Epoxy resin vacuum pouring technology for protection gas inflation

A technology of epoxy resin and protective gas, which is applied in the field of epoxy resin vacuum filling and protective gas casting technology, which can solve the problems of low electrical insulation strength, surface curing defects, and imperfect technology, and achieve accurate and reliable process connection and high electrical strength , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

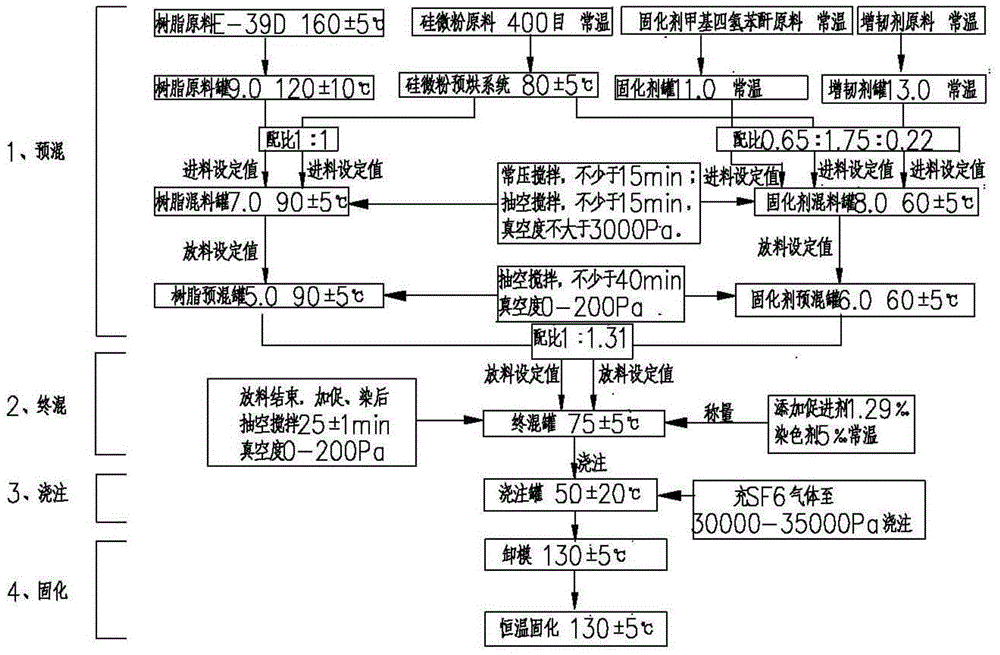

[0019] The epoxy resin vacuum pouring process of this embodiment is as follows: figure 1 Shown:

[0020] (1) Pre-mixing: First, heat the epoxy resin raw material at 120±10°C and the 400-mesh silicon micropowder filler at 80±5°C in a vacuum mixing tank (90±5°C) for pre-mixing, and the epoxy resin The weight ratio of silicon powder and silicon powder is 1:1; in addition, the curing agent methyl tetrahydrophthalic anhydride, toughening agent and silicon powder filler are heated in another vacuum mixing tank (60±5°C) for pre-mixing and curing The weight ratio of methyl tetrahydrophthalic anhydride, isocyanate toughening agent and silica powder filler is 0.65:0.22:1.75: these two premixing processes are carried out simultaneously on two different equipment.

[0021] (2) Final mixing: Put the two premixed materials in the same vacuum mixing tank for final mixing, add organic phosphine accelerator and dyeing agent (organic color paste, H99N-016), heat and vacuum Mix evenly, and ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com