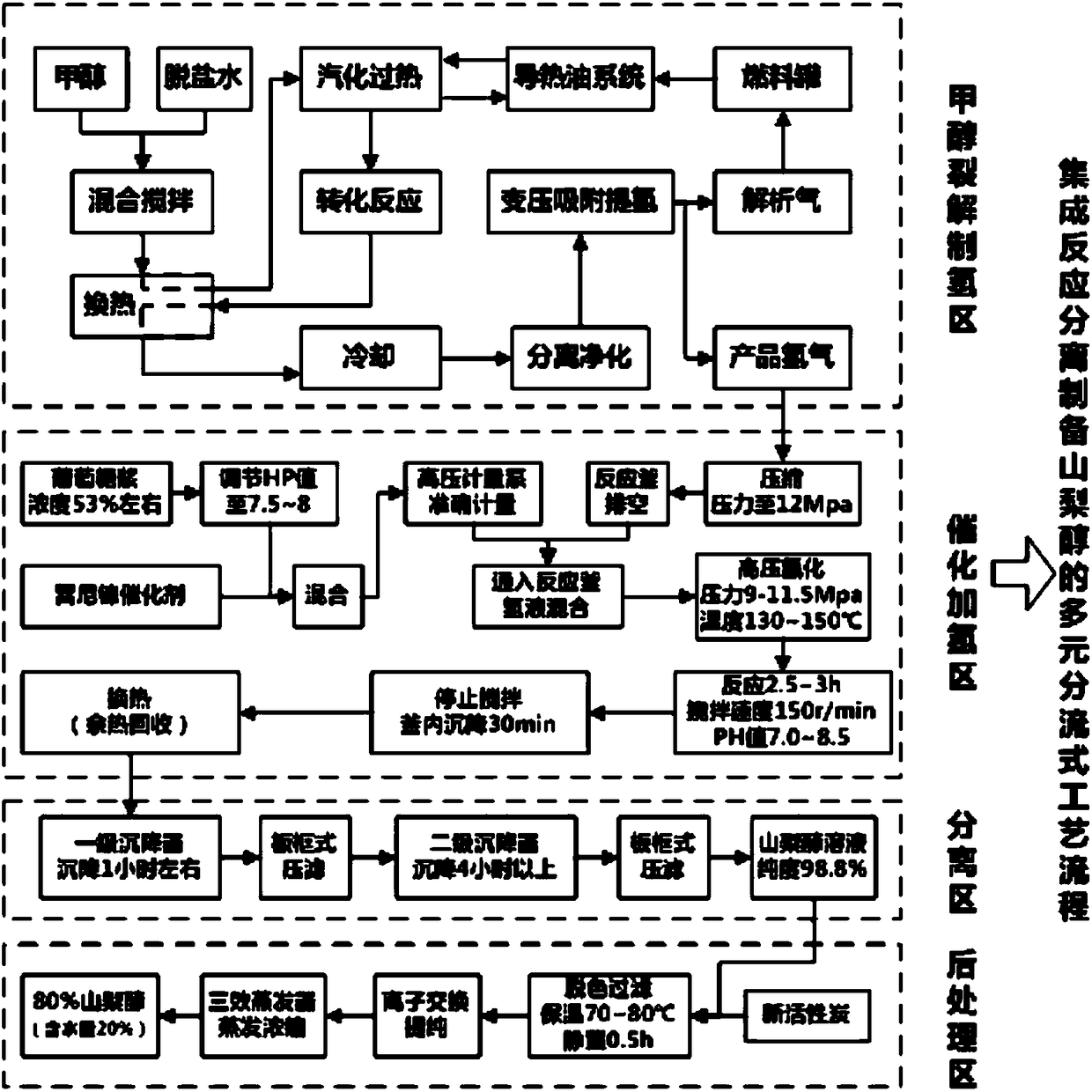

Self-organized split-flow control method and device for preparing sorbitol by integrated reaction separation

A sorbitol and split-flow technology, which is applied in the field of self-organized split-flow control of integrated reaction separation to prepare sorbitol, can solve the problems of intensified side reactions, long production cycle, and increase of the overall production cycle, so as to reduce the production of reaction by-products , prevent side reactions, and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

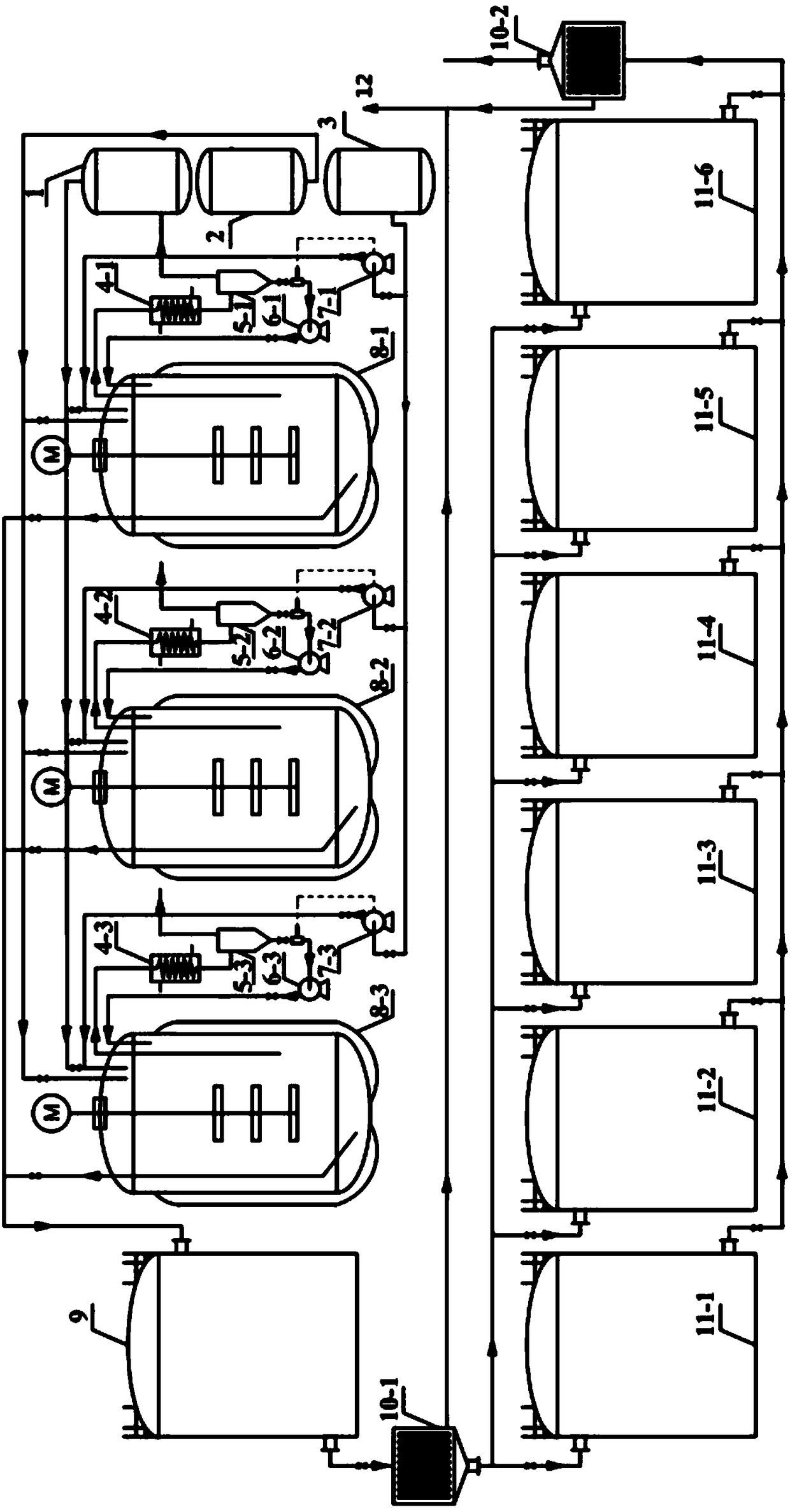

Embodiment 1

[0049] Add catalyst to the reaction kettle group, the amount of catalyst added is 300kg, lay the bottom, after the catalyst is added, close all valves, feed hydrogen into the reaction kettle, wait until the pressure in the kettle reaches 0.2MPa, open the emptying valve, and the inside of the kettle The pressure is reduced to atmospheric pressure, repeated 3 times, and the emptying is completed. 53% crystalline glucose solution, adjusted to a pH of 8, accurately metered by a high-pressure metering pump, and the volume of the solution added to the reaction kettle is 7m 3 Add hydrogen, turn on the stirrer to stir, and start the hydrogenation reaction at a reaction temperature of 150°C and a reaction pressure of 9MPa;

[0050] Set the pH adjustment range of the online pH meter, the upper limit is 8, and the lower limit is 7.5;

[0051] After reacting for 15 minutes, slowly open the pneumatic switch valve on the upper part of the cooler, so that the glucose (sorbitol) liquid and h...

Embodiment 2

[0054] Add catalyst to the reaction kettle group, the amount of catalyst added is 200kg, lay the bottom, after the catalyst is added, close all valves, feed hydrogen into the reaction kettle, wait until the pressure in the kettle reaches 0.25MPa, open the emptying valve, and the inside of the kettle The pressure is reduced to atmospheric pressure, repeated 3 times, and the emptying is completed. 50% crystalline glucose solution, adjusted to a pH of 7.8, accurately metered by a metering pump, and the volume of the solution added to the reactor is 4.6m 3 Add hydrogen, turn on the stirrer to stir, and start the hydrogenation reaction at a reaction temperature of 140°C and a reaction pressure of 10.5MPa;

[0055] Set the pH adjustment range of the online pH meter, the upper limit is 8, and the lower limit is 7.5;

[0056] After reacting for 15 minutes, slowly open the pneumatic switch valve on the upper part of the cooler, so that the glucose (sorbitol) liquid and hydrogen gas ar...

Embodiment 3

[0059] Add catalyst in the reaction kettle group, the amount of catalyst added is 150kg, lay the bottom, after the catalyst addition is completed, close all valves, feed hydrogen into the reaction kettle, wait until the pressure in the kettle reaches 0.3MPa, open the emptying valve, and the inside of the kettle The pressure is reduced to atmospheric pressure, repeated 3 times, and the emptying is completed. 55% crystalline glucose solution, adjusted to a pH of 8, accurately metered by a high-pressure metering pump, and the volume of the solution added to the reactor is 3.5m 3 Add hydrogen, turn on the stirrer to stir, and start the hydrogenation reaction at a reaction temperature of 130°C and a reaction pressure of 11.5MPa;

[0060] Set the pH adjustment range of the online pH meter, the upper limit is 8, and the lower limit is 7.5;

[0061] After reacting for 15 minutes, slowly open the pneumatic switch valve on the upper part of the cooler, so that the glucose (sorbitol) li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com