A kind of naringin controlled-release capsule and its preparation method

A technology of glycoside controlled-release capsules and naringin, which is applied in capsule delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., and can solve the problems of slow onset of action, large fluctuations in blood drug concentration, and frequent doses of ordinary sustained-release tablets. and other problems, to achieve the effect of simple technical method, less frequency of taking medicine, and easy access to excipients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

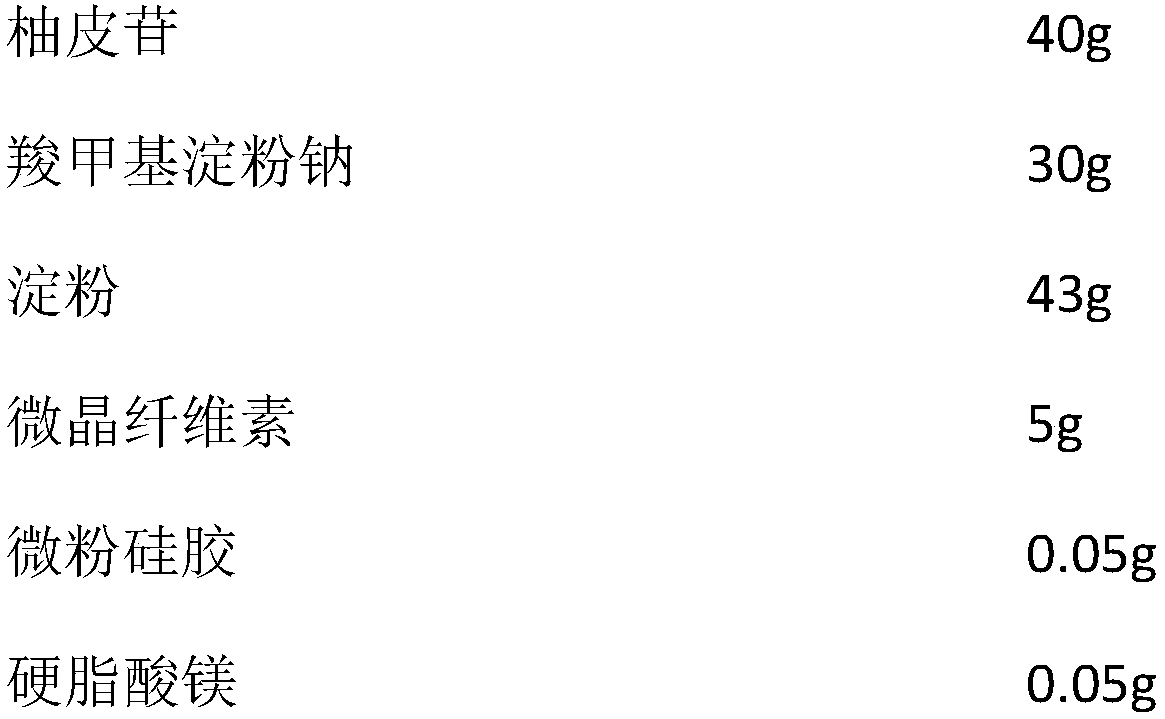

[0019]

[0020] Mix the first four of the above materials evenly, granulate with 10% corn starch slurry, dry, add lubricant micropowder silica gel and magnesium stearate after granulation, and press the content of 120 mg of naringin per tablet into tablets.

[0021]

[0022] Mix the first four of the above materials evenly, granulate with 95% ethanol, dry, add lubricant micropowder silica gel and magnesium stearate after granulation, and press 120 mg of naringin per tablet into tablets. The aforementioned two tablets are packed into capsules at a ratio of 1:2. After release measurement, the results show that the release amount of the control capsule is 20% to 30% of the labeled amount in 10 minutes, and the release amount of the released tablet is 35% of the labeled amount in 2 hours, 4 hours, 8 hours, and 12 hours. ~45%, 55~65%, 75~85%, 95% or more, to achieve the purpose of controlled release.

Embodiment 2

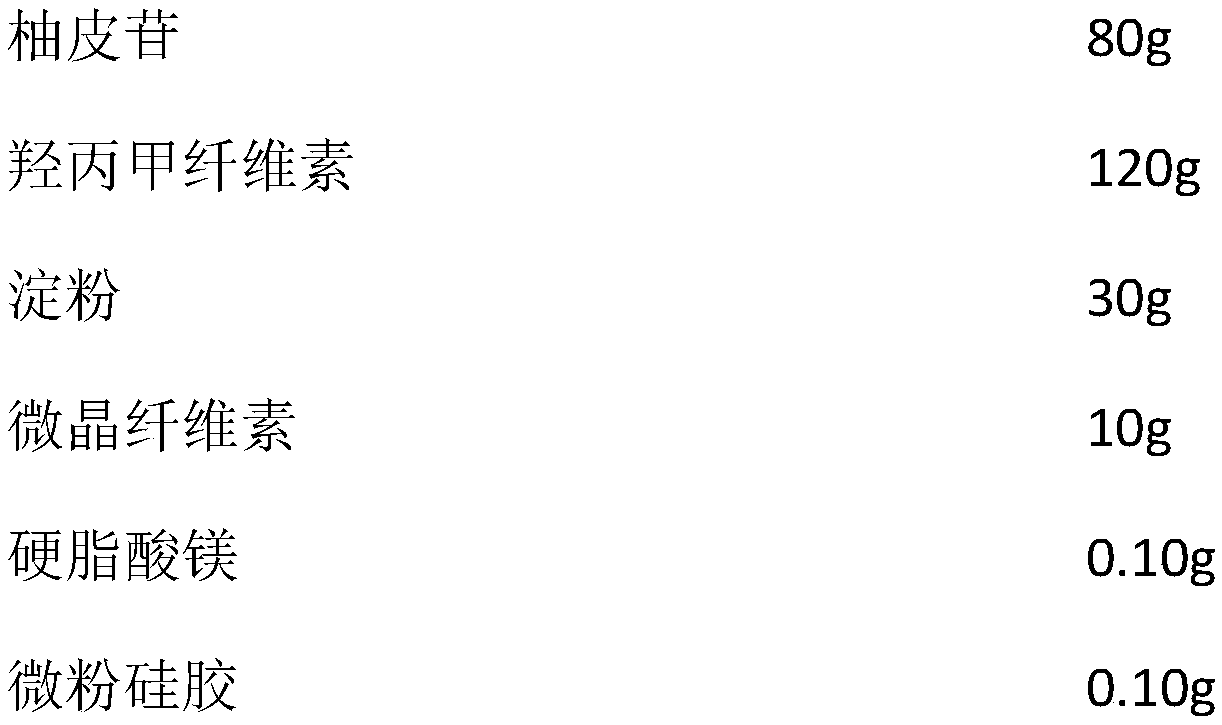

[0024]

[0025] Mix the first four of the above-mentioned materials evenly, granulate with 10% corn starch slurry, dry, add lubricant micropowder silica gel and magnesium stearate after granulation, and compress into tablets according to the content of 120 mg of naringin per tablet.

[0026]

[0027] Mix the first four of the above materials evenly, granulate with 95% ethanol, dry, add lubricant micropowder silica gel and magnesium stearate after granulation, and compress into tablets according to the content of 120 mg of naringin per tablet. The aforementioned two tablets are packed into capsules at a ratio of 1:2. After release measurement, the results show that the release amount of the control capsule is 20% to 30% of the labeled amount in 10 minutes, and the release amount of the released tablet is 35% of the labeled amount in 2 hours, 4 hours, 8 hours, and 12 hours. ~45%, 55~65%, 75~85%, 95% or more, to achieve the purpose of controlled release.

Embodiment 3

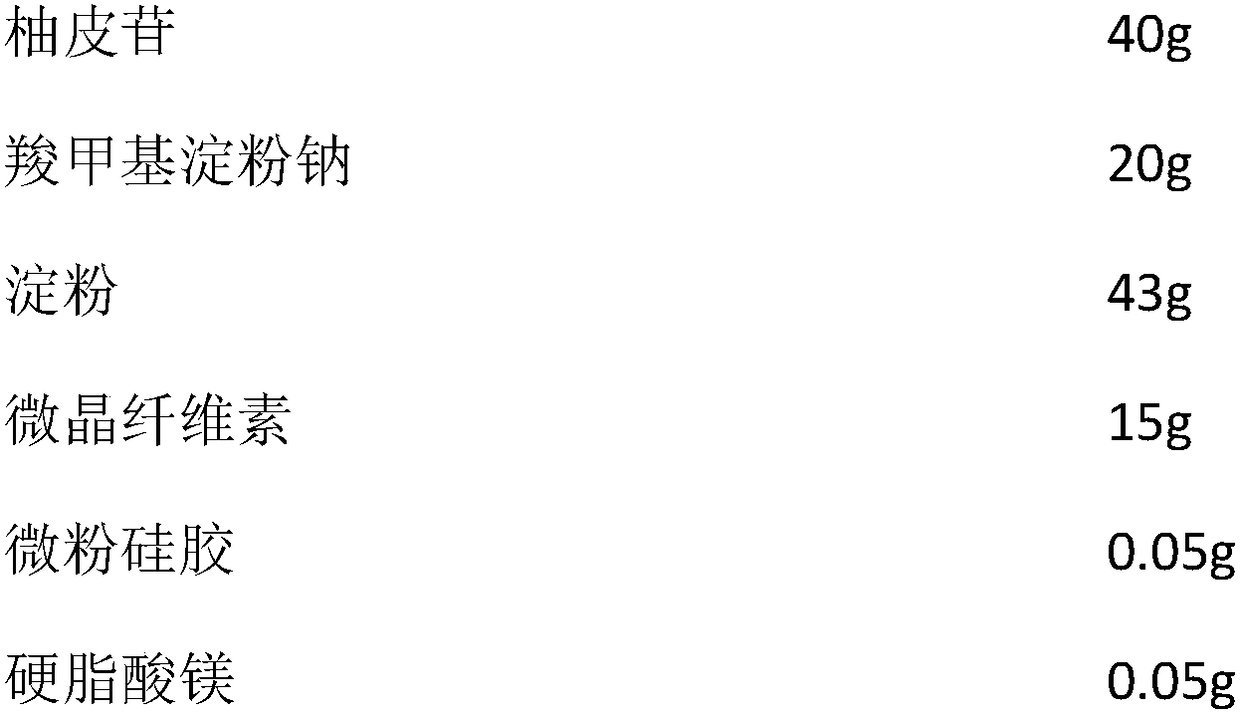

[0029]

[0030] Mix the first four of the above-mentioned materials evenly, granulate with 10% corn starch slurry, dry, add lubricant micropowder silica gel and magnesium stearate after granulation, and compress into tablets according to the content of 120 mg of naringin per tablet.

[0031]

[0032] Mix the first four of the above materials evenly, granulate with 95% ethanol, dry, add lubricant micropowder silica gel and magnesium stearate after granulation, and press 120 mg per tablet into tablets.

[0033] The aforementioned two tablets are packed into capsules at a ratio of 1:2. After release measurement, the results show that the release amount of the control capsule is 20% to 30% of the labeled amount in 10 minutes, and the release amount of the released tablet is 35% of the labeled amount in 2 hours, 4 hours, 8 hours, and 12 hours. ~45%, 55~65%, 75~85%, 95% or more, to achieve the purpose of controlled release.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com