Vacuum system

A technology of vacuum system and vacuum pump, applied in the field of vacuum system, can solve the problem that the chamber cannot continue to work, and achieve the effect of improving the operating time and increasing the production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

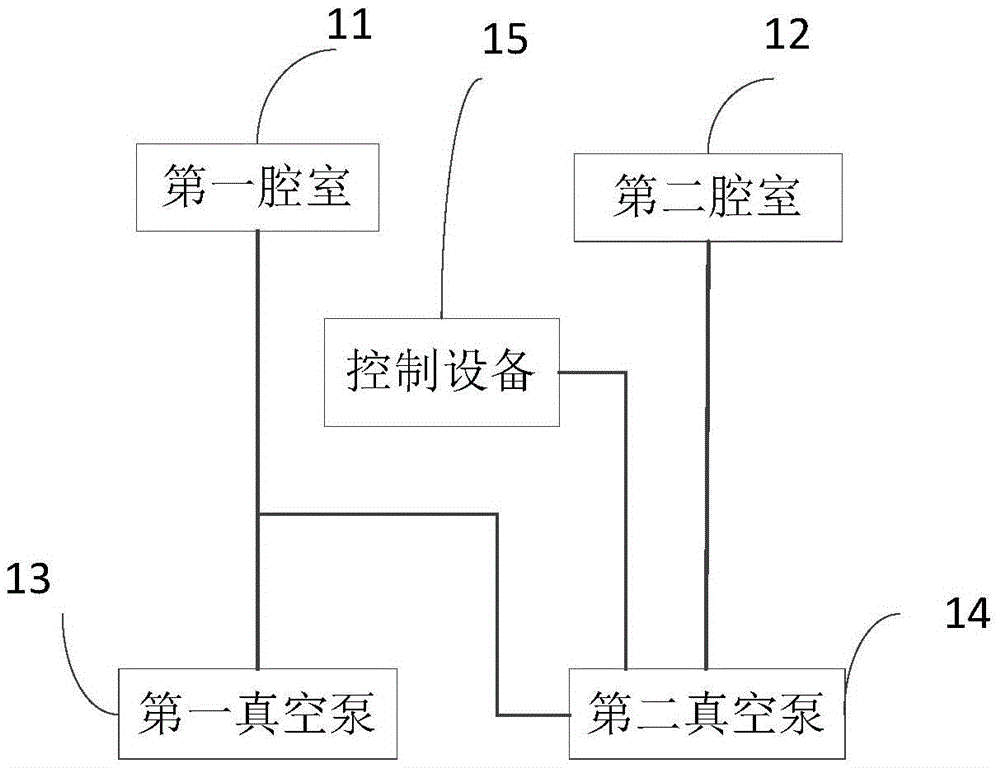

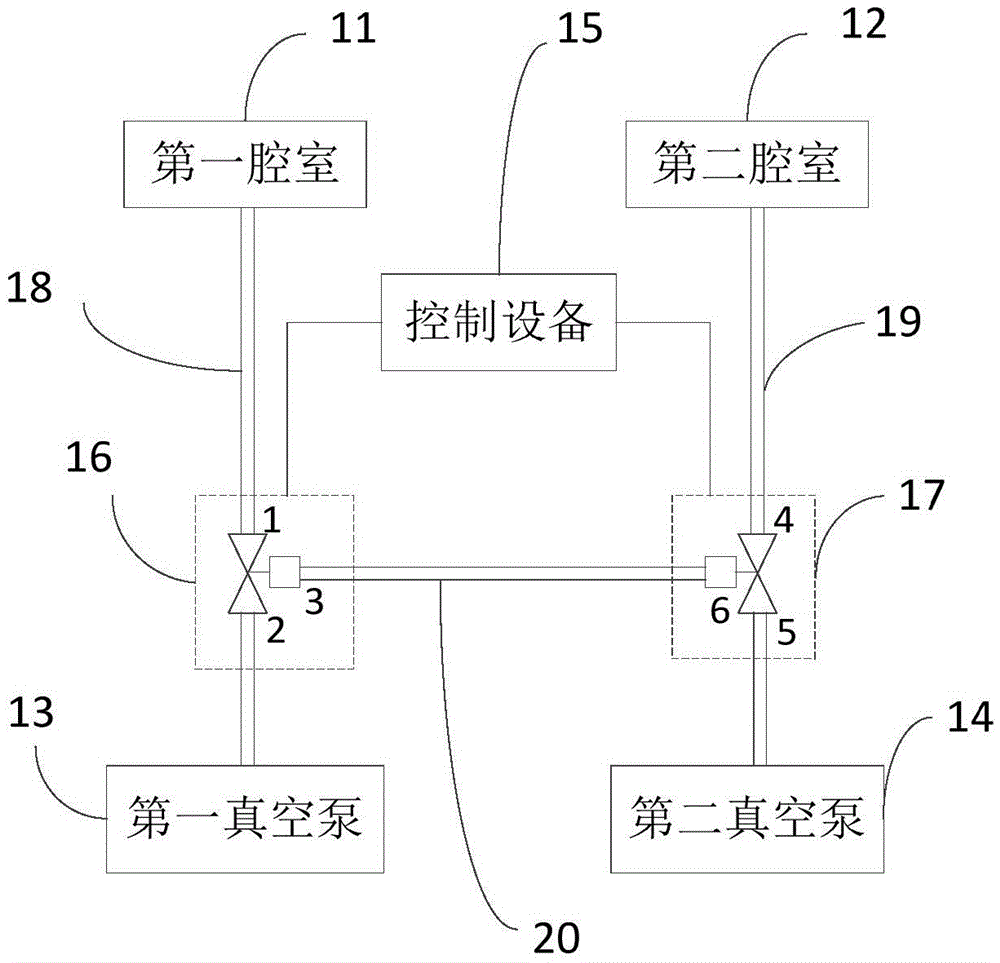

[0023] Such as figure 1 As shown, Embodiment 1 of the vacuum system of the present invention includes:

[0024] The first chamber 11, the second chamber 12, the first vacuum pump 13, the second vacuum pump 14 and the control device 15;

[0025] The first vacuum pump 13 is connected to the first chamber 11 for evacuating the first chamber 11 under normal operating conditions, and the second vacuum pump 14 is connected to the second chamber 12 for evacuating the second chamber under normal operating conditions. 12 vacuumize, the first chamber 11 is further connected with the second vacuum pump 14;

[0026] The control device 15 is used to use the second vacuum pump 14 to simultaneously evacuate the first chamber 11 and the second chamber 12 when the first vacuum pump 13 is abnormally shut down.

[0027] Under normal working conditions, the first chamber 11 maintains a communication state with the first vacuum pump 13, and is connected but not communicated with the second vacuu...

Embodiment 2

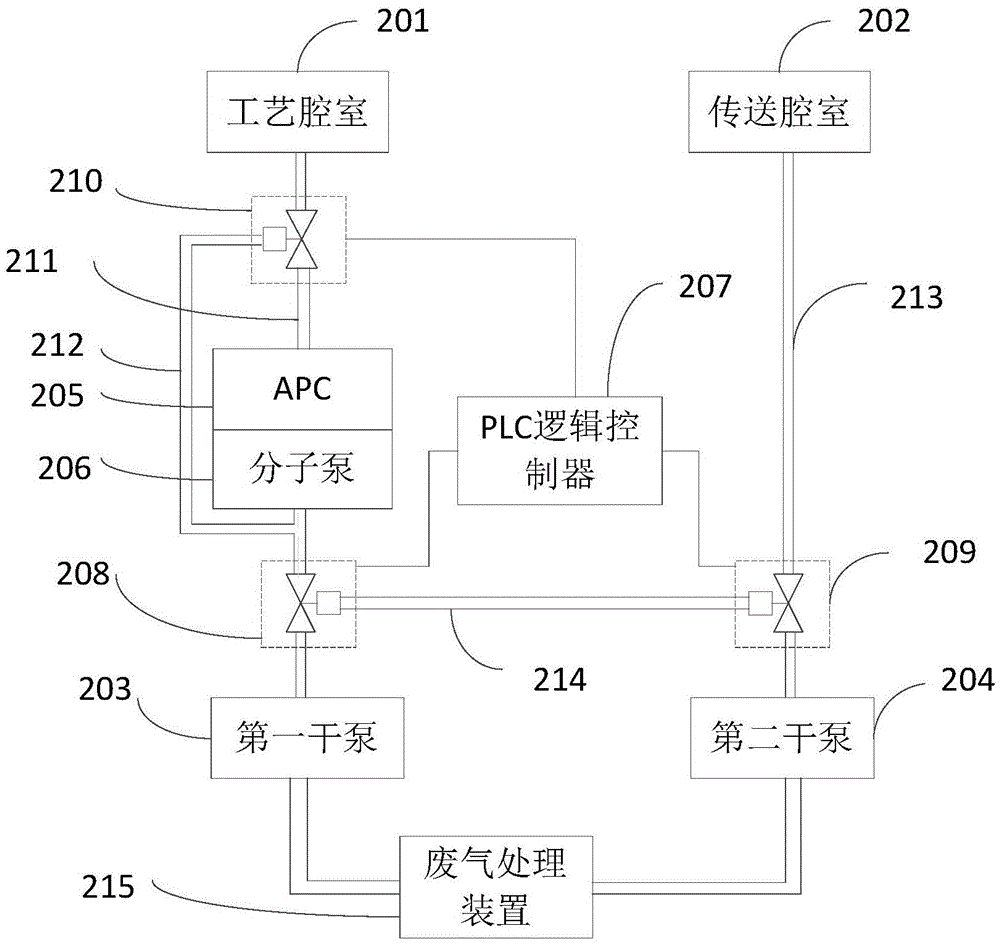

[0037] Such as image 3 As shown, the second embodiment of the vacuum system of the present invention is a dry etching vacuum system, including: a first chamber 201, a second chamber 202, a first vacuum pump 203, a second vacuum pump 204 and a control device 207, wherein the first The chamber 201 is a process chamber 201, the second chamber 202 is a transfer chamber 202, the first vacuum pump 203 is a first dry mechanical pump (dry pump for short) 203, and the second vacuum pump 204 is a second dry pump 204. The device 207 is a PLC logic controller 207 .

[0038] The process chamber 201 and the transfer chamber 202 are connected in series. During production, the raw materials are transported to the process chamber 201 through the transfer chamber 202 for processing, and the samples processed in the process chamber 201 are transferred out through the transfer chamber 202 . A first pipeline 211 is connected between the process chamber 201 and the first dry pump 203. The first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com