Substrate of anti-CAF (Conductive Anodic Filament) printed circuit board and manufacturing method thereof

A technology for printed circuit boards and manufacturing methods, which is applied in the direction of printed circuit manufacturing, printed circuits, printed circuit components, etc., and can solve problems such as product short circuit failure, glass fiber layer breakage or poor bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

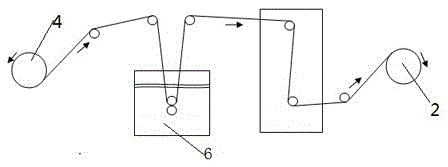

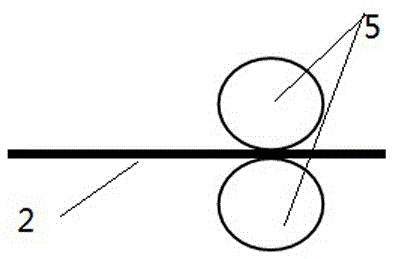

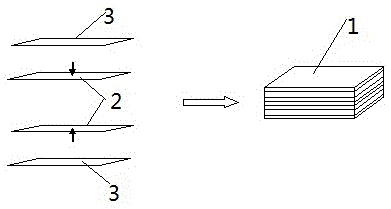

[0026] The substrate 1 of the anti-CAF printed circuit board, the prepreg 2, and the metal layer 3 covering the upper and lower positions of the prepreg 2, as a preference, the metal layer 3 is copper foil; the prepreg 2 is a fragmented prepreg 2. Fragmented prepreg 2 is at least one layer. Fragmented prepreg 2 consists of broken glass yarn and epoxy resin wrapping the broken glass yarn. The length of the broken glass yarn is less than the hole-to-hole gap distance on the printed circuit board. Fragmented prepreg 2 reduces the influence of the spinning effect of warp and weft yarns in the glass cloth, so that the size of the substrate can expand and shrink more uniformly, because the more uniform the glass plus resin structure, the more it can make the traditional PCB production process such as drilling, plated through The hole process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com