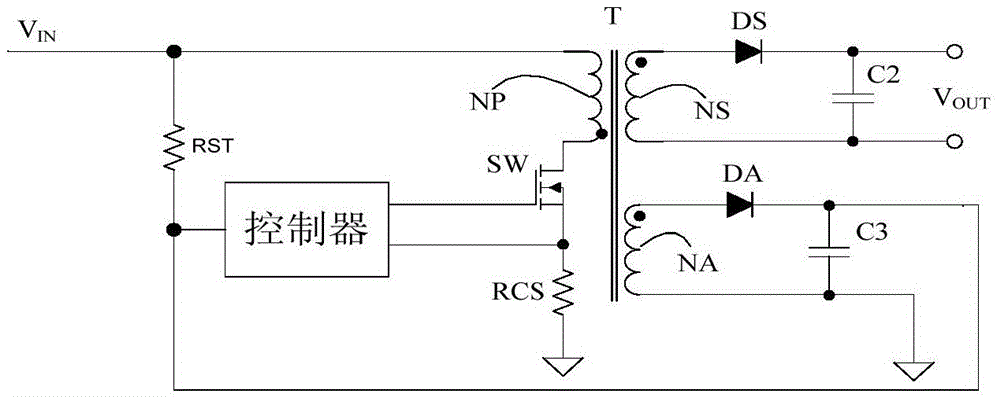

High-voltage start-up circuit

A high-voltage startup and startup capacitor technology, applied in emergency protection circuit devices, electrical components, output power conversion devices, etc., can solve problems such as heat accumulation, thermal damage to startup circuits, and virtual welding of startup capacitors, reducing short circuits. Power consumption, avoid overheating damage, avoid overvoltage damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

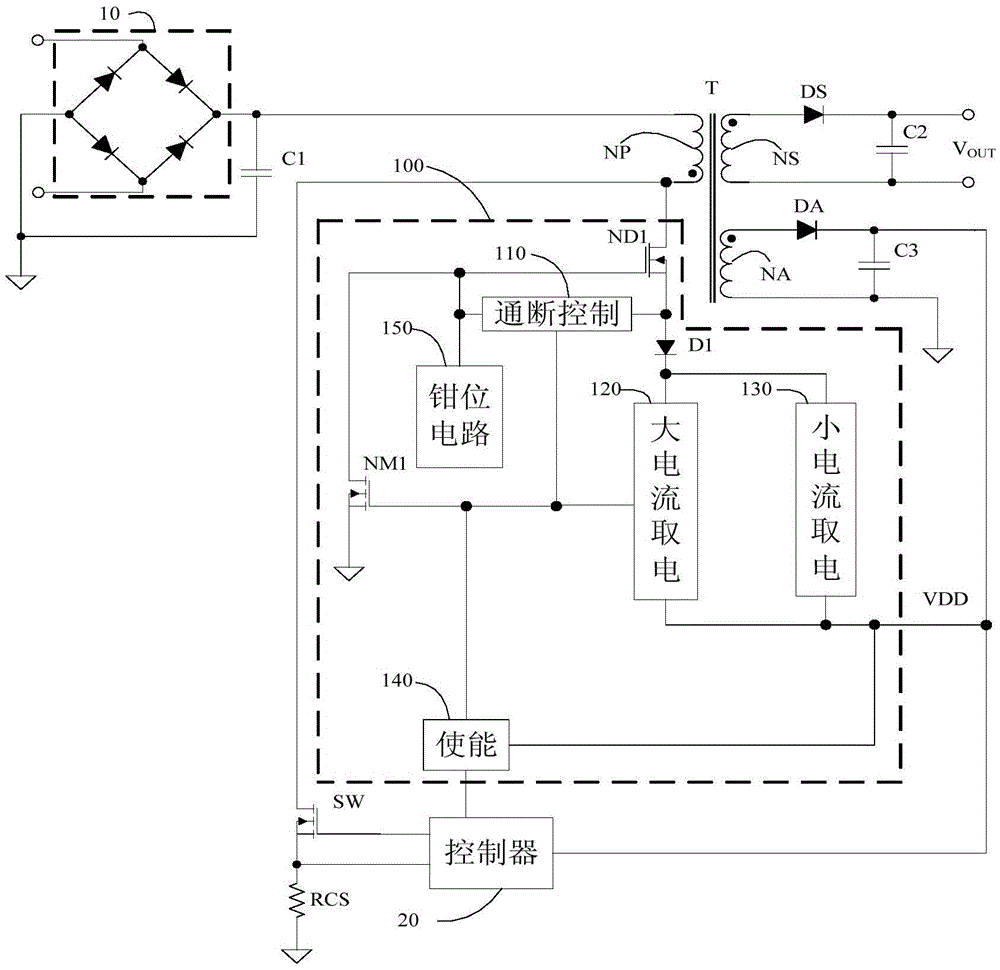

[0046] figure 2 Shown is the structural diagram of the high-voltage start-up circuit 100 of Embodiment 1 of the present invention, which is connected with the rectifier 10 and the transformer T to control the on-off and magnitude of the start-up current, which not only allows the controller 20 to start under normal conditions, but also Each circuit can be protected from being damaged under abnormal conditions. The high-voltage start-up circuit 100 includes a transistor ND1, an on-off control module 110, a diode D1, a large-current power-taking module 120, a small-current power-taking module 130, an enabling module 140, a clamping circuit 150, and an NMOS transistor NM1.

[0047] When the power supply is just powered on, the voltage of the power supply terminal VDD is 0V, and the enabling module 140 outputs a low-level signal, so that the NMOS transistor NM1 is turned off, the on-off control module 110 is turned on, and the transistor ND1 is turned on, so that the input power ...

Embodiment 2

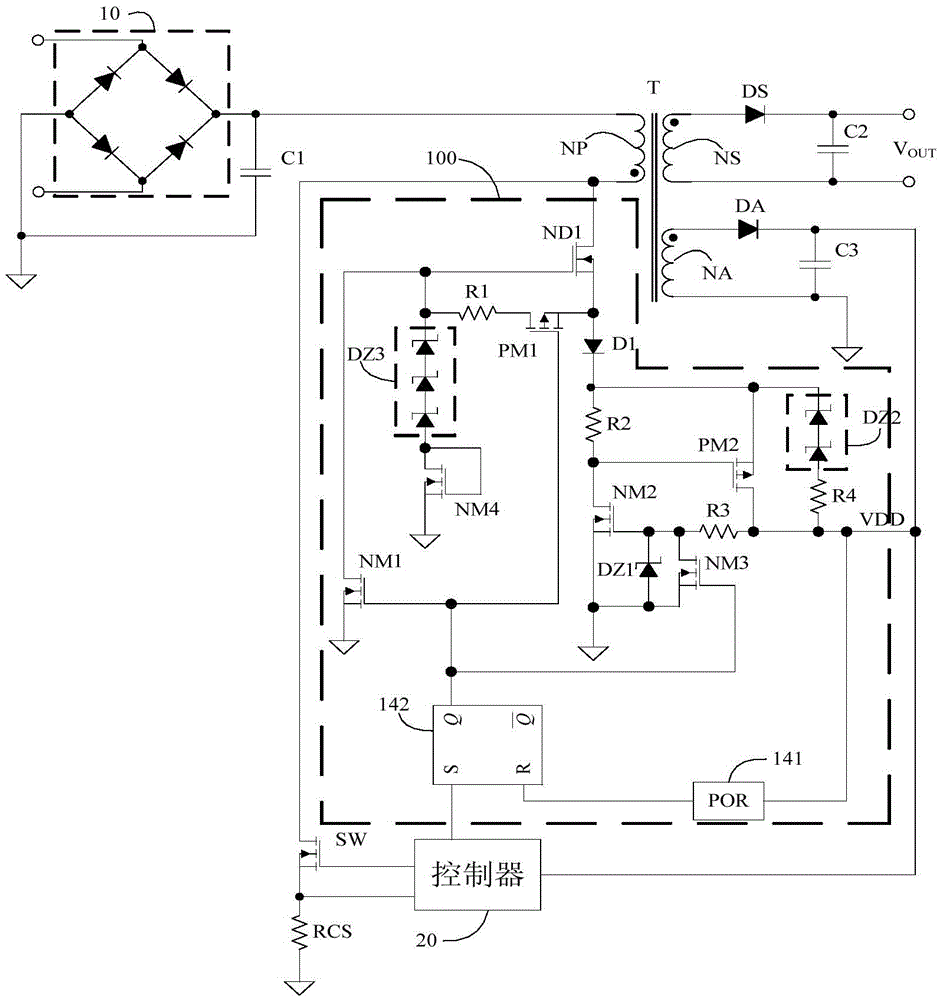

[0085] Figure 5 Shown is a detailed circuit schematic diagram of the high-voltage starting circuit of Embodiment 2 of the present invention. Such as Figure 5 As shown, different from Embodiment 1, in the process adopted in Embodiment 2, the threshold voltage of transistor ND1 is similar to the threshold voltage of PMOS transistor PM1, there is a risk that the on-off control module 210 cannot be turned on during the startup process, and then It affects the performance of the high-voltage starting circuit 200 , so in order to ensure the normal use of the high-voltage starting circuit 200 , in Embodiment 2, the on-off control module 210 includes a diode D2 and a resistor R1 , and the PMOS transistor PM1 is not used. One end of the resistor R1 is connected to the gate of the transistor ND1 , the other end of the resistor R1 is respectively connected to the source of the transistor ND1 and the cathode of the diode D2 , and the anode of the diode D2 is connected to the output of ...

Embodiment 3

[0089] Figure 6 Shown is a schematic structural diagram of a high voltage starting circuit 300 according to Embodiment 3 of the present invention. Such as Figure 6 As shown, the difference from Embodiment 1 is that the enabling module 340 of the high-voltage starting circuit 300 can control the high-voltage starting circuit 300 to cut off the charging current according to the received enabling signal from other circuits except the controller 20 . Other working processes and working principles of the high-voltage starting circuit 300 are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com