Steel spring surface full-decarburization nondestructive testing method

A non-destructive testing and decarburization technology, which is applied in the direction of measuring devices, preparation of test samples, optical testing of flaws/defects, etc., can solve the problem of damaging the spring structure, increasing the cost of testing and testing, and cannot accurately detect the decarburization of the spring surface, etc. problems, to save high costs, improve the thermal processing process, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

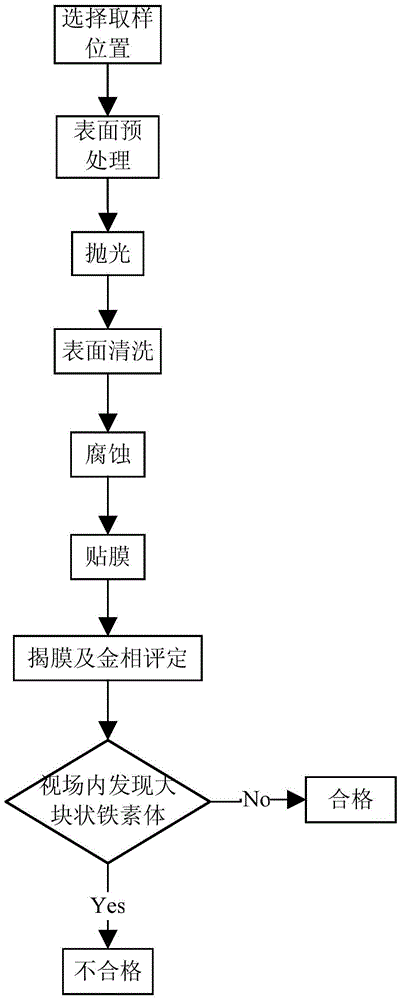

[0029] Such as figure 1 Shown is the flow chart of the detection method of the present invention. The non-destructive testing method for the full decarburization of the steel spring surface in this embodiment, the steps include:

[0030] In the first step, the sampling position of the in-service spring is selected as the exposed outer circular surface as the sampling site;

[0031] The second step is to use a paint remover to remove the paint on the surface of the spring;

[0032] The third step is to use a polishing agent such as 3 μm abrasive paste to polish the surface to expose the basic metal surface; the fourth step is to use acetone solution to clean the metal surface;

[0033] The fifth step is to use 4% volume concentration of nitric acid alcohol to corrode the surface to be tested, and the corrosion time is 6s;

[0034] Step 6: Paste the AC paper on the corroded surface. To ensure a complete replica, wet the AC paper and the corroded surface with acetone;

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com