Brushless wiper motor

A wiper and sensor technology, which is applied in the field of brushless wiper motors, can solve the problems of loud sliding contact between the brush and the commutator, unstable operation of the wiper motor, and restrictions on the miniaturization of the wiper motor, so as to achieve light weight, shortened size, Realize the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, a first embodiment of the present invention will be described in detail with reference to the drawings.

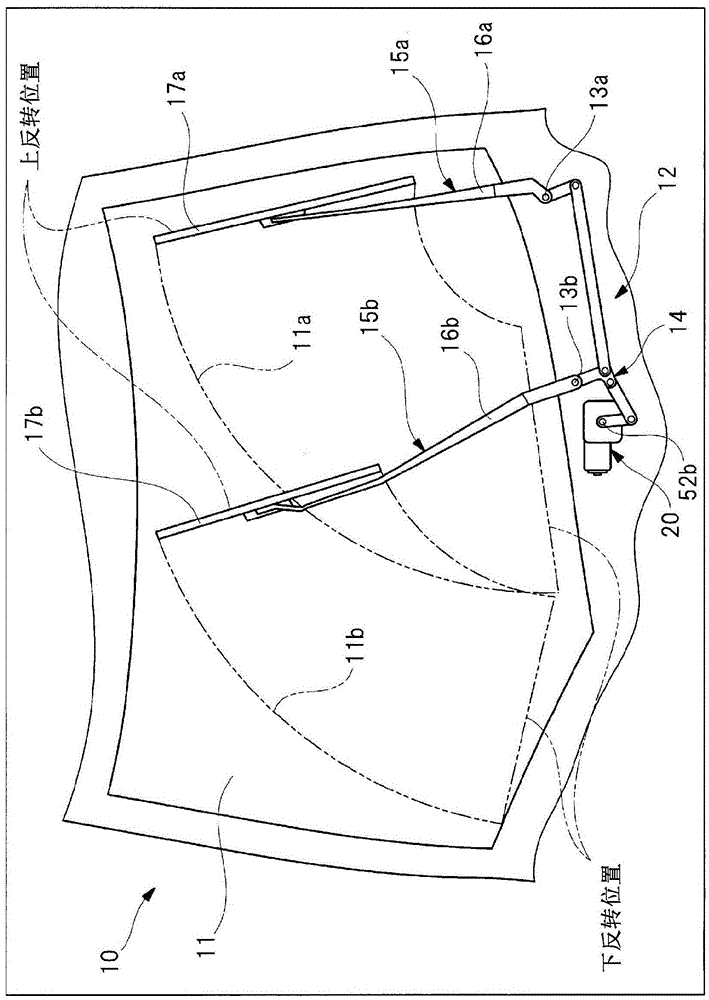

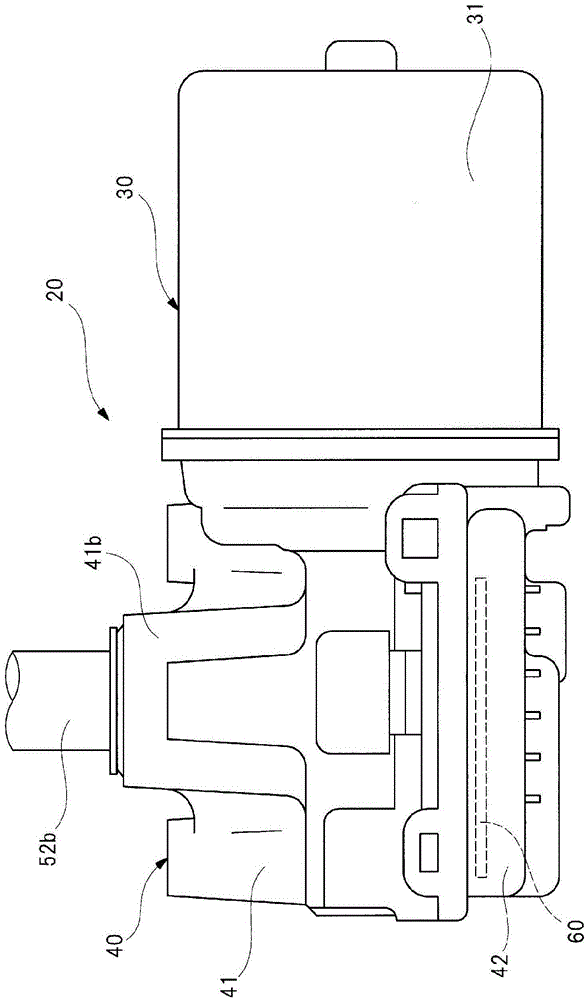

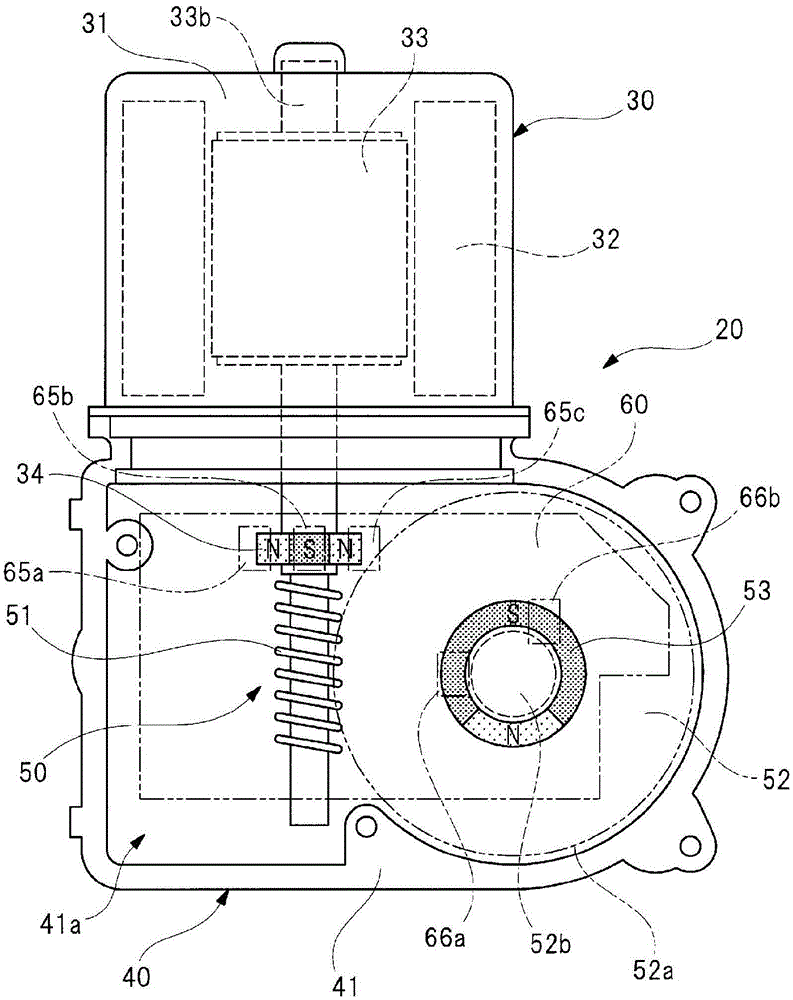

[0041] figure 1 To show a vehicle installation diagram of a wiper device having a wiper motor of the present invention, figure 2 to show figure 1 The appearance diagram of the wiper motor, image 3 for will figure 2 The bottom view of the state where the gear cover is removed from the gear case, Figure 4 It is an explanatory diagram illustrating the detailed structure of the rotor and the rotating shaft, Figure 5 (a) is along Figure 4 The cross-sectional view of the A-A line, (b) is along the Figure 4 The cross-sectional view of the B-B line of (c) is a cross-sectional view showing a modified example of the magnet for the rotating shaft, Figure 6 A block diagram illustrating the electrical system of the wiper motor.

[0042] Such as figure 1 As shown, a windshield 11 is attached to a vehicle 10 such as an automobile, and a wiper device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com