Glass polishing brush and polishing method and polishing device

A polishing device and glass technology, which is applied to grinding drive devices, grinding/polishing equipment, brushes, etc., can solve the problems of uneven surface roughness, low polishing efficiency, waste of brushes, etc., and achieves obvious effect, The device has the advantages of simple structure and high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

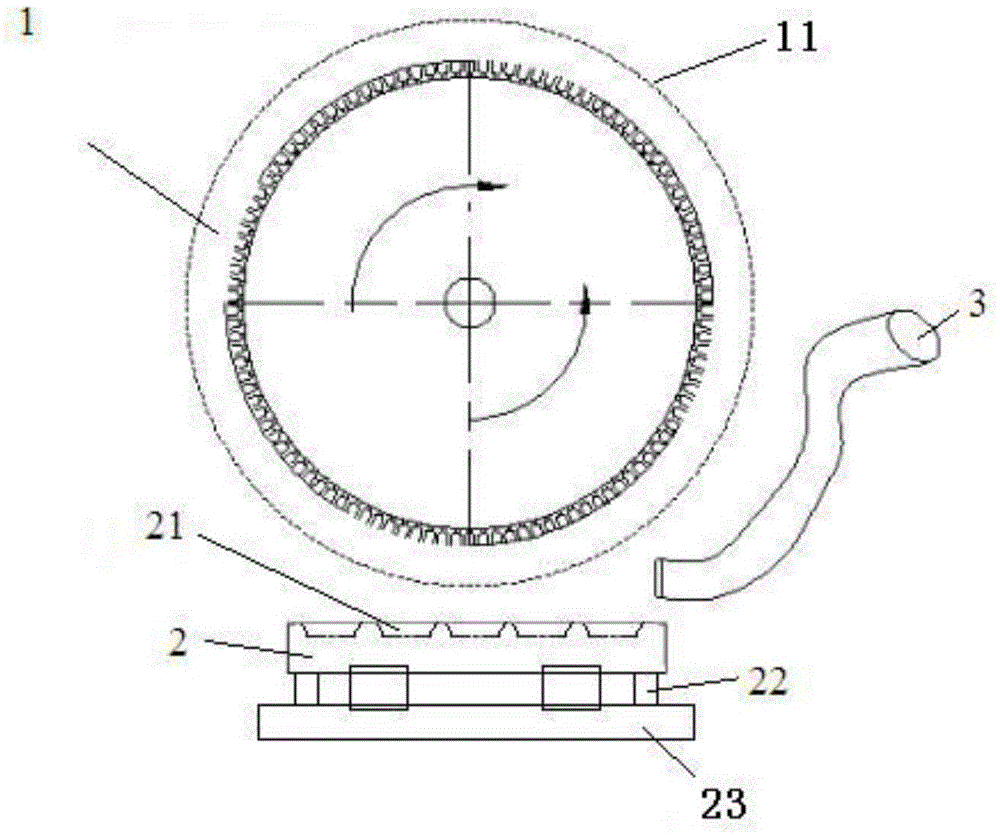

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

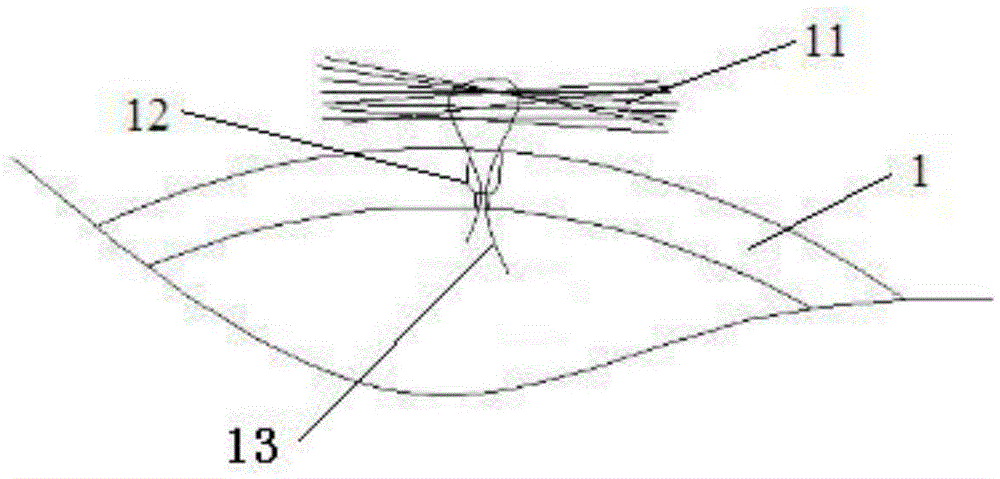

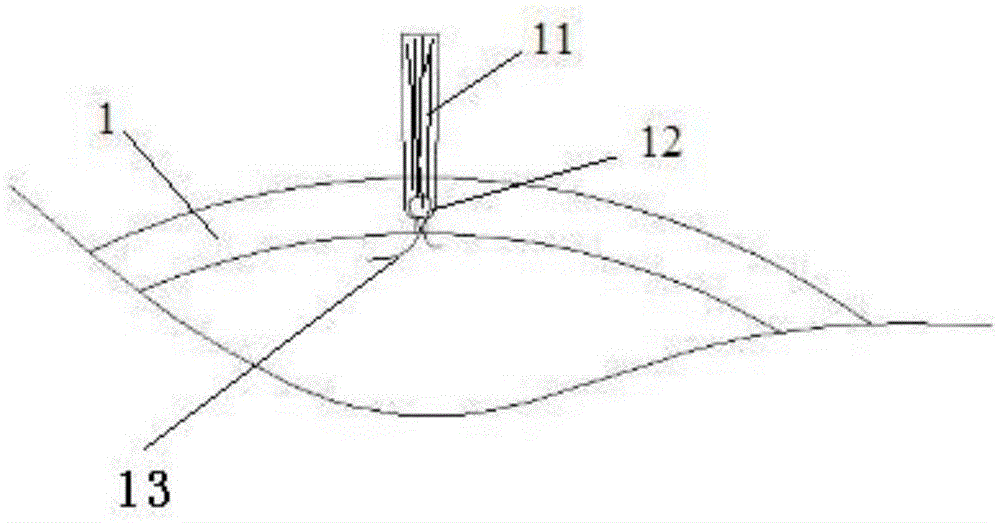

[0028] see Figure 1-A and Figure 1-B A glass polishing brush, the surface of the brush body 1 is densely distributed with bristles 11, the bristles are made of PBT brush filaments, all of the PBT brush filaments are made of PBT resin, and the diameter of the PBT brush filaments is 0.2mm.

[0029] The bristles 11 on the surface of the brush body are distributed in bundles, and each bundle of bristles 11 is formed by weaving a bundle of bristles after being folded and bundled in half. In the vertical plane of the axial center line, the bristle bundle as a whole is perpendicular to the polishing surface of the glass workpiece to be polished during polishing.

[0030] In this embodiment, the length of the bristles before folding in half is 50mm, and the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com