Liquid ammonia dilution apparatus and application method thereof

A dilution device and liquid ammonia technology, applied in the field of liquid ammonia dilution system, can solve the problems of long production cycle, high equipment failure rate, and many equipment, and achieve the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

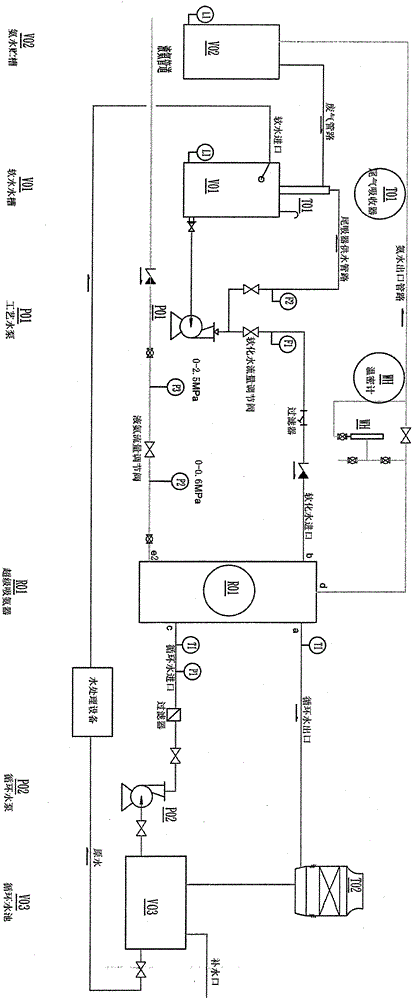

[0033] A liquid ammonia dilution device, including super ammonia absorber R01, cooling tower T02, circulating pool P02, process water pump P01, soft water tank V01, ammonia water storage tank V02, tail gas absorber T01, and water treatment equipment;

[0034] The liquid ammonia flows into the super ammonia absorber through the liquid ammonia pipeline, and the soft water enters the super ammonia absorber from the softened water tank through the softened water inlet, and a certain concentration of industrial ammonia water is directly formed in the super ammonia absorber, and the formed industrial ammonia water is sent through the ammonia water outlet pipeline. to the ammonia storage tank;

[0035]The upper part of the ammonia water storage tank is provided with a waste gas outlet, and the waste gas outlet is connected with the tail gas absorber through the waste gas pipeline, and is used to discharge a small amount of non-condensable gas in the liquid ammonia from the ammonia wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com