Antistaling agent of plant juice and its preparing process

A preservative and juice technology, applied in the field of plant juice preservative and preparation thereof, can solve the problems of adverse effects on human health, deteriorating aroma and taste, softening and browning of fruit peel, etc., and achieves low cost, easy acquisition, and functional effects. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

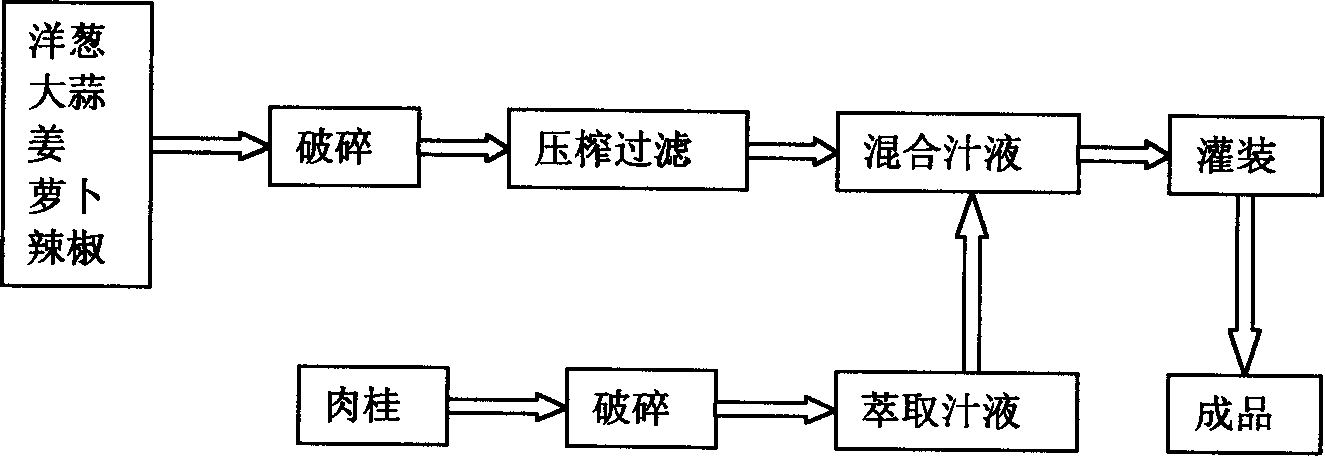

[0037] The raw material of the plant juice preservative can be made from the following components: 50% of garlic; 15% of onion; 12% of ginger; 8% of pepper; 10% of radish; The process of utilizing the above-mentioned raw materials to prepare this plant juice preservative is as follows: figure 1 As shown, the specific steps are as follows: (1) After cleaning the onion, garlic, ginger, radish, and pepper, prepare the portions according to the above ratio and mix them evenly; (2) Use a crusher to crush the mixture into smaller particles; (3) squeeze and filter the crushed material mixture with a press to obtain the mixed juice of the above-mentioned various components; (4) crush the bark and leaves of cinnamon, add water to extract the juice; (5) mix the cinnamon juice with the above-mentioned The juice of multiple components is stirred and mixed evenly with a mixer; (6) filled and packaged into a finished product by a filling machine.

Embodiment 2

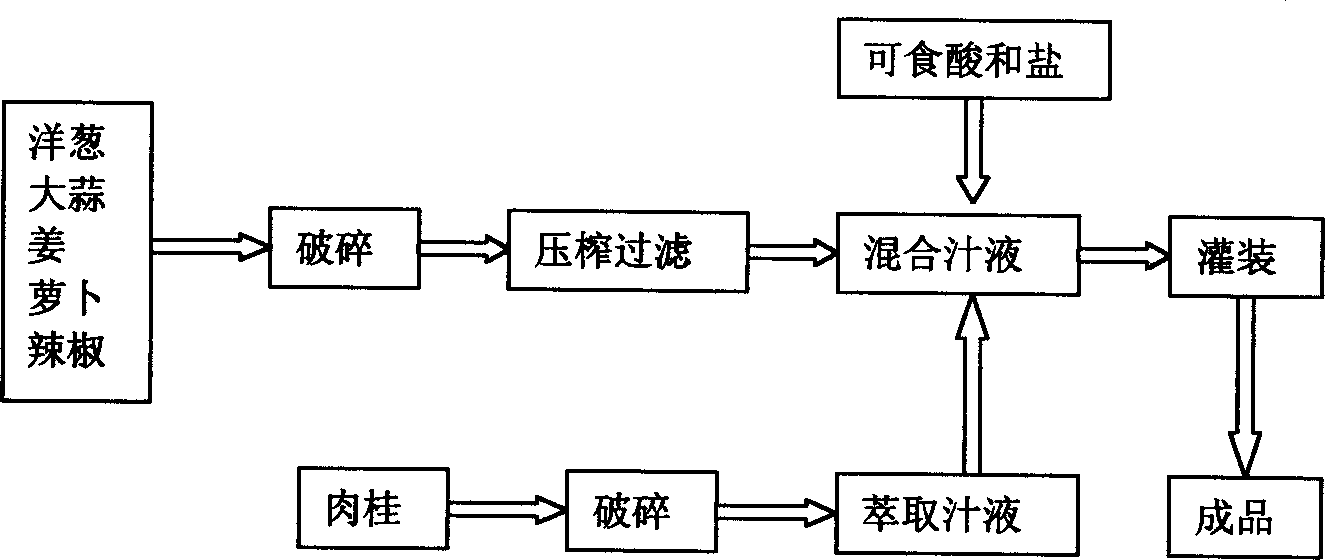

[0039] The raw materials of the plant juice preservative can be made from the following components: 20% garlic; 30% onion; 15% ginger; 5% pepper; 15% radish; 10% cinnamon; 1% malic acid; 0.4% citric acid; acetic acid 2%; 0.5% lactic acid; 0.1% L-ascorbic acid; 1% salt; the above ratios are percentages by weight. The process of utilizing the above-mentioned raw materials to prepare this plant juice preservative is as follows: figure 2 Shown, concrete process is identical with embodiment 1 except following steps: add malic acid, citric acid, acetic acid, Lactic acid, L-ascorbic acid, salt and stir to mix well.

Embodiment 3

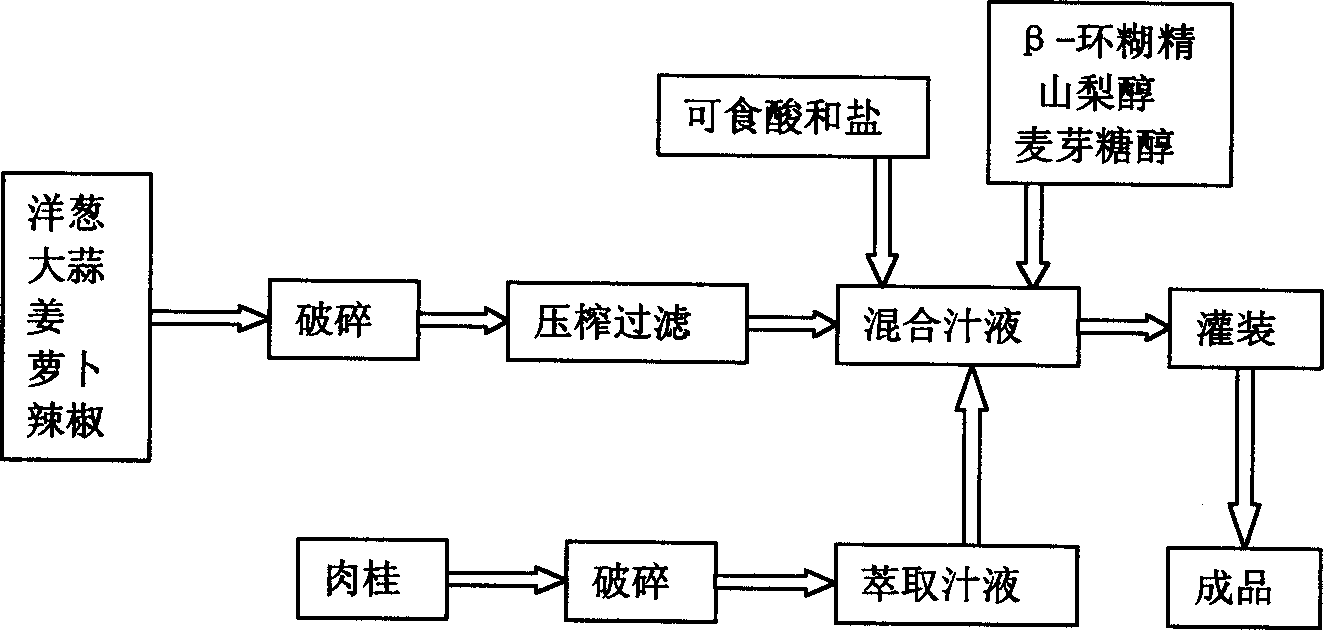

[0041] The raw materials of the plant juice preservative can be made from the following components: 20% garlic; 30% onion; 15% ginger; 5% pepper; 15% radish; 10% cinnamon; 1% malic acid; 0.5% citric acid; acetic acid 0.5%; 0.5% lactic acid; 0.1% L-ascorbic acid; 1% salt; 0.5% β-cyclodextrin; 0.5% sorbitol; The process of utilizing the above-mentioned raw materials to prepare this plant juice preservative is as follows: image 3 Shown, concrete process is identical with embodiment 2 except following steps: when the juice of onion, garlic, ginger, radish, capsicum, cinnamon is mixed with malic acid, citric acid, acetic acid, lactic acid, L-ascorbic acid, salt, press Add β-cyclodextrin, sorbitol, and maltitol to the above component ratio and stir to mix evenly.

[0042] The effect of utilizing this plant juice preservative to carry out fresh-keeping is described below with examples.

[0043] 1. Fruit preservation

[0044] (1) Preserved lychees

[0045] Use 8 to 9 mature lyche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com