Super amphiphilic molecule emulsifier with responsiveness and emulsion and preparation method thereof

An amphiphilic molecule and emulsifier technology, which is applied in the field of responsive super-amphiphilic molecule emulsifier and its emulsion, can solve the problems of high cost, product pollution, influence of demulsifier system, etc., and achieves low cost and wide adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] D230 and oleic acid are magnetically stirred and mixed at a ratio of 1:2.5 by weight to form a super amphiphilic emulsifier. Based on 100 parts by weight, take 49.5 parts of pure water, 1 part of emulsifier and 49.5 parts of crude oil. Put the emulsifier, the water phase and the oil phase together into the reactor, and stir them evenly with magnetic force to form an emulsion.

[0018] The stability and demulsification effect of the prepared emulsion were investigated respectively according to the following methods:

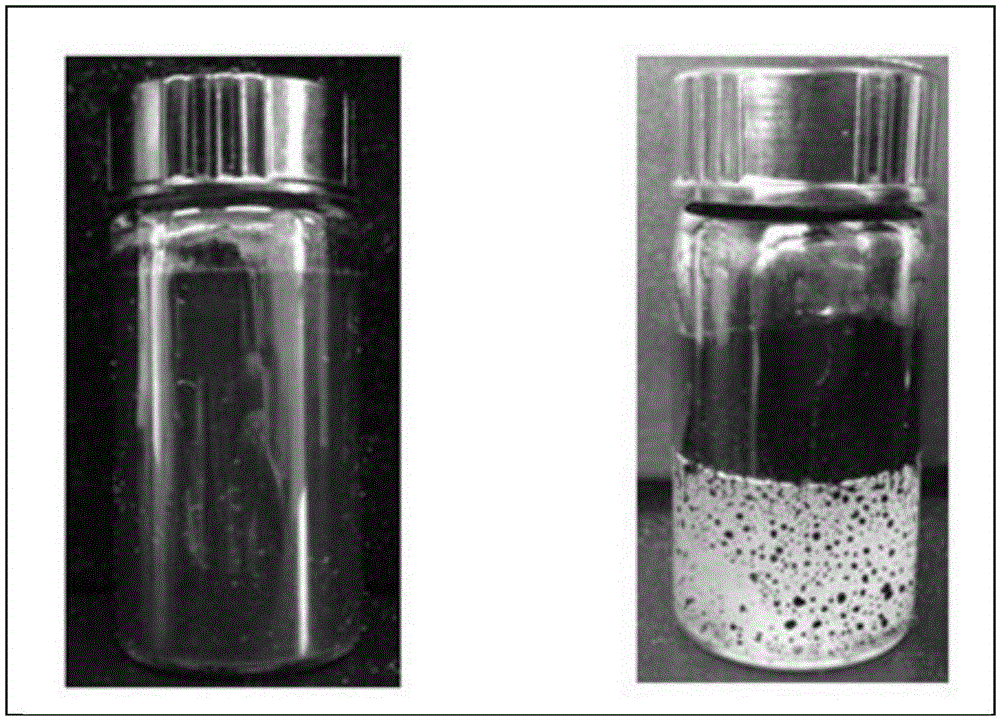

[0019] 1. Stability evaluation: Let the emulsion stand at room temperature for 24 hours, and observe whether there is a clear layering in the appearance. Observations: Stable emulsion, no separation for 24 hours, see figure 1 left image in .

[0020] 2. Evaluation of demulsification effect: Introduce CO into the freshly prepared emulsion 2 Alternatively, add a hydrochloric acid aqueous solution, an aqueous nitric acid aqueous solution, an aqueous sulfur...

Embodiment 2

[0025] Mix D400 and stearic acid with magnetic stirring at a weight ratio of 1:1.4 to form an emulsifier. Based on 100 parts by weight, take 80 parts of pure water, 1 part of emulsifier and 19 parts of paraffin oil. Put the emulsifier, water phase and paraffin oil together into the reactor, and mix evenly under stirring to form an emulsion.

[0026] Investigate the stability and demulsification effect of emulsion in the mode of embodiment 1, the results are as follows:

[0027] 1. The emulsion is stable and does not separate within 24 hours;

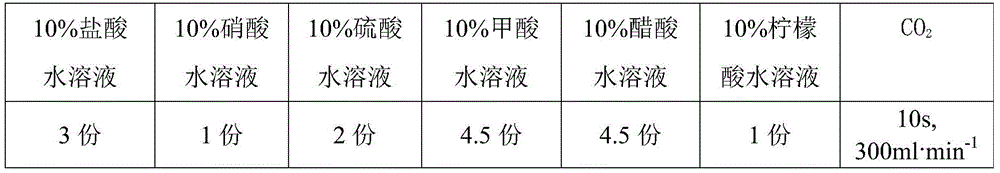

[0028] 2. See the table below for the amount (one of them) of the acidic substance added during the oil-water separation of per 100 parts by weight of the emulsion.

[0029]

Embodiment 3

[0031] Mix D400 and capric acid with magnetic stirring at a weight ratio of 1:0.86 to form an emulsifier. Based on 100 parts by weight, take 60 parts of pure water, 2 parts of emulsifier, 19 parts of crude oil and 19 parts of paraffin oil, and mix the crude oil and paraffin oil at a weight ratio of 1:1 to form a thin crude oil. Put the emulsifier, the water phase and the mixed crude oil into the reactor, and mix them evenly under stirring to form an emulsion.

[0032] Investigate the stability and demulsification effect of emulsion in the mode of embodiment 1, the results are as follows:

[0033] 1. The emulsion is stable and does not separate within 24 hours;

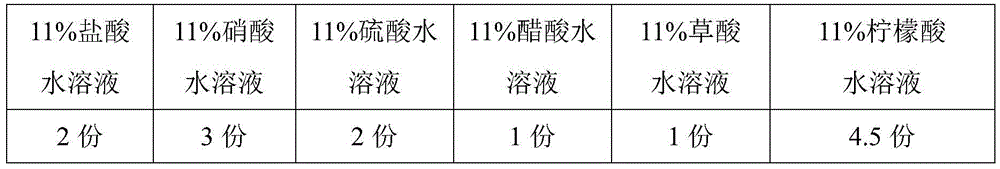

[0034] 2. See the table below for the amount (one of them) of the acidic substance added during the oil-water separation of per 100 parts by weight of the emulsion.

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com