A kind of self-generated foam micellar acid solution of water injection well

A technology of self-generated foam and micellar acid, which is applied in the directions of drilling compositions, chemical instruments and methods, can solve the problems of secondary damage to the formation, incomplete flowback, and short validity period of measures, and achieves high flowback efficiency. , reduce secondary damage, and the effect of the acidification process is complete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

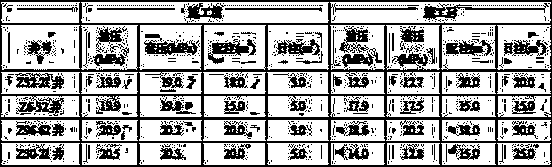

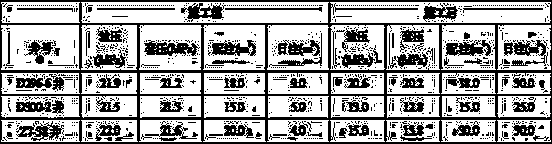

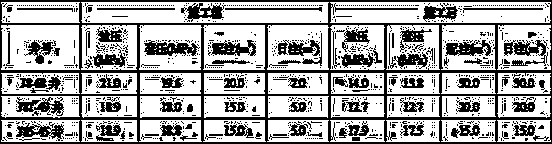

Image

Examples

Embodiment 1

[0023] A self-generated foam micellar acid solution for water injection wells is characterized in that it is composed of the following mass percentage components:

[0024] Hydrochloric acid: 15.0%~20.0%;

[0025] Hydrofluoric acid: 3.0% to 5.0%;

[0026] Foaming agent: 0.5% to 2.0%;

[0027] Foam stabilizer: 0.5% to 1.0%;

[0028] Micellar agent: 10.0%~15.0%;

[0029] Corrosion inhibitor: 0.5% to 1.0%;

[0030] Clay stabilizer: 2.0% to 10.0%;

[0031] Iron ion stabilizer: 2.0% to 10.0%;

[0032] Drainage aid: 2.0% to 10.0%;

[0033] The rest is distilled water.

[0034] In the work, the foamy micellar acid solution provided by this embodiment, in the construction process, the construction shows that the average water injection pressure drops by 4.5MPa, the single well water absorption capacity increases by 25m3 / d, the effective rate of the measures is 100.0%, and the effective period of the measures is 200 days The above shows that the self-generating foam micellar aci...

Embodiment 2

[0036] A water injection well self-generated foam micellar acid solution is prepared according to the following steps:

[0037] 1) Add concentrated hydrochloric acid with a mass percentage of 15.0% to the acid-resistant container. The concentration of the concentrated hydrochloric acid is 31%, without diluting with water;

[0038] 2) Add 1.0% mass percentage of corrosion inhibitor, 1.0% demulsifier, 10.0% clay stabilizer, 10.0% iron ion stabilizer, 10.0% drainage aid composition;

[0039] 3) Add 3% hydrofluoric acid to the container in step 2), and the concentration of the hydrofluoric acid is 40%;

[0040] 4) Add distilled water to the container in step 3), and stir well until the acid solution in the container is fully mixed with the reagent;

[0041] 5) To the container in step 4), add a foaming agent with a mass percentage of 2.0%. The foaming agent is composed of benzalkonium chloride, fusel alcohol, secondary octanol, and sodium lauryl sulfate in a ratio of 1:1: Prepa...

Embodiment 3

[0052] A water injection well self-generated foam micellar acid solution is prepared according to the following steps:

[0053] 1) Add concentrated hydrochloric acid with a mass percentage of 20.0% to the acid-resistant container, the concentration of the concentrated hydrochloric acid is 31%, without diluting with water;

[0054] 2) Add 0.5% mass percentage of corrosion inhibitor, 0.5% demulsifier, 2.0% clay stabilizer, 2.0% iron ion stabilizer, 2.0% drainage aid composition;

[0055] 3) Add 5% hydrofluoric acid to the container in step 2), and the concentration of the hydrofluoric acid is 40%;

[0056] 4) Add distilled water to the container in step 3), and stir well until the acid solution in the container is fully mixed with the reagent;

[0057] 5) To the container in step 4), add a foaming agent with a mass percentage of 0.5%. The foaming agent is composed of benzalkonium chloride, fusel alcohol, secondary octanol, and sodium lauryl sulfate at a ratio of 1:1: Prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com