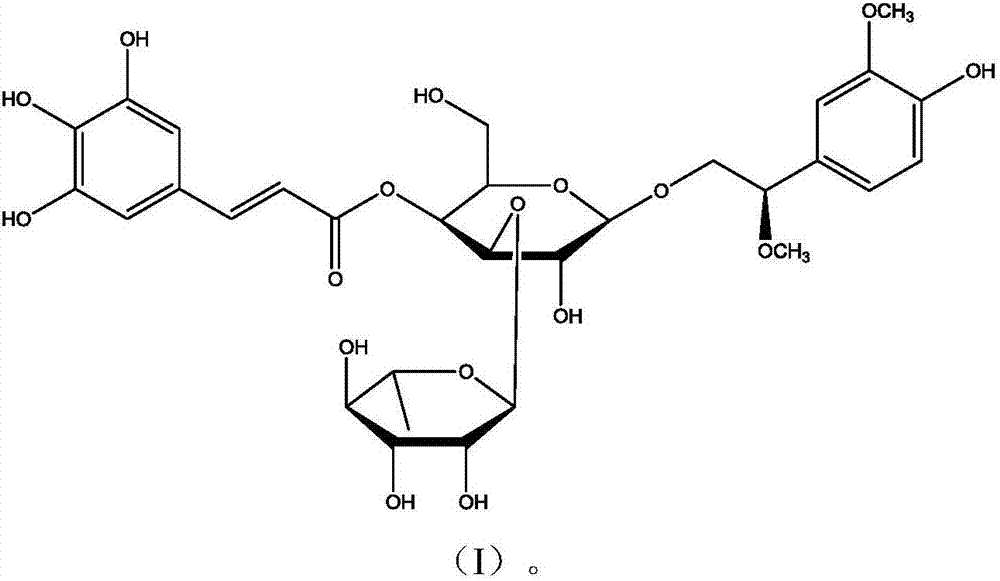

Phenylethanol glycosides extracted from thistle and its preparation method and use

A technology of phenylethanol glycosides and compounds, which is applied in the field of natural medicinal chemistry, can solve the problem of insufficient penetration of thistle, and achieve the effects of remarkable curative effect, convenient operation and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

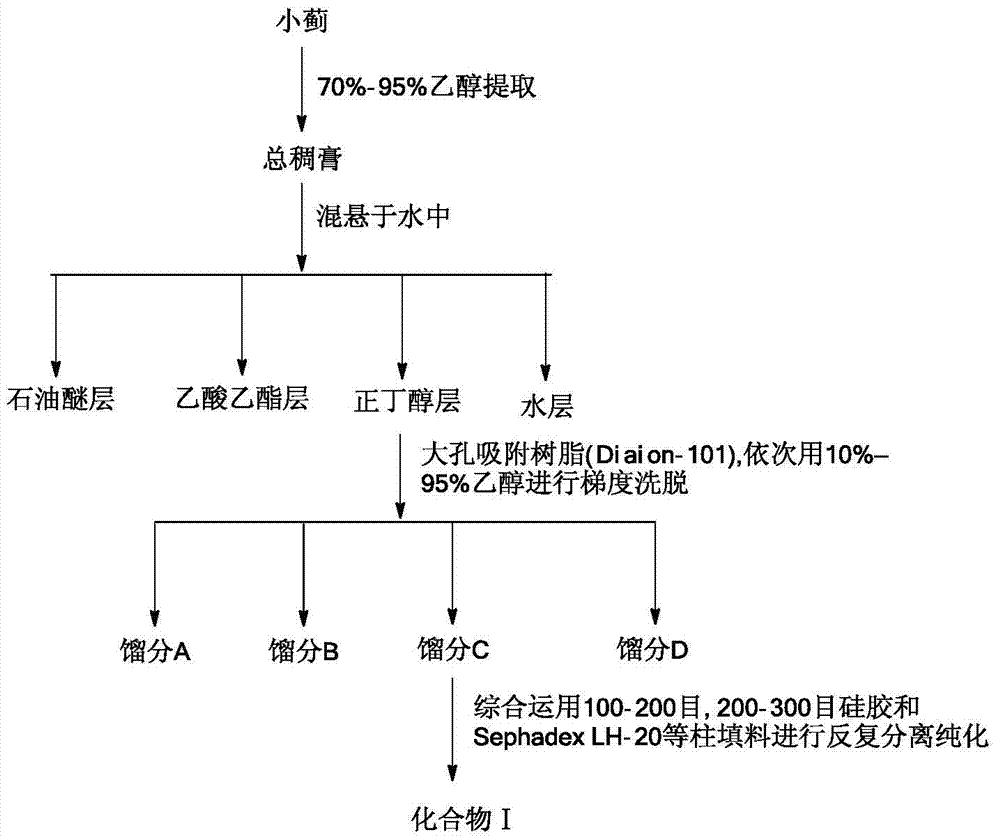

[0024] Such as figure 1 As shown, take 8kg of dry whole plant of thistle as raw material, extract twice with 70% ethanol (18L×2), each time for 1.5 hours, filter the extract, combine the filtrates, concentrate under reduced pressure at 40°C until alcohol-free Taste obtains total thick cream 0.9kg. Suspend the obtained total thick paste and water in an appropriate amount of water according to the volume ratio of 1:1, and sequentially extract 3 times with petroleum ether, ethyl acetate and n-butanol to obtain 83.5 g of petroleum ether partial extracts, and ethyl acetate partial extractions. Product 185.7g, n-butanol partial extract 238.1g. According to the pharmacological screening results of the previous extracts, the extract from the n-butanol fraction was determined to be the active fraction. Put 238.1g of n-butanol extract on a macroporous adsorption resin column (Diaion-101), and sequentially use 10%, 25%, 45%, 95% ethanol for gradient elution to obtain A, B, C, D four ki...

Embodiment 2

[0026] Take 12 kg of dry whole plant of thistle as raw material, extract 3 times with 85% ethanol (18L×3), 2 hours each time, filter the extract, combine the filtrates, concentrate under reduced pressure at 45°C until there is no alcohol smell to obtain the total Thick paste 1.3kg. Suspend the obtained total thick paste and water in an appropriate amount of water according to the volume ratio of 1:1, and sequentially extract 4 times with petroleum ether, ethyl acetate and n-butanol to obtain 110.2 g of petroleum ether partial extracts, and 110.2 g of partial extractions with ethyl acetate. Product 202.5g, n-butanol partial extract 280.4g. According to the pharmacological screening results of the previous extracts, it was determined that the n-butanol part of the extract was the active site. Put 280.4g of n-butanol extract on a macroporous adsorption resin column (Diaion-101), and sequentially use 15%, 30%, 60%, 95% ethanol for gradient elution to obtain A, B, C, D four kinds ...

Embodiment 3

[0028] Take 15kg dried whole plant of thistle as raw material, extract 4 times with 95% ethanol (20L×4), 3 hours each time, filter the extract, combine the filtrates, concentrate under reduced pressure at 48°C until no alcohol smell is obtained The total thick cream is 1.6kg. The obtained total thick paste and water were suspended in an appropriate amount of water according to the volume ratio of 1:1, and were extracted 4 times with petroleum ether, ethyl acetate and n-butanol successively to obtain 156.4 g of petroleum ether partial extracts, and 156.4 g of ethyl acetate partial extractions. Product 254.2g, n-butanol partial extract 304.7g. According to the pharmacological screening results of the previous crude extract, it was determined that the extract from the n-butanol fraction was the active fraction. Put 304.7g of n-butanol partial extract on macroporous adsorption resin column (Diaion-101), and carry out gradient elution with 20%, 40%, 70%, 95% ethanol in sequence to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com