Evaporator for performing plant bionic remediation on contaminated soil

A plant bionic and polluted soil technology, applied in the field of soil remediation, to achieve the effect of improving remediation efficiency, speed and effect, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

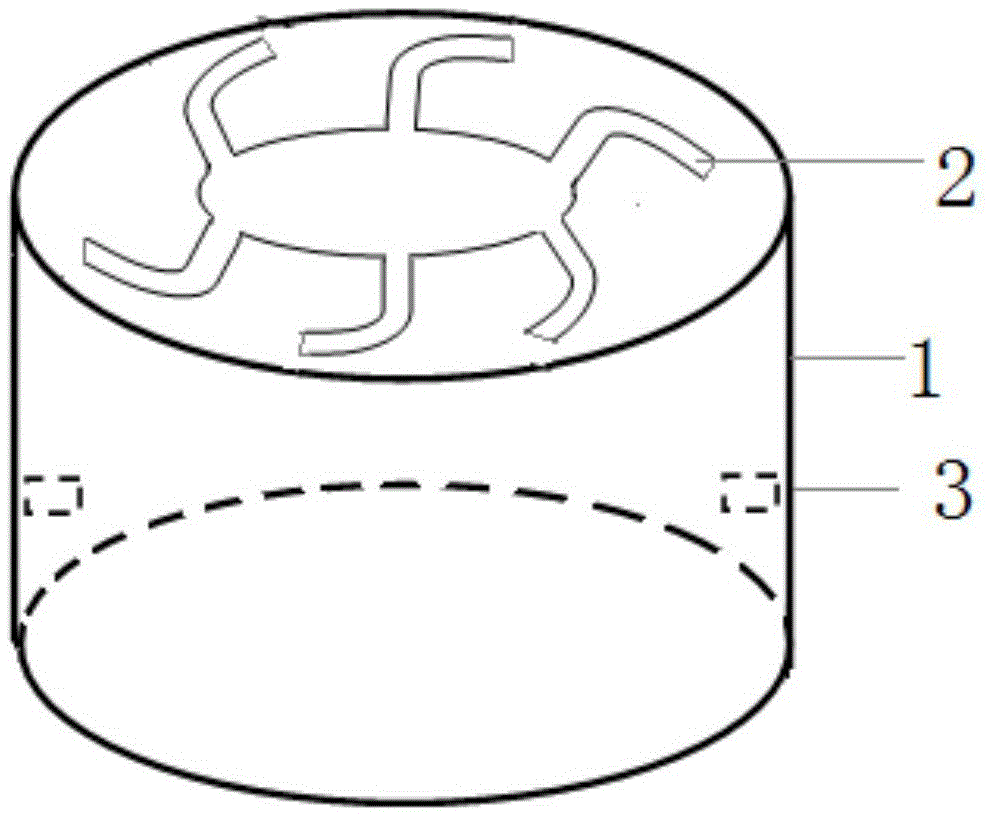

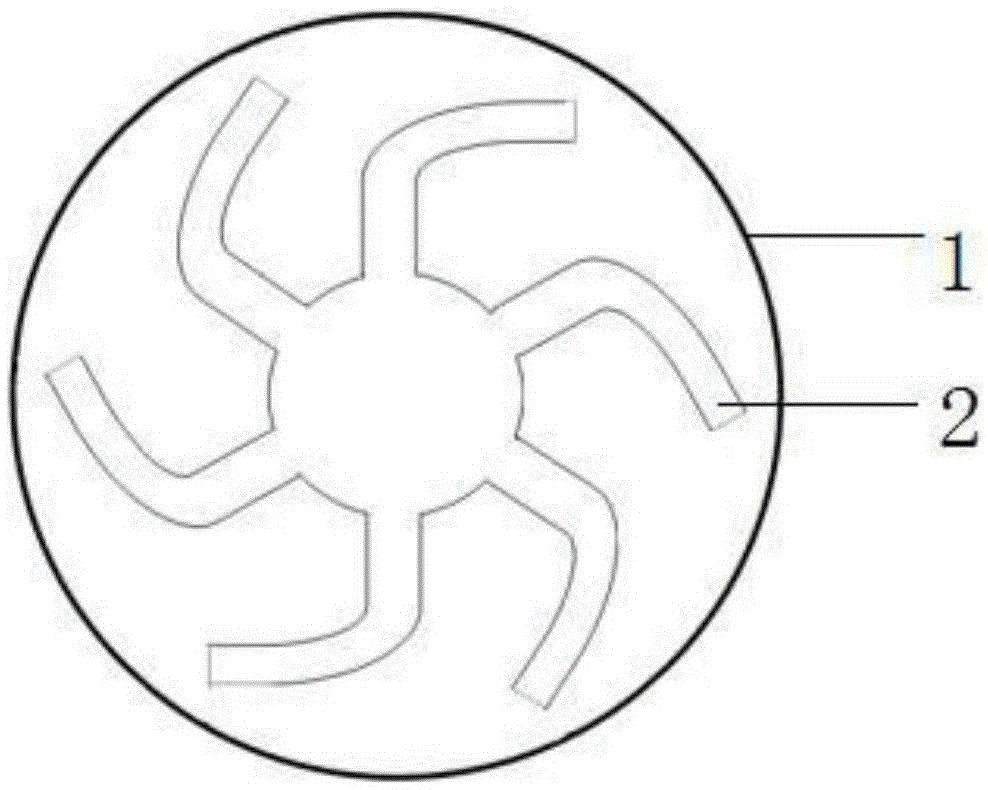

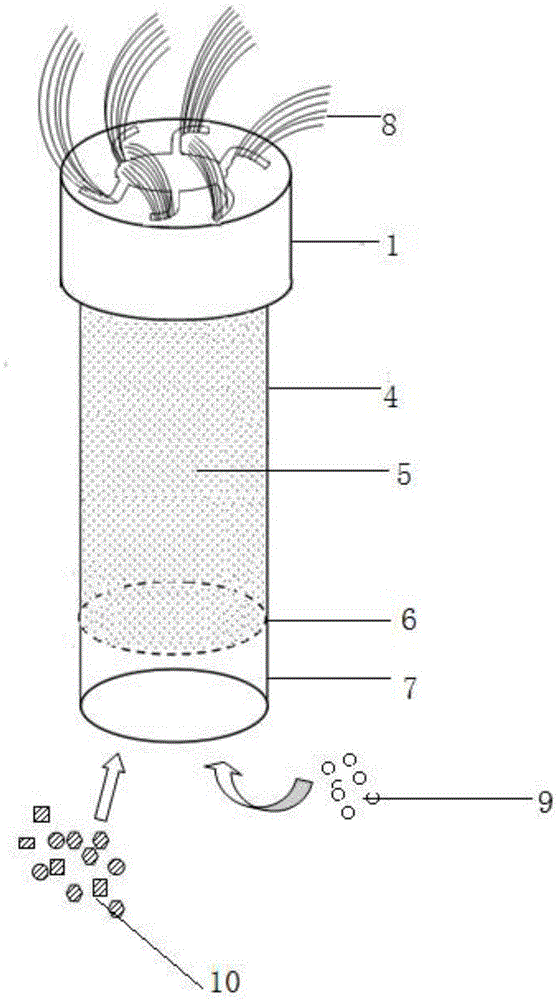

[0027] The structure of the in-situ self-sustaining repair device for contaminated soil based on plant bionics and the evaporator is as follows: image 3 Shown; The main part of the joint structure includes the repair device main body 4, filler repair agent 5, permeable membrane 6, accessories 7, evaporator main body 1 and evaporator fiber material 8. The main body of the repair device is a hollow pipe made of PVC material; the permeable membrane is attached to the bottom of the hollow pipe; the filler is tightly filled in the hollow pipe and compacted; the evaporator material is combined with the main body and fixed on the main pipe, and the evaporator fiber material penetrates Restorative filler.

[0028] Determination of transpiration rate of in-situ self-sustaining remediation device for contaminated soil based on plant bionics and comparison with plant transpiration rate. The transpiration rates of the glass fiber evaporator based on plant bionics of the present invention...

Embodiment 2

[0033] Remediation of industrially polluted soil by means of plant bionic remediation. The soil used in the test was taken from the polluted soil of an electroplating industrial park. According to the national soil environmental quality standard (GB15618-1995), the Cr and Ni in the polluted soil exceeded the natural background values by 28.4 times and 3.1 times respectively. Utilize the plant bionic restoration technology of the present invention's combined structure to carry out on-the-spot restoration of industrially polluted soil, the fiber material of the evaporator is glass fiber, as shown in Table 2: after 1 month, the Cr reduction rate in the soil is 27%, and the Ni reduction rate is 24%. %; After 2 months, the Cr reduction rate in the soil was 41%, and the Ni reduction rate was 37%.

[0034] Table 2 Biomimetic remediation effect of contaminated soil

[0035]

[0036] From the data in Table 2, it can be seen that the plant bionic remediation technology has a good ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com