Current collector for metal secondary battery negative electrode and preparation method and application for current collector

A secondary battery and current collector technology, applied in the field of electrochemical power sources, can solve the problems of introducing impurities, weak interaction between carbon nanotubes and substrates, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of three-dimensional porous materials decorated with carbon nanospheres

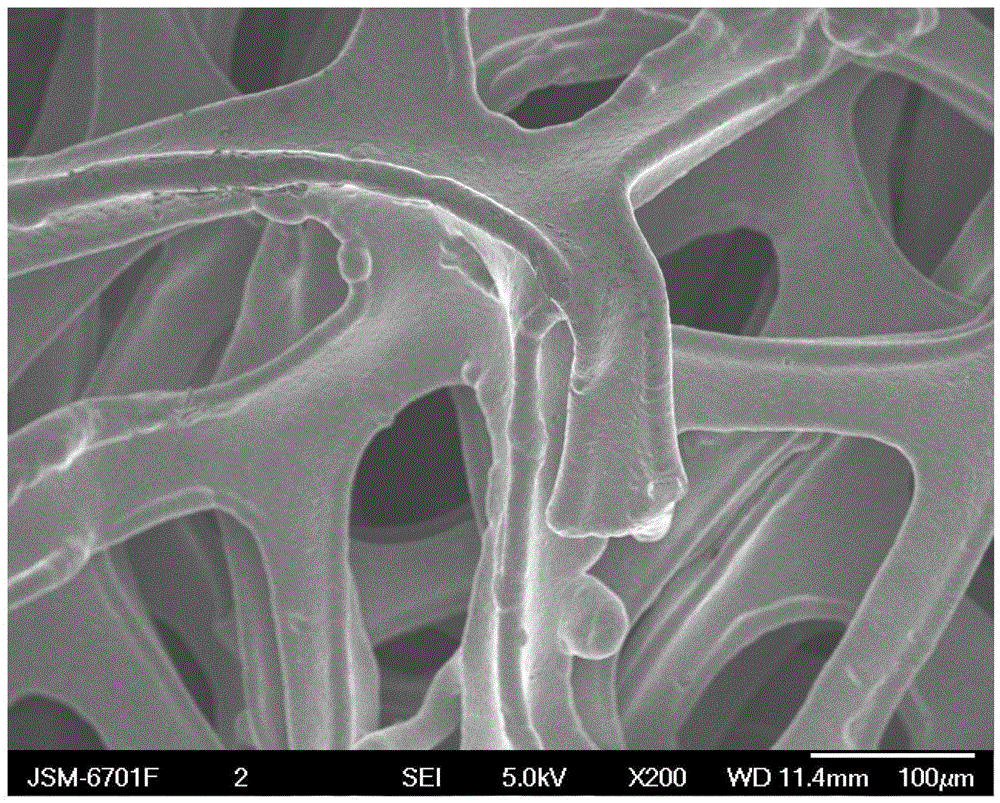

[0032] (1) Wash the commercial nickel foam, dry it, and heat it at 900°C under H 2 / Ar mixed reducing atmosphere annealed for 30min to remove the oxide layer on the surface of nickel foam. From figure 1 The scanning electron micrograph of the nickel foam can see the three-dimensional porous structure with a pore size of 50-50 μm.

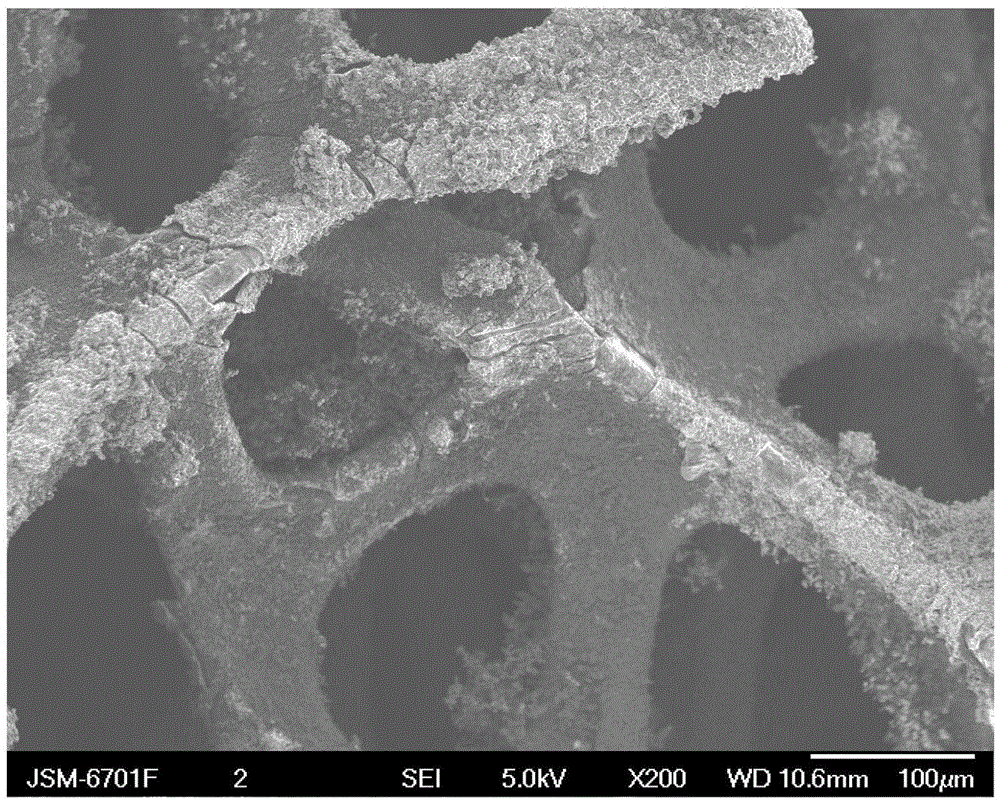

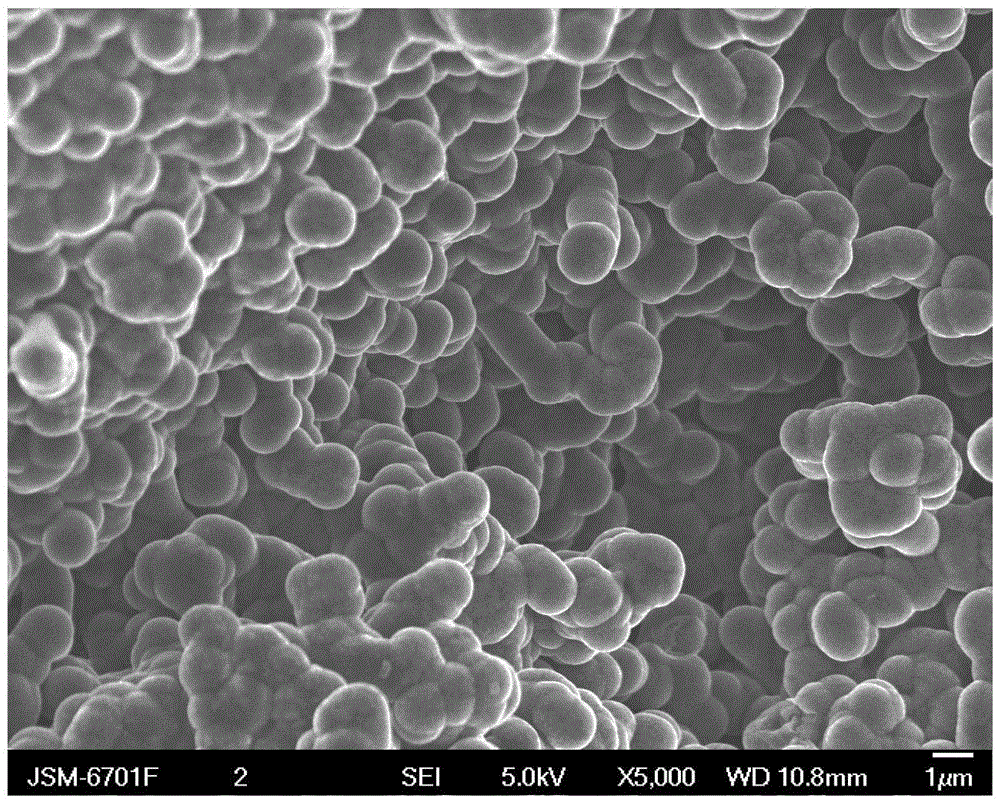

[0033] (2) Place the annealed nickel foam in a CVD tube furnace, 2 h 2Carrier gas, heat up at a rate of 10°C / min, the flow ratio of hydrocarbon gas to carrier gas is 400sccm:25sccm, deposit at 900°C for 5min, and the deposited carbon mass is 1-10mg / cm 2 . From figure 2 The scanning electron micrograph of can clearly see that described carbon is deposited on the framework of porous nickel foam, image 3 for figure 2 The magnification of the scanning electron microscope photo, from which it can be seen that the deposited carbon morphology is a sp...

Embodiment 2

[0043] The difference from Example 1 is that (1) prepare a three-dimensional porous current collector modified by carbon nanospheres, and the hydrocarbon gas is ethylene (C 2 h 4 ), C 2 h 4 The flow ratio of gas to carrier gas is 340sccm:50sccm, deposited at 950°C for 4 minutes, and the distribution of deposited carbon is relatively uniform, with a mass of 1-6mg / cm 2 , the diameter of carbon spheres is 1100-1400nm. Deposit 2mAhcm -2 The deposition / stripping efficiency of Li was 85% for the first time and reached 98.5% after 2 cycles.

Embodiment 3

[0045] The difference from Example 1 is that (1) prepare a three-dimensional porous current collector modified by carbon nanospheres, the hydrocarbon gas is toluene, the flow ratio of toluene to carrier gas is 320sccm:25sccm, deposited at 1000°C for 10min, after characterization, The deposited carbon is evenly distributed, with a mass of 1-10mg / cm 2 , the diameter of carbon spheres is 1000-1300nm. Deposit 2mAhcm -2 The deposition / stripping efficiency of Li was 82% for the first time after adding Li, and reached 98% after 2 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com