Sodium silicate composite self-repairing concrete structure and preparation method thereof

A technology of concrete structure and sodium silicate, which is applied in the field of sodium silicate composite self-repairing concrete structure and its preparation, can solve the problems of high repair cost, labor and material resources, and the failure of small width cracks to achieve the repair effect. Improve mechanical properties and waterproof and impermeable properties, reduce high costs, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

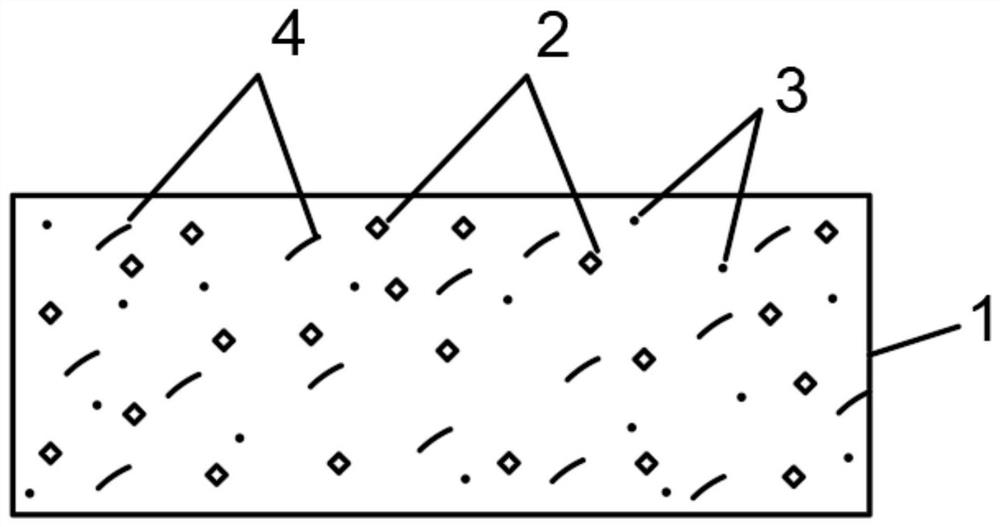

[0034] Such as Figure 1 ~ 2 As shown, a sodium silicate composite self-repair concrete structure comprising a concrete member 1, and a sodium silicate repair agent 2 is incorporated into a silicate repair agent 2, penetrating crystalline material 3 and PVA fiber 4.

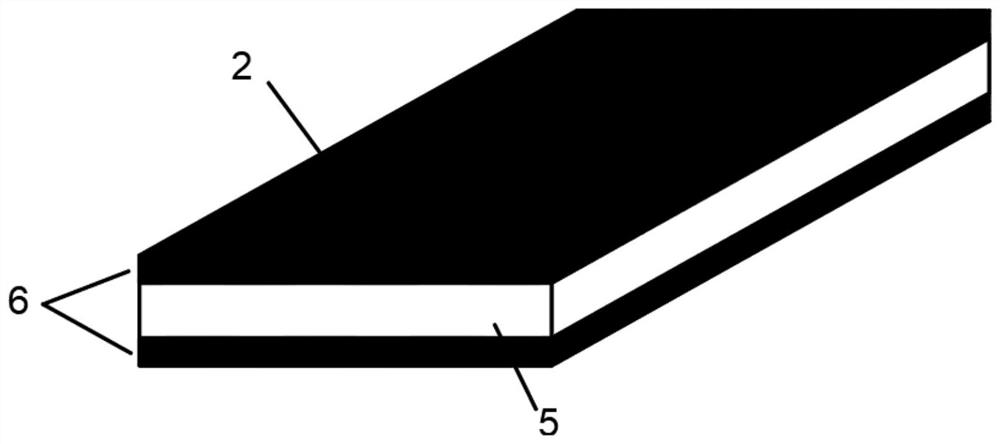

[0035] The sodium silicate repair agent 2 is a sheet-like solid having a diameter of about 5 to 7 mm, and sodium sodium-acid repair agent 2 is a composite structure, see figure 2 The silicate repair agent 2 includes an epoxy resin layer made of an outer two layers of an epoxy resin 6 and an anhydrous silicate layer made of anhydrous silicate particles 5 between the two cyclic oxygen resin layers. .

[0036] The penetration crystalline material 3 of this embodiment employs the active silicon penetration of the active silicon produced by Guangzhou Shu Shield Waterproof Material Co., Ltd., the appearance is gray powder, the density is 2000 ~ 2100kg / m 3 .

[0037] The PVA fiber 4 of the present embodiment uses high-str...

Embodiment 2

[0039] The same is substantially the same as the examples, and the present embodiment also provides a method of preparing self-repair concrete, including steps:

[0040] Step 1: Making sodium silicate repair agents;

[0041] Step 2: Design concrete mix ratio, determine sodium silicate repair agent 2, penetrate crystalline material 3 and PVA fiber 4 duct;

[0042] Step 3: Sodium sodium sal Sodium hydrate is uniformly incorporated into the concrete in the form of a aggregate, and the permeable crystalline material 3 and the PVA fiber 4 are incorporated into concrete;

[0043] Step 4: Pour the concrete on the concrete member and maintain the shape.

[0044] In this embodiment, the specific steps of the production of sodium silicate repair agents are as follows:

[0045] Step 1.1: Scratch the transparent tape segment, soak it in an epoxy resin;

[0046] Step 1.2: Someth sodium anhydrous silicate is sprinkled on the side of the tape to adhere the epoxy resin, the thickness is about 1 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com