Manufacturing method of magnesium alloy cardiovascular stent, stent and perform of stent

A manufacturing method, magnesium alloy technology, applied in the direction of brackets, etc., can solve the problems of high cost and complex process, and achieve the effect of reducing production cost, simplifying process and avoiding complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

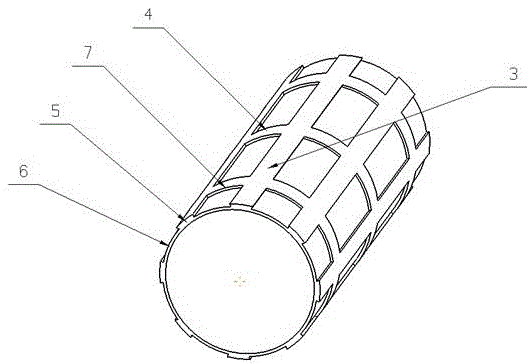

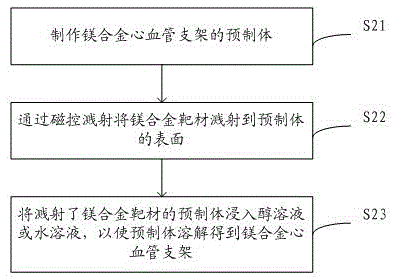

[0025] Such as figure 1 As shown, it is a structural diagram of a prefabricated body for making a magnesium alloy cardiovascular stent proposed by an embodiment of the present invention, the prefabricated body includes a stent body and an inner lining 6; the stent body is a tubular body with a mesh structure; the tubular body The mesh structure is composed of axial ribs 3 and beam ribs 4; the section 5 of the axial ribs 3 is trapezoidal; the side 7 of the beam ribs is inclined to the inside of the tubular body; the inner lining 6 is a tubular body placed inside the tubular body.

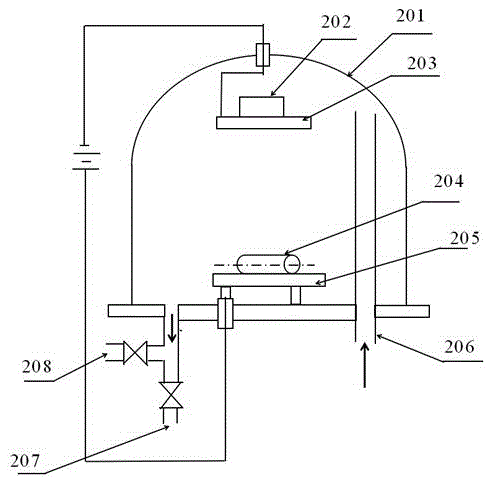

[0026] The prefabricated body is prepared based on 3D printing technology; the inner diameter of the stent body is smaller than the inner diameter of the final formed magnesium alloy cardiovascular stent by two magnetron sputtering magnesium al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com