Control system and method for concrete raw material mixture ratio

A control system and concrete technology, applied in the directions of mixing operation control, mixing operation control device, batching and batching instrument, etc., can solve the problem of affecting the efficiency of mixing and management, unable to realize automatic control of concrete, and inconvenient for data system management and analysis, etc. problems, to achieve the effect of improving the quality of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

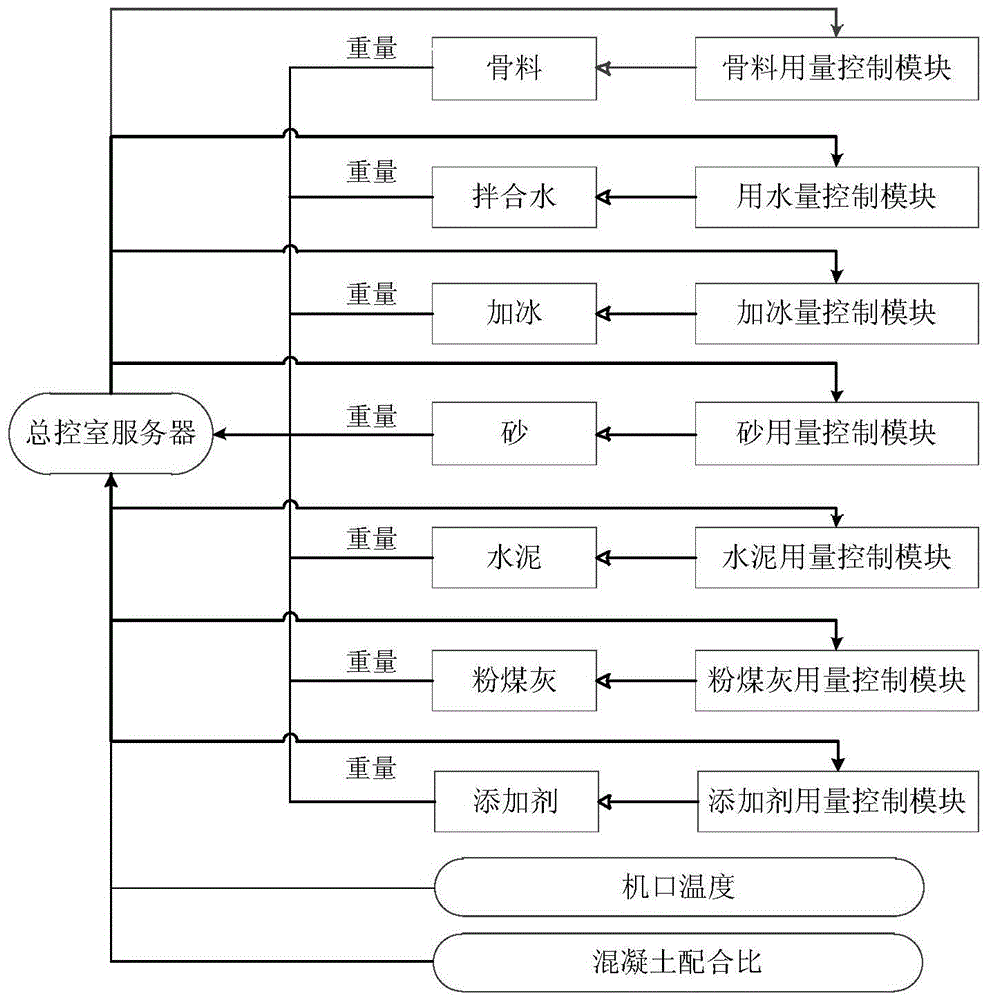

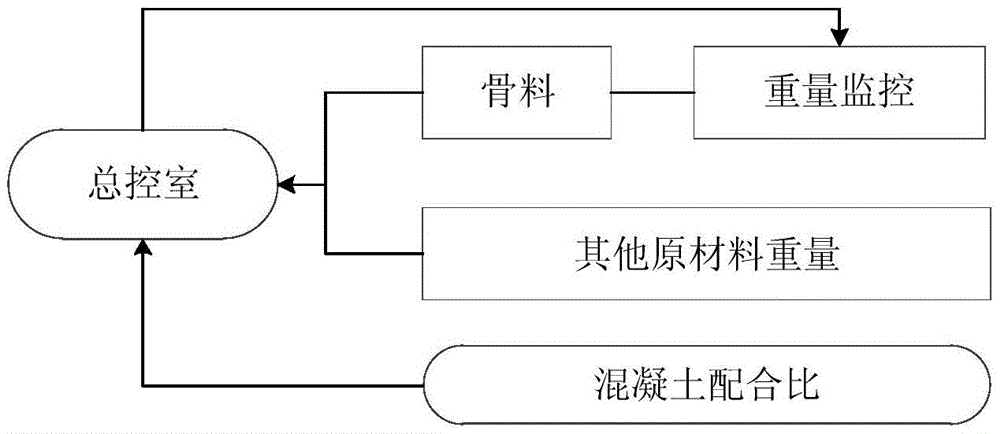

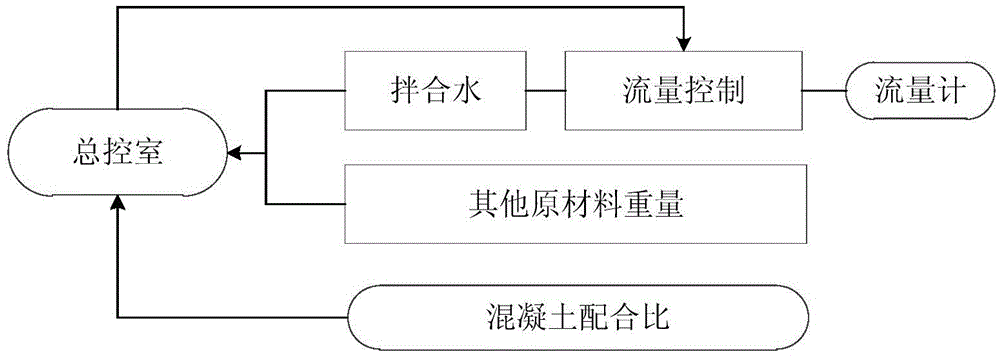

[0022] like figure 1 As shown, the control system for the ratio of raw materials for concrete includes a control module for aggregate consumption, a control module for water consumption in concrete, a control module for adding ice, a control module for sand consumption, a control module for cement consumption, a control module for fly ash consumption, Additive dosage control module, master control room server; aggregate dosage control module, concrete water consumption control module, ice addition control module, sand dosage control module, cement dosage control module, fly ash dosage control module, additive dosage control module and The server in the main control room communicates in real time through the network, and the server in the main control room provides mix ratio information to these modules according to the results of the previous concrete performance test, so as to realize the intelligent control of the amount of raw materials in the concrete mixing process.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com